High-Precision In-line Measuring Light Curtain QL Series — The Perfect Partner for In-Motion Checkweighers

- Share

- publisher

- Zoe

- Issue Time

- Aug 26,2025

Summary

Measuring Light Curtain + In-Motion Checkweigher — The Dual Engine for Cost Reduction and Efficiency in E-Commerce Logistics under "Volumetric Pricing".

Industry Background

With volumetric pricing now widely adopted, real-time collection of both weight and dimensions has become a must for courier companies and e-commerce warehouses.

Billing: Charges are based on the greater of volumetric or actual weight. The more accurate the data, the clearer the profit.

Loading: Truck and container space utilization can increase by 8%–15%.

Sorting: Items are routed by size/weight, reducing manual rechecks and boosting efficiency by over 30%.

Technology Overview

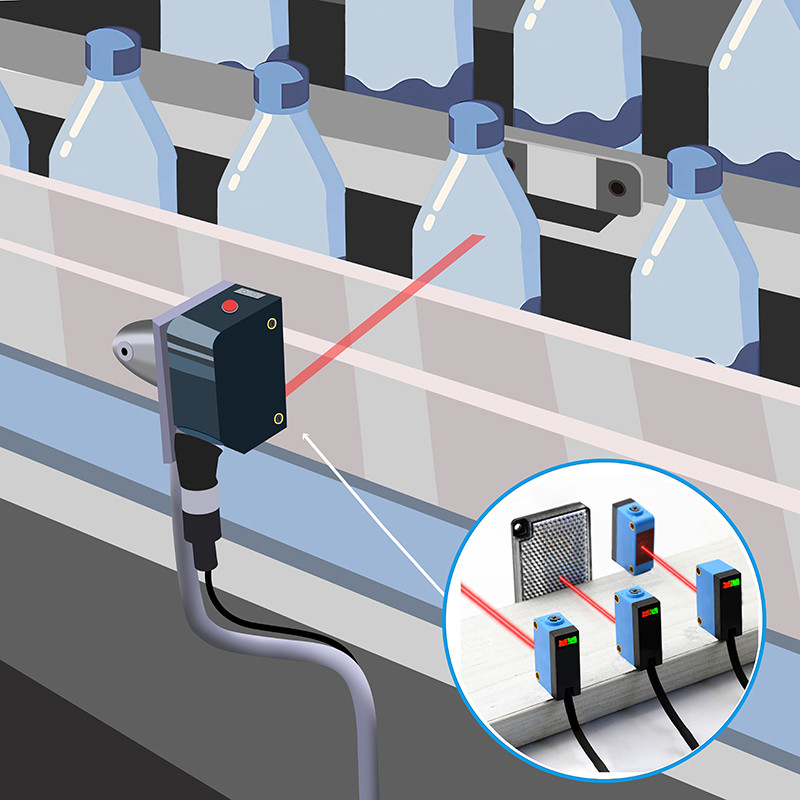

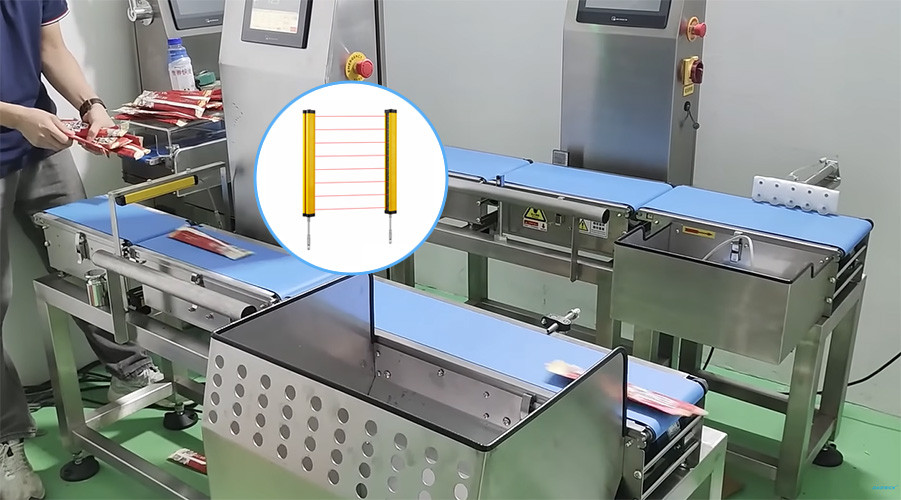

Measuring Light Curtain QL Series

The Measuring light curtain creates a dense grid of infrared beams. When a package passes through, the system detects interruptions in the beams to accurately reconstruct its length, width, and height. By using a crossed-beam array, it can capture 3D dimension data in real time, even for irregularly shaped parcels.

● Detection width: as small as 5 mm, edge resolution 2.5 mm

● High gain → reliably detects semi-transparent, black, reflective, and other challenging packages

● By using three sets of measuring light curtains to form a crossed-beam array, the system outputs real-time 3D data of length, width, and height.

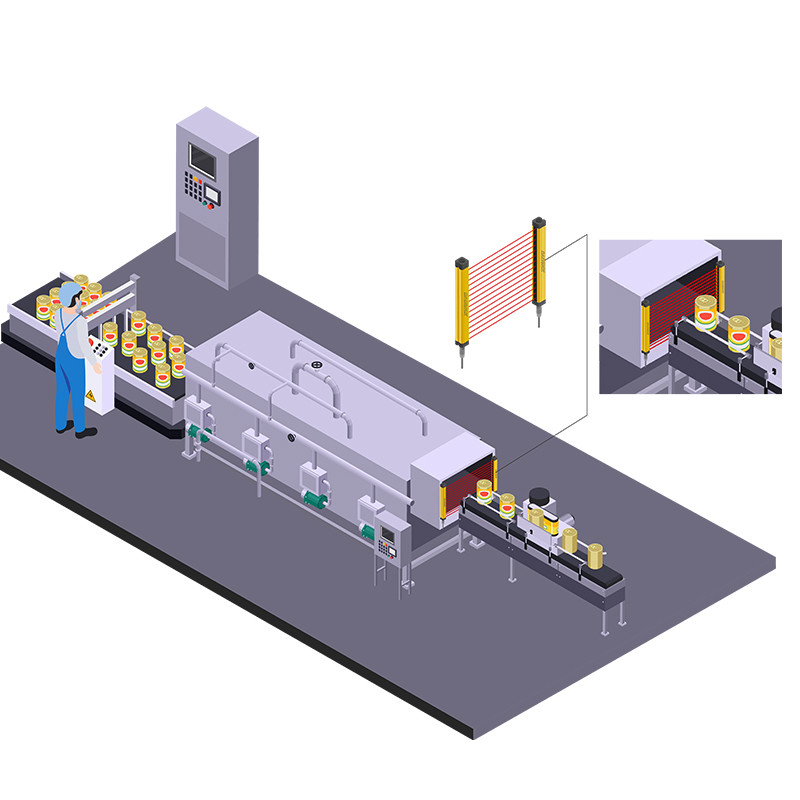

The Perfect Integration Of Measuring Light Curtains And In Motion Checkweighers

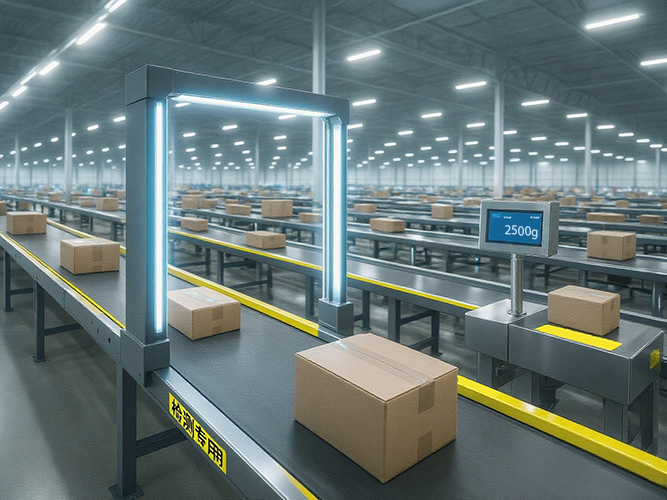

The in-motion checkweigher integrates a high-speed conveyor with precision weighing cells. As packages move across the scale without stopping, the system captures accurate weight data instantly. Combined with dimension data, it provides a complete weight–volume profile for each package.

● Dynamic accuracy: ±0.5 g (range 10 kg) / ±5 g (range 30 kg)

● Dynamic accuracy: ±0.5 g (range 10 kg) / ±5 g (range 30 kg)

● Real-time weight and dimension data can be directly integrated with WMS/WCS via TCP/IP, Modbus TCP, Profinet, etc.

● One-button self-check, calibration, and taring; maintenance time < 2 min

Integrated Workflow

1️⃣ Package enters high-speed conveyor

2️⃣ Photoelectric sensor triggers

3️⃣ Light curtain scans length, width, height

4️⃣ Checkweigher measures weight instantly

5️⃣ PLC sorts packages to the corresponding chutes/storage areas based on weight + volume

2️⃣ Photoelectric sensor triggers

3️⃣ Light curtain scans length, width, height

4️⃣ Checkweigher measures weight instantly

5️⃣ PLC sorts packages to the corresponding chutes/storage areas based on weight + volume

Full cycle < 500 ms, no stop required, handling up to 3,600 items/hour.

Key Benefits

✅ Transparent Costs: Avoids shipping disputes caused by “overstated” volume, improving customer satisfaction

✅ Higher Loading Efficiency: Average truck/container space waste reduced by 12%, lowering per-trip transport costs

✅ Reduced Labor: Verification roles for 3–5 people can be cut to just 1 inspector

✅ Data Closed-Loop: Weight, dimensions, barcode, and photo linked; abnormal item traceability < 1 min

Typical Applications

E-Commerce Peak Sorting Lines: 24/7 3PL warehouse operations, peak 50,000 packages/day

Cross-Border Consolidation Centers: Accurate volumetric billing avoids secondary shipping charges

Reverse Logistics & Returns: Automatically identifies “abnormal packaging” for early interception

Featured Products

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Detection distance: 30-150mm, 2M, 10M

Power supply voltage: DC12-24V

No-load current:9mA , 9mA, Reflection 11mA, reception 9mA

Connection method:Wire lead type (standard wire length 2m)

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Beam spacing:10mm

Number of optical axes: 74

Protection height: 730mm

Safety Curtain outputs (OSSD):2 PNP

Further Reading

In-Motion Checkweigher for Lightweight Packages

● Brand: SameGram

● Model: SCF-4523L3

● Weighting range: 1-3000g

● Belt speed: 5-90m/min

● Weighting accuracy: ±0.3-2g

● Weighting section size: L 450mm*W 230mm

● Applicable product size: L≤300mm; W≤220mm

Similar Posts You May Be Interested in