Sensor Solution: Laser Scanners in Automated Conveyor Sorting Systems

- Share

- publisher

- Zoe

- Issue Time

- Sep 25,2024

Summary

Laser Scanner: Installed above the conveyor belt junction to scan the surface height differences of pallets, detecting whether they hold items.

With the continuous advancement of industrial automation and intelligence, the logistics and warehousing sectors are increasingly demanding efficient and accurate sorting systems. Laser scanners, known for their high precision and non-contact measurement capabilities, have gradually become one of the core technologies in automated sorting systems. This proposal explores the application of laser scanners at conveyor belt junctions, facilitating efficient sorting through the detection of pallet items, thereby enhancing overall logistics efficiency.

Application Background and Needs

In the logistics sorting process, pallets on the conveyor belt can either be empty or contain various goods. To optimize operational efficiency, it is essential to quickly and accurately determine the status of each pallet (whether empty) and decide its conveying path:

• Empty Pallets: Divert directly to the empty pallet recovery channel.

• Pallets with Goods: Continue to the next production or packaging stage.

Overview of the Solution

This proposal designs an automated sorting system based on laser scanners, which are installed above the conveyor belt junctions to perform real-time detection of passing pallets. By scanning, the system determines whether a pallet is empty, thereby deciding its conveying path.

System Components

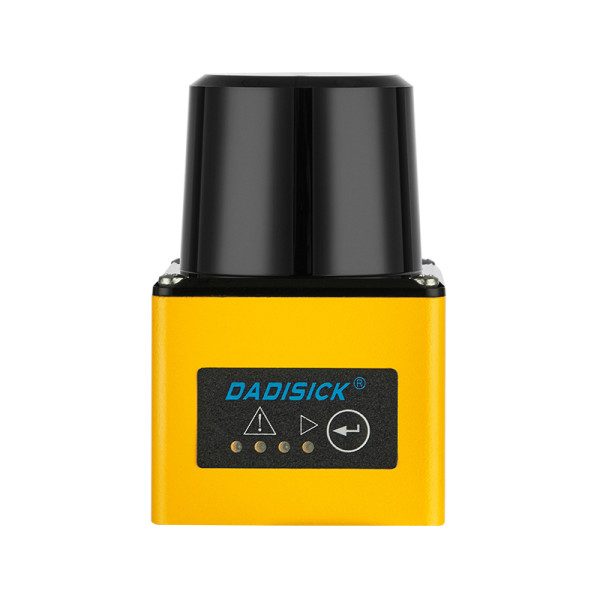

• Laser Scanner: Installed above the conveyor belt junction to scan the surface height differences of pallets, detecting whether they hold items.

• Conveyor Belt: Transports pallets to the junction, where the feedback from the laser scanner determines the conveying path.

• Control System: Directly controls the diversion of the conveyor belt based on the laser scanner's detection results:

1️⃣Empty pallets are diverted into the recovery channel.

2️⃣Pallets with goods are transported to the next stage.

• Actuation Mechanism: The mechanical actuation at the conveyor belt junction guides pallets into different channels based on control signals.

Working Principle of the Laser Scanner-Based Conveyor Sorting System

The laser scanner continuously scans the pallets as they pass through, utilizing laser reflections to obtain distance information regarding the pallet surfaces. This height information is sent to the control system, which determines if the pallet is empty during scanning. If an empty pallet is detected, the control system instructs the conveyor belt to divert it into the empty pallet recovery channel. Conversely, if goods are detected on the pallet, it continues on to the next stage. The entire process operates fully automatically, ensuring rapid and precise sorting without manual intervention.

Advantages of the Proposed Solution

• The laser scanner provides millimeter-level accuracy, ensuring even small items are accurately detected.

• It can quickly scan and assess pallets, allowing for the detection of a large number of pallets per minute, greatly improving sorting efficiency.

• The system operates fully automatically, relying on the interaction between the laser scanner and the control system, minimizing human error and lowering labor costs.

• Laser scanners can flexibly adjust detection parameters according to different types of pallets and goods, accommodating various application scenarios to meet diverse logistics needs of businesses.

Recommended Laser Scanners

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

20m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Sensing range 20m, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Economic Laser Scanning Radar sensing range 5m-10m