DADISICK LiDAR: Enabling Accurate Collision Warning and Navigation for AGVs and Forklifts

- Share

- publisher

- Zoe

- Issue Time

- Sep 13,2025

Summary

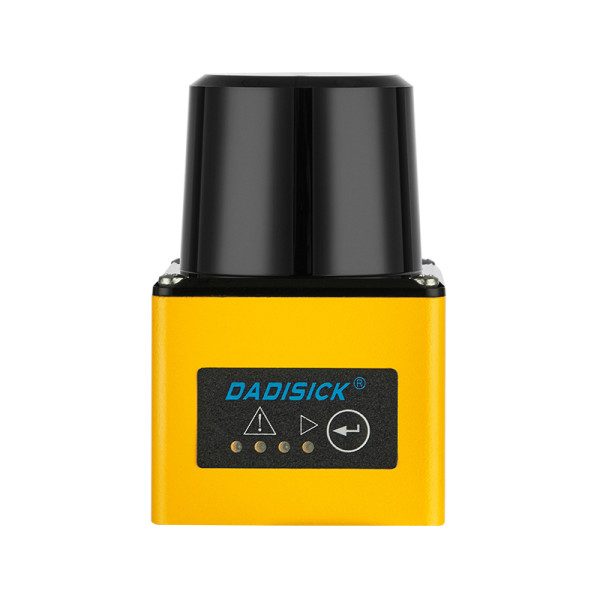

The DADISICK LDS2030B5-5S 2D LiDAR delivers high-precision TOF measurement, 300° scanning, and 25Hz refresh, making it ideal for forklift collision avoidance and AGV laser navigation. Compact, reliable, and cost-effective, it ensures safe obstacle detection and seamless system integration.

In modern warehousing and logistics, forklift collision avoidance systems and AGV laser navigation are critical to ensuring both safety and efficiency. Many AGV and forklift manufacturers, as well as system integrators, are exploring how to use 2D LiDAR sensors to enhance real-time environmental perception, enabling advanced forklift collision detection systems and collision warning systems.

By emitting laser pulses and measuring their time of flight (TOF), LiDAR sensors can capture precise distance information and build a map of the surrounding environment in real time . For example, in automated guided vehicles (AGVs), scanning LiDAR sensors not only provide high-precision positioning for navigation but also detect obstacles and adjust the path automatically to avoid collisions.

The DADISICK LDS2030B5-5S single-layer scanning LiDAR is designed with this principle in mind. It uses TOF measurement, provides a 300° scanning range, 0.5° angular resolution, and a 25 Hz scanning frequency. It supports Ethernet and I/O interfaces, making it highly adaptable for integration in AGVs and forklifts. This article introduces how the LDS2030B5-5S enhances forklift collision avoidance and AGV laser navigation from a technical and application perspective.

Forklift Collision Avoidance — Operator-Assisted Safety

Goals and Features

The primary objective is to protect drivers, pedestrians, and goods. The system functions mainly as an assistive and warning tool rather than fully replacing human judgment.

It emphasizes short-range, low-latency alerts, such as audible/visual warnings, speed limitation, or in some cases automatic braking or enforced deceleration, while keeping the operator’s control authority as the priority.

Perception and System Requirements

● Must reliably detect both static and dynamic obstacles at short distances (racks, pallets, personnel) and support multi-level alarm zones (warning zone / danger zone / stop zone).

● Requires stable short-range measurement with low false-alarm strategies (e.g., filtering reflections from forks or pallets attached to the vehicle).

● Interfaces with the vehicle’s controller/brake system should be simple and direct: local I/O outputs can trigger emergency deceleration or buzzers, enabling rapid disconnection or speed limitation.

Typical Installation and Integration

● In addition to front-mounted configurations, the LiDAR can also be installed at the rear of the forklift, as shown in the example, specifically to monitor the rear area during reversing and prevent collisions with people or obstacles.

● A combined front-and-rear deployment can fully cover the forklift’s blind spots: front for detecting goods and racks, rear for reversing paths and pedestrians.

● Recommended setup includes one or two sensors, combined with low-latency I/O outputs, and configured software-side for short-range, high-frequency warning logic.

LDS2030B5-5S Advantages

● Compact size allows flexible front or rear installation; 300° field of view with 0.5° angular resolution covers both driving direction and side blind spots.

● 25Hz refresh rate with TOF measurement enables fast short-range alerts; Ethernet + I/O interfaces support integration with on-board ECU or local alarm/brake circuits, meeting forklift “rapid local response” requirements.

AGV Laser Navigation and Obstacle Avoidance — Autonomous Decision-Making

Goals and Features

AGVs are built around autonomous navigation, where perception results are directly used for localization/mapping (SLAM), path planning, and real-time replanning. Sensor data must be continuously consumed and fused by algorithms.

The system must balance navigation efficiency and safety constraints: when encountering obstacles, an AGV may dynamically reroute, replan its path, or stop, rather than simply issuing a warning.

Perception and System Requirements

● Emphasizes coverage and data continuity: LiDARs are typically mounted on the top or multiple points on the vehicle, fused with odometry and IMU for stable pose estimation.

● Latency tolerance is higher than forklifts, but data integrity, Ethernet bandwidth, and synchronization are more critical to support SLAM and efficient path planning.

● The system must support obstacle classification (static/moving), trajectory prediction, and interaction with higher-level scheduling (fleet managers).

Typical Installation and Integration

● Commonly mounted on the roof or high positions of the vehicle to gain an unobstructed field of view and reduce occlusions; multi-sensor fusion can achieve near 360° perception.

● LiDAR outputs are integrated into the navigation stack (via Ethernet/ROS), working in layered coordination with docking, task scheduling, and safety subsystems.

● For high-speed or dense environments, additional sensors or redundant perception can enhance robustness.

LDS2030B5-5S Advantages

● 300° field of view and 0.5° resolution provide wide-angle point cloud input with one or a few sensors; Ethernet interface ensures smooth integration into SLAM/navigation systems.

● 25Hz refresh rate and TOF accuracy are sufficient for dynamic obstacle avoidance and replanning at typical indoor AGV operating speeds.

● Compact size allows flexible top or side mounting, achieving a balance between cost and coverage.

Why Choose DADISICK LDS2030B5-5S for AGVs and Forklifts

The DADISICK LDS2030B5-5S LiDAR provides a balance of performance, cost-effectiveness, and ease of integration, making it ideal for forklift collision avoidance systems and LiDAR-based AGV navigation.

Core Features:

● High-precision TOF measurement: Typical system error of only ~2 cm.

● Wide field of view: 300° scanning range with 0.5° angular resolution captures even small objects.

● Fast refresh rate: 25 Hz scanning frequency ensures quick reaction to dynamic obstacles.

● Rugged design: IP67-rated housing with dust, water, sunlight, and fog resistance.

● Compact and lightweight: Only 80 × 85 × 102 mm and 0.6 kg, ideal for vehicle integration.

● Flexible connectivity: Ethernet and I/O interfaces simplify integration into AGV and forklift control systems.

● Cost-effective: Optimized for AGV obstacle avoidance and forklift safety, balancing performance with affordability.

LiDAR-based safety and navigation solutions are now indispensable for modern intralogistics. The DADISICK LDS2030B5-5S provides wide-angle scanning, fast measurement, and compact integration — making it an ideal choice for forklift collision avoidance systems, forklift collision warning systems, and AGV laser navigation applications .

With its combination of cost-effectiveness, performance, and adaptability, the LDS2030B5-5S helps manufacturers and system integrators build safer, smarter, and more efficient automated systems.

Related Product

Sensing range 20m, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Economic Laser Scanning Radar sensing range 5m-10m

20m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.