What is a Safety Relay? Understanding Its Core Features and Industrial Applications

- Share

- Issue Time

- Jun 16,2025

Summary

Discover how safety relays enhance industrial safety with dual-channel redundancy, fault detection, and fail-safe designs. Learn their core functions, working principles, and applications across automated production lines, emergency stop systems, safety door monitoring, and light curtain protection. Explore Dadisick's high-quality safety relays for reliable workplace protection.

What is a Safety Relay?

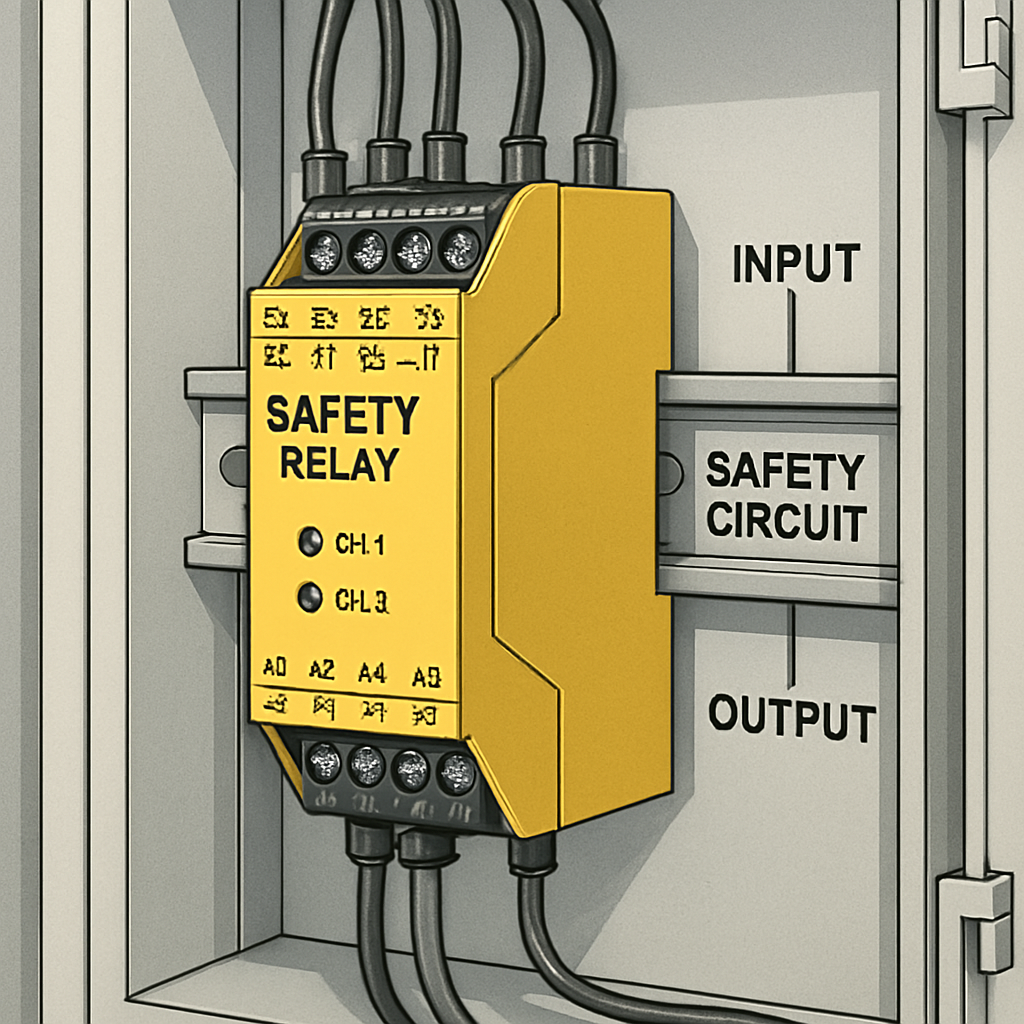

A safety relay is an electrical device specifically engineered for industrial safety systems. Its primary role is to monitor and control the safety functions of machines and equipment, ensuring they stop reliably or execute protective measures when a dangerous situation is detected. Unlike standard relays, safety relays feature dual-channel redundancy and fail-safe mechanisms, guaranteeing operational safety even if a component fails.

In the event of equipment malfunctions or personnel operational errors, there is a risk of severe accidents. Safety relays were developed to meet these safety needs. They are designed to monitor various safety signals, such as emergency stop buttons, safety doors, and light curtains, and promptly trigger protective measures to prevent accidents and ensure the safety of both personnel and equipment. When these devices detect an anomaly—like an operator entering a hazardous zone—the safety relay cuts power or triggers a safety response to prevent accidents.

How Does a Safety Relay Work?

The functionality of a safety relay hinges on its redundant design and self-monitoring capabilities, which ensure safety even in the face of faults. Here’s a breakdown of its key operating principles:

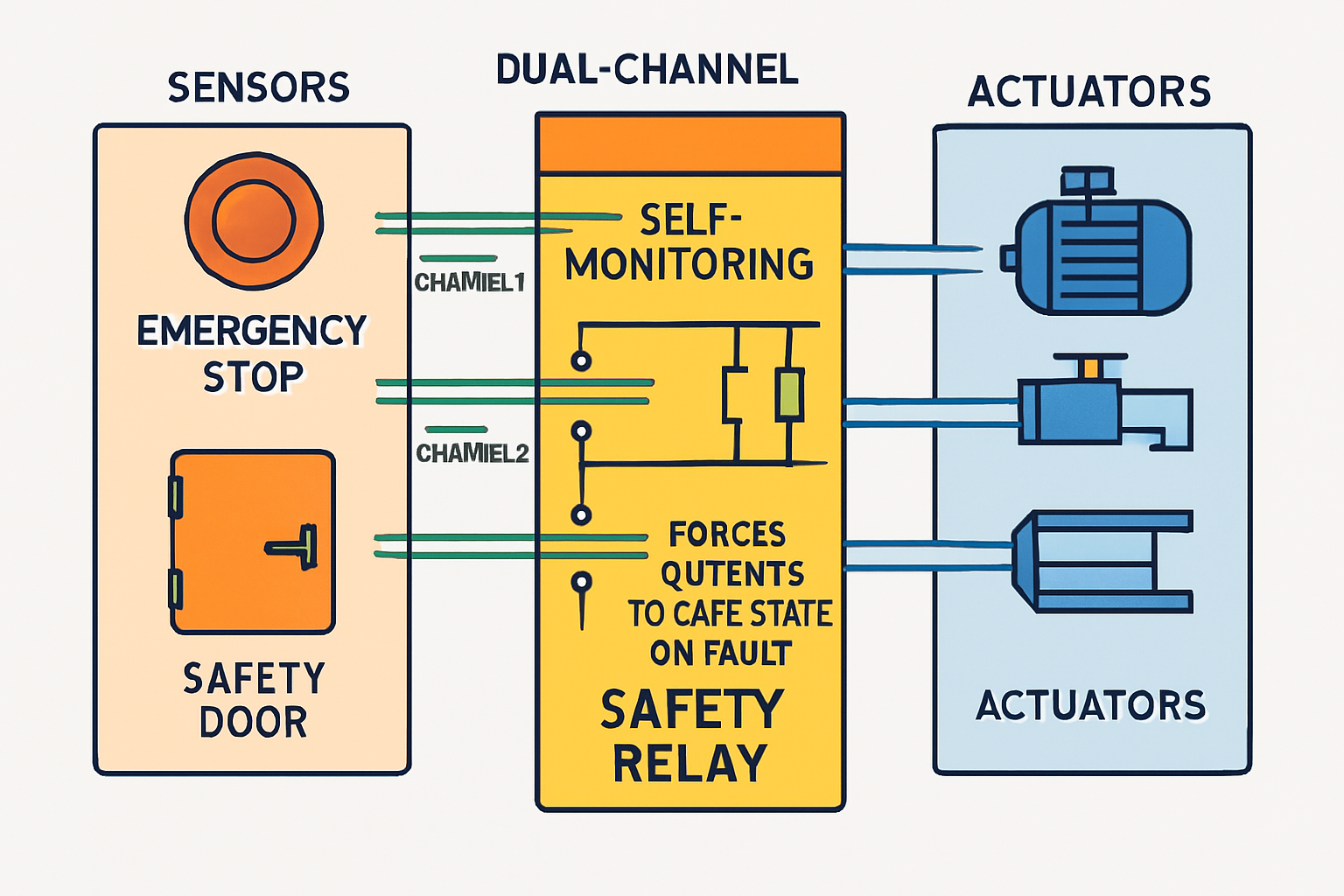

Dual-Channel Redundancy

Safety relays adopt a dual-channel redundancy design, meaning they utilize two independent circuit channels to monitor safety signals. These two channels operate independently of each other, continuously receiving and processing safety signals. For example, when a worker presses an emergency stop button, both channels will immediately detect the signal. If one channel fails to function properly due to a fault, the other channel can still reliably transmit the signal, ensuring the safety function remains intact. This dual-channel redundancy significantly enhances the reliability of the system and reduces the risk of safety failures caused by single-point failures. In practical applications, this design effectively addresses potential issues such as circuit open circuits or short circuits, providing robust safety assurance for industrial production.

Fault Detection and Self-Monitoring

Safety relays are equipped with advanced built-in fault detection mechanisms that enable continuous self-monitoring. They can monitor various parameters and status information of their internal circuits in real time, such as voltage, current, temperature, and signal transmission. Once an abnormality, such as a short circuit, open circuit, or component failure, is detected, the relay will immediately take action. It will swiftly switch to a safe state, such as cutting off power to the actuators or locking the control circuit, thereby halting the operation of the machinery. This fault detection and self-monitoring capability allow safety relays to proactively identify potential safety hazards and promptly respond, effectively preventing accidents caused by undetected internal faults. This ensures the safe operation of the equipment and provides users with a high level of safety assurance.

Fail-Safe Design

The fail-safe design philosophy is deeply embedded in the core of safety relays. Under normal operating conditions, the relay ensures the proper functioning of the equipment by monitoring safety signals and controlling the execution of safety functions. However, in the event of any failure—whether internal or external—the relay will immediately default to a predefined safe action. Common safe actions include cutting off power to motors, disabling actuators, or activating braking devices. For instance, in a production line where a safety relay controls the operation of a robot, if the relay detects a fault that could potentially endanger personnel or equipment, it will immediately stop the robot's power supply, bringing it to a halt. This fail-safe design guarantees that the system remains in a safe state under all circumstances, minimizing the risk of accidents and providing robust safety protection for industrial production environments.

Applications of Safety Relays in Industrial Safety Systems

Safety relays are indispensable across various industrial environments, particularly in manufacturing, automated production lines, and robotic systems. Here are some common applications:

•Emergency Stop Functions: Pressing an emergency stop button prompts the safety relay to instantly disconnect power, halting machinery to prevent harm.

•Safety Door Monitoring: Safety relays ensure machines only operate when safety doors are closed, protecting operators from moving parts.

•Light Curtain Protection: In hazardous zones, light curtains paired with safety relays stop machines if a person or object crosses the boundary.

•Safety Mat Activation: Stepping on a safety mat triggers the relay to shut down equipment, safeguarding workers in the vicinity.

These examples illustrate how safety relays are critical to maintaining a secure industrial workplace.

Dadisick: Your Partner in Industrial Safety

Dadisick is a trusted name in industrial safety solutions, offering a wide range of products, including safety relays, light curtains, and safety mats. With a mission to safeguard people and equipment in industrial settings, Dadisick delivers reliable, high-quality safety solutions tailored to diverse needs.

Detection range: 0.3-3m

Detection: Fingers, Hands

Security Level: IP65

This safety light curtain features an ultra-thin front design with a thickness of only 15 millimeters, making it an ideal safety protection device for hazardous locations with limited installation space or special requirements. Its response time is extremely short, reaching an industry-leading level of ≤15 milliseconds, ensuring a quick response in case of dangerous situations. It can be customized according to specific user needs, allowing configuration based on particular application requirements for height and resolution. This provides a more flexible and precise protection solution.Why Choose Dadisick Safety Relays?

•Unmatched Reliability: Featuring advanced redundancy and fail-safe designs, Dadisick safety relays provide dependable protection in any scenario.

•Cutting-Edge Innovation: Continuous R&D ensures Dadisick products meet the latest safety standards, keeping your operations compliant and secure.

•Exceptional Support: Dadisick offers expert technical guidance and after-sales service, ensuring seamless integration and optimal use of safety equipment.

Real-World Example

In practical industrial settings, safety relays are widely used in various equipment and scenarios, such as metalworking machine tools, packaging machinery, elevators, and automated production lines. Their advantages are evident. First and foremost, safety relays offer high reliability due to their dual-channel redundancy, fault detection, and self-monitoring features. They can effectively prevent safety failures caused by internal faults, ensuring stable operation over extended periods. In an automotive manufacturing plant, Dadisick safety relays were paired with light curtains to protect workers from robotic arms. When a worker inadvertently entered the danger zone, the light curtain signaled the relay, which instantly powered down the arm—demonstrating the efficiency and reliability of Dadisick’s solutions.

Conclusion

Safety relays are a cornerstone of industrial safety systems, offering robust protection through redundant designs and fail-safe mechanisms. From emergency stops to light curtain integration, they ensure machines and workers remain safe across countless applications.

Dadisick provides premium safety relays and comprehensive support, empowering businesses worldwide to create safer workplaces. Curious to learn more about how safety relays or Dadisick products can enhance your operations? Visit our official website for additional details.

Related Hot-sale Safety Relay

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

Economical safety relay, dual-channel safety monitoring circuit design, suitable for high-demand fields such as mechanical protection, automated production lines and robot systems.

LS-3A1B.C is a safety relay suitable for emergency stop, safety door, PNP type safety light curtain signal of various mechanical equipment. It has 3 normally open (NO) safety output contacts and 1 normally closed (NC) auxiliary output contact, and can select single/dual channel operation, manual/automatic reset and short circuit monitoring between channels. It adopts the design of components produced in China, standard housing, convenient wiring and common with mainstream products in the market, with excellent cost performance.

DADISICK LS-2A4S is a configurable safety control module that supports a variety of switch-type safety element inputs (such as emergency stop buttons, safety doors, two-hand buttons, etc.), and supports up to 6 safety element inputs, 2 relay safety outputs, and 4 semiconductor outputs. It can use configuration software to set safety control logic to meet a variety of on-site application requirements.

The QSRN safety relay module meets the safety requirements of EN/ISO13849-1Cat.4 and is suitable for monitoring various signals in industrial sites with high safety requirements – including emergency stop signals, safety door switch signals, safety light barrier signals, and safety light curtain signals. Outside the two-hand button signal.