The Application of Safety Edges in AGVs (Automated Guided Vehicles)

- Share

- publisher

- Zoe

- Issue Time

- Aug 12,2024

Summary

A safety edge, is a band-shaped pressure-sensitive switch made of rubber. It is usually composed of soft, flexible materials, which allows it to adapt to various installation environments. The primary function of a safety edge is to prevent automated equipment (such as industrial robots, AGV trolleys, machine tool workbenches, and electric doors) from causing harm to operators or other objects during operation.

What is AGV?

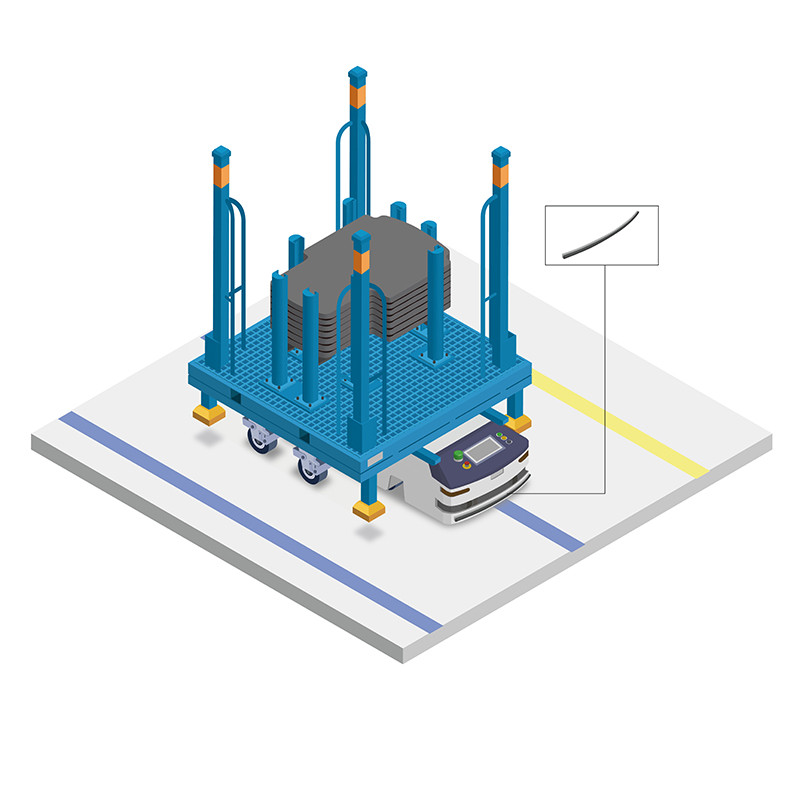

AGV stands for Automated Guided Vehicle, a type of transportation robot controlled by automation and computer systems, widely used in the warehousing and logistics sector. Compared to traditional methods that rely on manual labor for loading, unloading, and distributing goods, AGVs free up human resources by automating the tasks of moving goods and materials. This not only improves the accuracy and timeliness of deliveries but also significantly enhances distribution efficiency while effectively reducing labor costs.

Working Principle of AGVs

AGVs primarily operate based on their automated guidance systems, which may include electromagnetic tracks, safety laser scanners, or inertial navigation systems. For example, in the case of a laser-guided AGV, its working principle involves using a safety laser scanner to identify pre-positioned reflectors in the environment, obtaining the current position and orientation information. The AGV then combines this data with its built-in map to calculate the optimal path to the destination and drives its wheels forward through a control system. During movement, the AGV continuously updates its position and orientation, adjusting the route in real-time to ensure accurate arrival at the predetermined destination. Additionally, AGVs are equipped with obstacle avoidance functions, allowing them to automatically stop or detour when encountering obstacles, ensuring safe operation.

The main functions of AGVs include material handling, shelf restocking within warehouses, and order picking. In manufacturing, AGVs are widely used for automated material handling and logistics operations on production lines. In warehousing and logistics, AGVs help achieve automated goods transportation, reducing labor costs and improving operational efficiency. Beyond these areas, AGVs also play important roles in industries such as healthcare, electronics manufacturing, food and beverage, aerospace, and retail.

The Application of Safety Edges in AGVs (Automated Guided Vehicles)

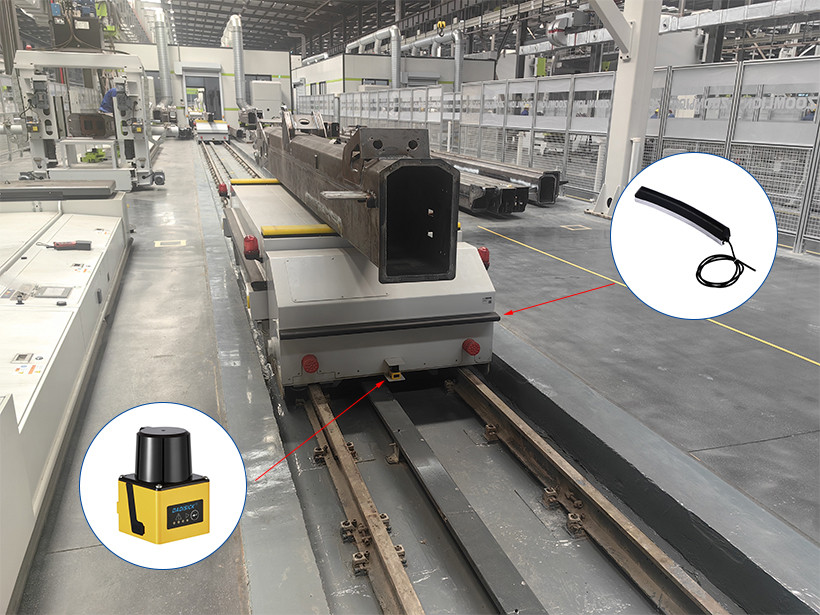

Safety edges, also known as bump strips, are pressure-sensitive switches typically made of flexible, bendable rubber strips designed to adapt to various installation environments.

Their primary function is to provide safety protection, preventing automated equipment—such as industrial robots, AGVs, machine tool workbenches, and electric doors—from causing harm to operators or other objects during operation. When a safety edge is pressed, it generates a signal that is transmitted to the equipment’s central controller. Upon receiving the signal, the controller immediately implements appropriate safety measures, such as emergency stopping or changing the direction of movement.

The significance of installing safety edges lies in the fact that AGVs typically use 2D lasers to sense their surroundings, which can only detect objects within the laser plane. However, in real-world scenarios, there may be three-dimensional obstacles with protruding lower parts that appear on the AGV’s path, which the laser cannot detect. In such cases, the protruding lower part would make contact with the safety edge, and once triggered, the AGV would immediately stop. Therefore, safety edges are usually installed on planes that the laser cannot scan, often at a lower height, and are equipped both at the front and rear of the robot.

Recommended Safety Edges

✅ High sensitivity safety edges

✅ Sensor length range: 200mm-6000mm

✅ Flexible design, suitable for various machine protection scenarios

✅ Protection level: IP65; Operating temperature: -20°C to 55°C

✅ Mechanical lifespan: >3,000,000 cycles

✅ Outer casing made of EPDM and CR rubber, resistant to various chemical corrosions, suitable for use in factories, general industrial environments, and civilian settings

Related Safety Protection Products

Safety Edges is a technology that monitors the pressure distribution on the carpet through pressure sensing.

Safety carpet is a technology that monitors the pressure distribution on the carpet through pressure sensing.

20m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.