Summary

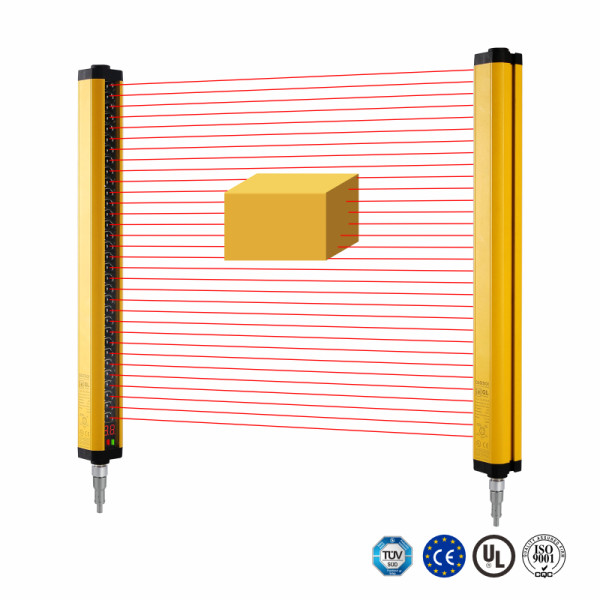

Our client is a logistics giant specializing in goods sorting and transportation. They operate large-scale belt conveyor systems globally to meet the growing demands of logistics. With the expansion of their business, they began to focus on the safety of their operations, especially when interacting with automated belt conveyor systems.