TOF Long-range Laser Distance Sensor DS Series: Measure Farther, Perceive Sharper!

- Share

- publisher

- Zoe

- Issue Time

- Nov 29,2024

Summary

The DADISICK DS series TOF long-range laser distance sensors, with their high precision, long measurement range, fast response, and excellent anti-interference capabilities, have demonstrated unique advantages in numerous fields. They have become indispensable technological tools, particularly in automation, robotics, traffic monitoring, and engineering measurement applications.

DADISICK New Product | TOF Long-range Laser Distance Sensor DS Series

DS Series Long-range Laser Distance Sensor

The DS series long-range laser displacement sensors enable high-precision point measurement within a 200-meter range, with a distance accuracy of up to ±2mm. These sensors are equipped with an intuitive control panel and status indicators, supporting quick and easy installation. Unlike conventional phase measurement sensors, the DS series supports a measurement frequency of up to 1000Hz, making it particularly suitable for precise positioning and measurement of high-speed moving objects. It is an essential sensor for automated warehousing, logistics, and vehicle systems.

ASRS System

Lifting or Hoisting Devices

Automated Parking Systems

Port Automation

Specifications

|

Basic Information

|

|||

|

Product Name

|

DS Series Long-Range Laser Distance Sensor

|

||

|

Model

|

DS-80

|

DS-120

|

DS-200

|

|

Measurement Characteristics

|

|||

Measurement Range (with retroreflector) | 80 m | 120 m | 200 m |

Typical Spot Size | 100 mm (@80m) | 150 mm (@120 m) | 245mm (@200 m) |

Measurement Accuracy | ±2 mm | ||

Repeatability | 1 mm | ||

Measurement Frequency | 1000 Hz | ||

Measurement Resolution | 0.1 mm | ||

Maximum Moving Speed | 15 m/s | ||

Optical Characteristics | |||

Supply Voltage | DC 9 V...30 V | ||

Operating Current | 0.2 A/12 V DC | ||

Laser Source | Red Laser (Visible Light) | ||

Power Consumption | 2.4 W (MAX) | ||

Others | |||

Data Transmission Interface | SS1, Ethernet 100BASE-TX | ||

Indicators | PWR Indicator, MF1/MF2 Status, LNK Indicator, BUS Indicator | ||

Display | OLED Screen (128 x 64 pixels) | ||

Network Interface | M12/4-pin/D-type female straight | ||

Power/SSI Interface | M12/8-pin/A-type male straight | ||

Ambient Light Resistance | ≤100,000 lx | ||

Operating Temperature | -10°C ~ +55°C | ||

Storage Temperature | -30°C ~ +75°C | ||

Humidity | <80% | ||

Protection Rating | IP65 | ||

Dimensions | 123 x 69.5 x 90 (mm) | ||

Weight | 600 g (excluding cable) | ||

The Application Fields Of The DS Series Laser Displacement Sensors

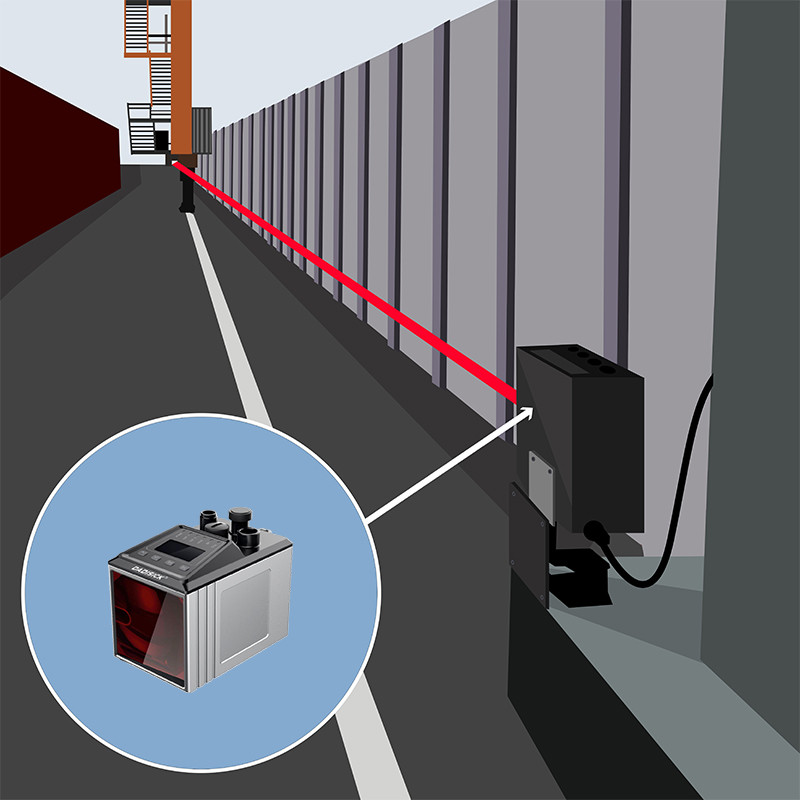

Crane Collision Prevention in Material Handling

In material handling operations, multiple cranes are often required to work in coordination. Without an effective protection and warning system, cranes running on the same track could collide. To address this, we use Time-of-Flight (TOF) technology, installing DS-80 medium-range laser measurement sensors on both sides of each crane. These sensors can accurately detect nearby cranes and fixed obstacles (such as walls) within a maximum range of 80 meters. Each crane is also equipped with a reflector to ensure proper sensor function. It is worth mentioning that these sensors can operate stably even in high-temperature environments up to +55°C, ensuring safety and efficiency during the material handling process.

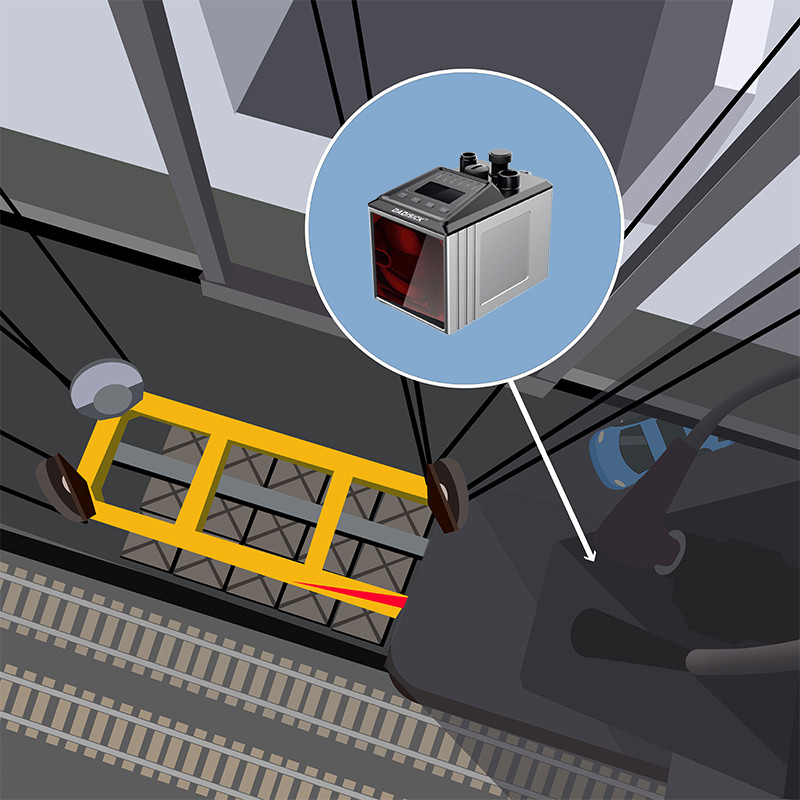

Precise Measurement of Crane Height and Position

To ensure the safe operation of lifting equipment within its working area and to avoid collisions with other objects, we have introduced the DS-200 long-range laser sensor. This sensor can provide real-time, accurate information about the crane’s current position. With its superior performance, the DS-200 achieves high-precision non-contact distance and speed measurement. Additionally, it is equipped with a configurable Ethernet 100BASE-TX/SS1 interface, ensuring outstanding performance in outdoor environments and adaptability to various working conditions.

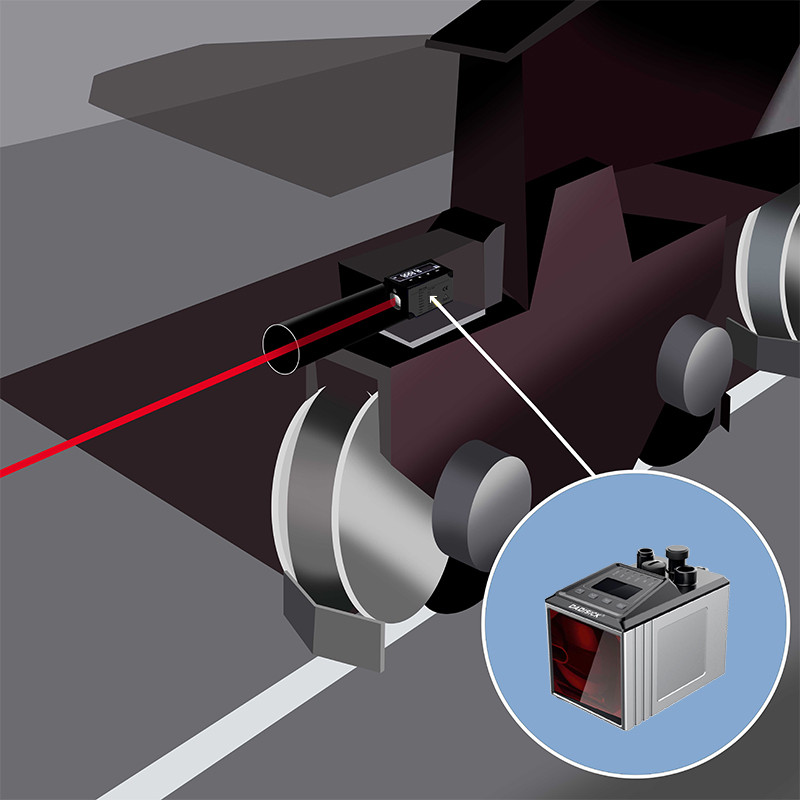

Collision Prevention Solution for Gantry Cranes

For Ship-to-Shore (STS) cranes, it is crucial to maintain a safe distance between cranes during operation to prevent collisions. To address this, we have implemented the DS-200 long-range laser sensor. This sensor precisely measures the distance between cranes, effectively preventing collision accidents. The installation process is simple and quick, and the DS-200 provides real-time monitoring. If the distance between cranes reaches a preset limit or the speed exceeds the safe range, the sensor immediately sends a signal to the higher-level control system. Additionally, the DS-200 is equipped with a configurable Ethernet 100BASE-TX/SS1 interface, providing real-time data related to distance and speed, ensuring the safe operation of the cranes.

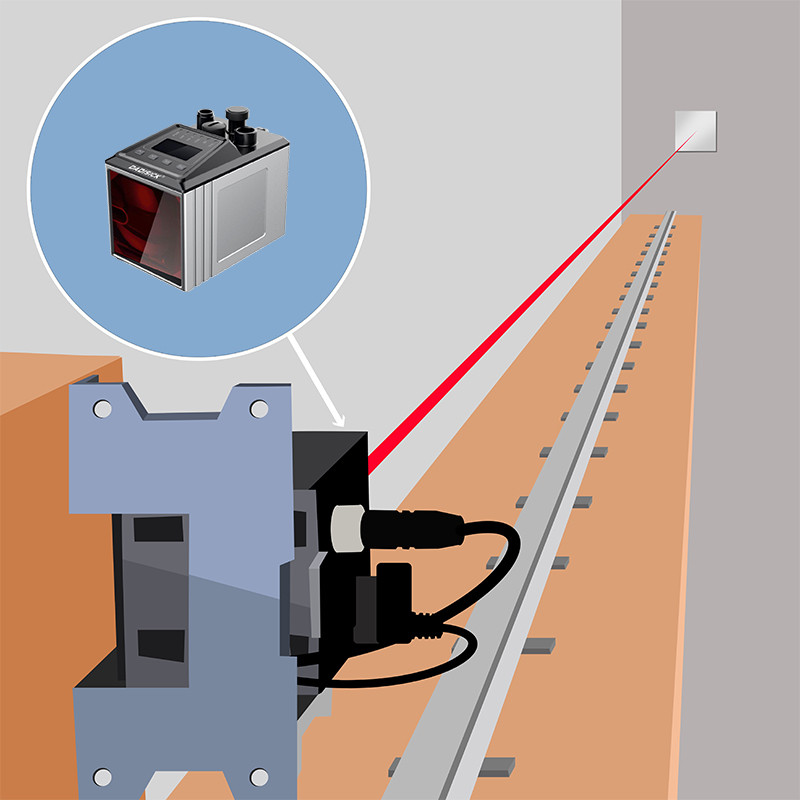

Precise Positioning of Bridge Cranes in Scrap Yards

To ensure the safe and precise operation of bridge cranes in scrap yards and prevent collisions with warehouse walls, we have equipped each crane with two DS-120 long-range laser sensors. These sensors use advanced laser measurement technology to achieve high-precision positioning of the crane and hoist. The rugged design of the sensors not only ensures stable operation in harsh environments but also reduces maintenance costs while maintaining high availability.

Furthermore, when two parallel DS-120 sensors are installed on the same crane, they enable precise monitoring of synchronized control for the bridge crane, further enhancing operational safety and efficiency.

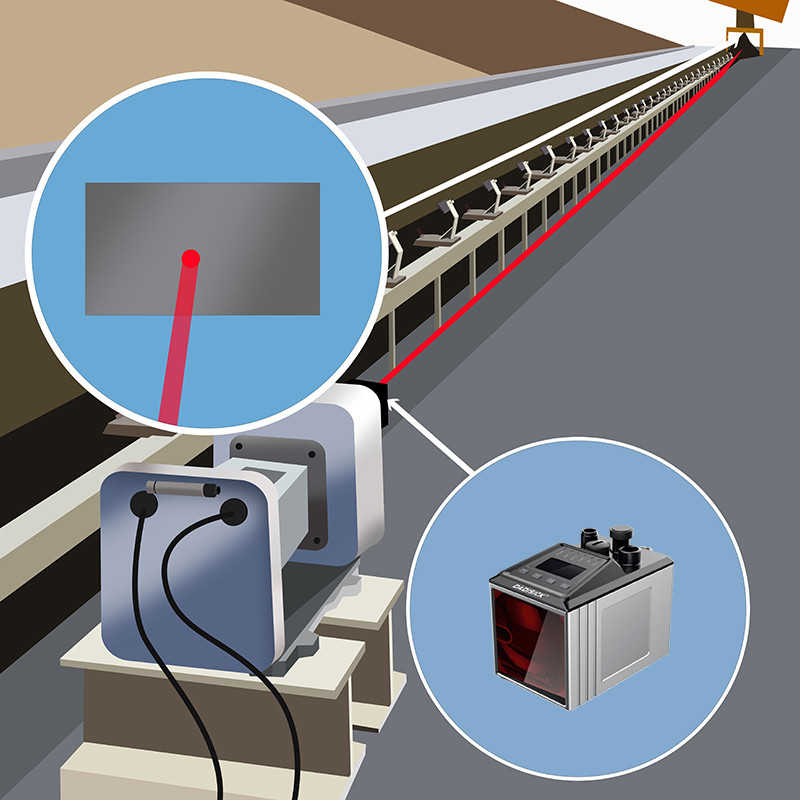

Positioning of Stacker and Reclaimer Machines

The DS-200 non-contact laser distance sensor can accurately measure the position of stacker and reclaimer machines within a 200-meter range, both indoors and outdoors, ensuring precise equipment scheduling and operation.

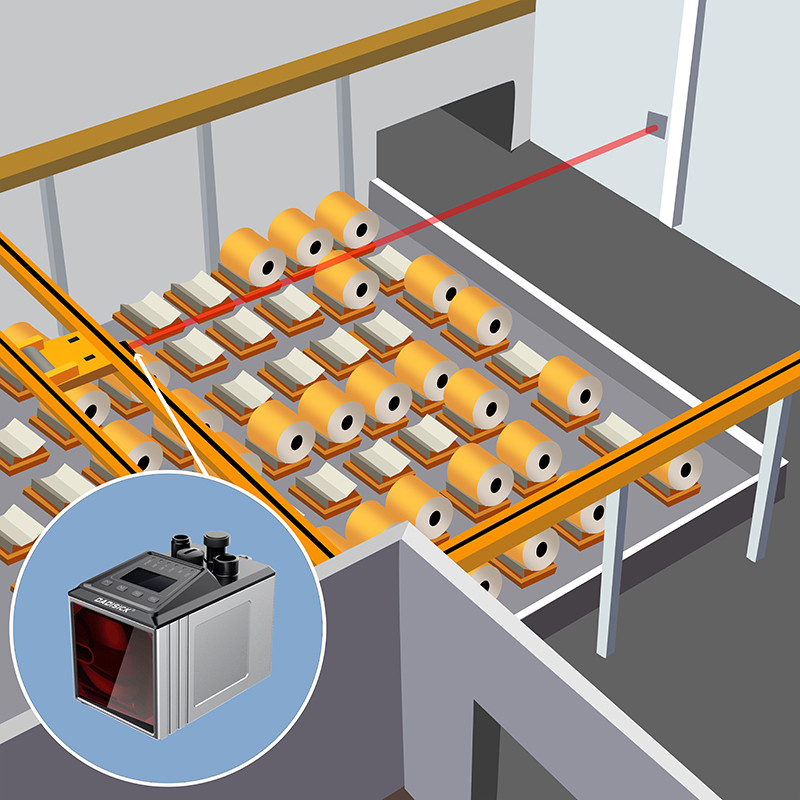

Precise Positioning of Industrial Cranes in Warehouses

The DS series laser sensors, with medium and long-range measurement capabilities of 80/120/200 meters, can accurately guide industrial cranes used for controlling, transporting, and re-stacking finished paper products. With their excellent measurement reliability, these sensors ensure ultra-high precision positioning for industrial cranes. Combined with a wide scanning range, impeccable reliability, high-precision measurement capability, and affordable price, DADISICK's distance sensors are undoubtedly the ideal choice for optimizing internal material handling processes.

Related Laser Distance Sensors

Measuring frequency: 1000Hz

Data transmission interface: SSl, Ethernet 100 BASE-TX

Measuring distance: 200m

Measurement accuracy: ±2 mm

Measuring frequency: 1Hz-40Hz

Communication interface: RS232/RS485 (switchable)

Measuring distance: 0.2-100m

Measurement resolution: 1mm

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Measure distance: 0.1-50m

Measuring frequency: 1000Hz

Data transmission interface: SSl, Ethernet 100 BASE-TX

Measuring distance: 80m

Measurement accuracy: ±2 mm