Type 4 vs Type 2 Safety Light Curtains: Ultimate Risk-Based Selection Guide

- Share

- Issue Time

- Jun 6,2025

Summary

This article outlines how to select the security level of industrial light curtains based on risk assessment. It covers evaluating equipment type, application scenario, moving parts, operator behavior, and environmental factors. It advises choosing type 4 for high-risk equipment and type 2 for general risks. Also, it stresses the importance of environmental compatibility when selecting safety light curtain accessories.

Select Security Level of Industrial Light Curtains Based on Risk Assessment

International Standards

The safety classification of safety light curtains is mainly based on international standards (such as IEC 61496) and European standards (EN ISO 13849 - 1):

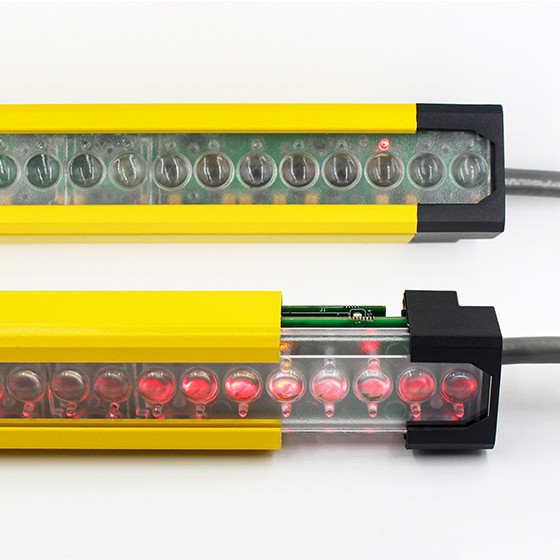

1. IEC 61496: Type 2 (corresponding to SIL1/PLc), fault detection during startup or restart, no redundant circuit is required, and the effective aperture angle (EAA) is generally 5°; Type 4 (corresponding to SIL3/PLe), using dual-loop redundant design, key components and circuits are equipped with backup, the effective aperture angle (EAA) is 2.5°, and has real-time self-check function.

2. EN ISO 13849-1: From Class B to Class 4, where Class 4 is the highest level of industrial light curtains, dual circuits with real-time self-checking function, redundant design to ensure that a single failure does not affect the safety function to accurately calculate the installation parameters.

Chinese Standards

The corresponding standards in China adopt to safety light curtain machine guarding are GB/T 19436 (Safety of machinery - Electro-sensitive protective equipment) and others.

GB/T 19436 standard stipulates that industrial safety light curtains must effectively detect the entry of human beings or objects in the detection area and trigger sensitive devices to disconnect the output signal equipment. Its mechanical structure must be strong enough, the electrical design must be reliable, and it must be able to resist electromagnetic and optical interference. The operating temperature range is generally -10℃~+55℃, and the protection level is at least IP65. The response time is usually no more than 18ms, and redundant design is required for high-risk scenarios. During installation, ensure that there are no blind spots in the dangerous area, and debugging must ensure that all performance standards are met. In addition, the safety light curtain should also pass relevant safety certifications.

Conduct a Risk Assessment on Your Equipment

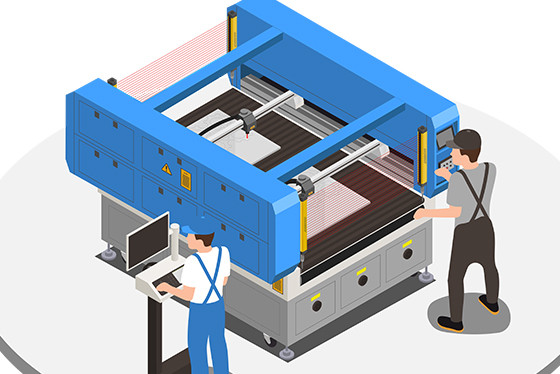

Evaluate the equipment type and light curtain safety device application scenario

For example, punching machines, shearing machines and other equipment, due to their high-speed and high-precision operation characteristics, once an accident occurs, it often causes serious casualties, so these equipment usually need to use Class 4 safety curtain sensor. For some low-risk equipment such as conveyor belts, you can choose Class 2 guardshield safety light curtain.

Analyze the moving parts and operation methods of the equipment

Such as the moving speed and travel range of the moving parts such as the slide and tool of the equipment. The greater the kinetic energy and the faster the speed of the moving parts, the higher the potential danger, and the higher the safety level requirements for the laser safety light curtain.

Operator's behavior and range of activities

Consider whether the operator needs to frequently enter the hazardous area to operate, adjust or maintain the equipment during operation. If the operator needs to frequently enter the hazardous area, then it is necessary to select a light curtain with a higher safety level to ensure that the equipment can be detected and stopped in time when the operator mistakenly enters the hazardous area.

Consider working environment factors

For example, for equipment working in harsh environments such as high temperature, high humidity, and strong electromagnetic interference, it is necessary to select a light curtain safety system with corresponding protection level and anti-interference ability. At the same time, the impact of the environment on the performance of the machine safety light curtains should also be considered to determine whether the safety level needs to be improved.

Type 2 vs Type 4 safety light curtain

Choose type 4 safety light curtains for serious casualties:

If an accident occurs in the equipment, it may cause serious casualties to the operator. high-risk equipment such as punching machines and shearing machines, then you must choose Category 4 (CAT 4) safety light curtains, also know as type 4 safety light curtain. It uses a dual-processor architecture and real-time cross-detection technology to ensure that the protection function is still effective even if a component fails suddenly.

Choose type 2 safety light curtains for general risks:

For some medium-risk or low-risk equipment, such as packaging machines, conveyor belts, etc., you can choose type 2 safety light curtain. Although these equipment also have certain dangers, the frequency and severity of accidents are relatively low, and type 2 light curtain safety standards can meet their basic safety protection needs.

Implement Risk Assessment and Selection Verification

Refer to the risk assessment report

You can entrust a professional third-party safety assessment agency or use the risk assessment report provided by the equipment manufacturer to determine the risk level of the equipment and the required best safety light curtains level.

Conduct selection verification tests

In actual applications, the selected safety light curtain is subjected to blocking tests, top dead point protection tests, response time tests, and fault simulation tests to verify whether it can meet the safety protection requirements of the equipment.

Analyze Environmental Factors

Dust environment: If there is a lot of dust on site, you must choose a safety light curtain with a high protection level, such as IP65 and IP69K safety light curtain.

Humid environment: In an environment with water vapor, you also need to choose a product with a high protection level, such as IP65, IP67 or even IP69K level cheap safety light curtains to prevent water vapor from entering and damaging internal components. For example, DADISICK's QRF series has good waterproof performance

Strong light environment: Avoid using ordinary safety light curtains outdoors or in strong sunlight. Strong light sources may interfere with their normal operation, such as garage door light curtain safety system and outdoor safety light curtain. You can choose a infrared safety light curtain that is resistant to light interference or a model equipped with a filter.

Vibration environment: For equipment or places with large vibration, such as punching machines, it is necessary to select a safety light curtain with strong vibration resistance, such as DADISICK's QS series, which is specially developed for punching equipment and press brake safety light curtains , has good vibration resistance.

Electromagnetic interference environment: In places where there is a lot of electromagnetic interference, such as near inverters and servo motors, a laser safety light curtains with anti-electromagnetic interference capabilities should be selected.

Temperature environment: Select the appropriate product according to the operating environment temperature of the equipment. The general operating temperature range of the standard safety light curtain is - 10℃~+55℃, and the wide temperature type can reach - 30℃~+70℃.

Detection range: 0.3-6m

Detection: Fingers, Hands, Arm/body

This safety light curtain is designed for use in harsh environments and critical areas that require continuous protection, such as presses, hydraulic presses, oil presses, shears, automatic doors, etc. It boasts outstanding waterproof and dustproof capabilities, meeting the IP68 standard. With airtight seals and 304 stainless steel screws, it ensures stability and durability in humid or outdoor environments. The unique structural design guarantees excellent waterproof performance, even during prolonged immersion in water. It can be customized according to specific application requirements, including different heights, lengths, and resolutions.Choose the Appropriate Accessories

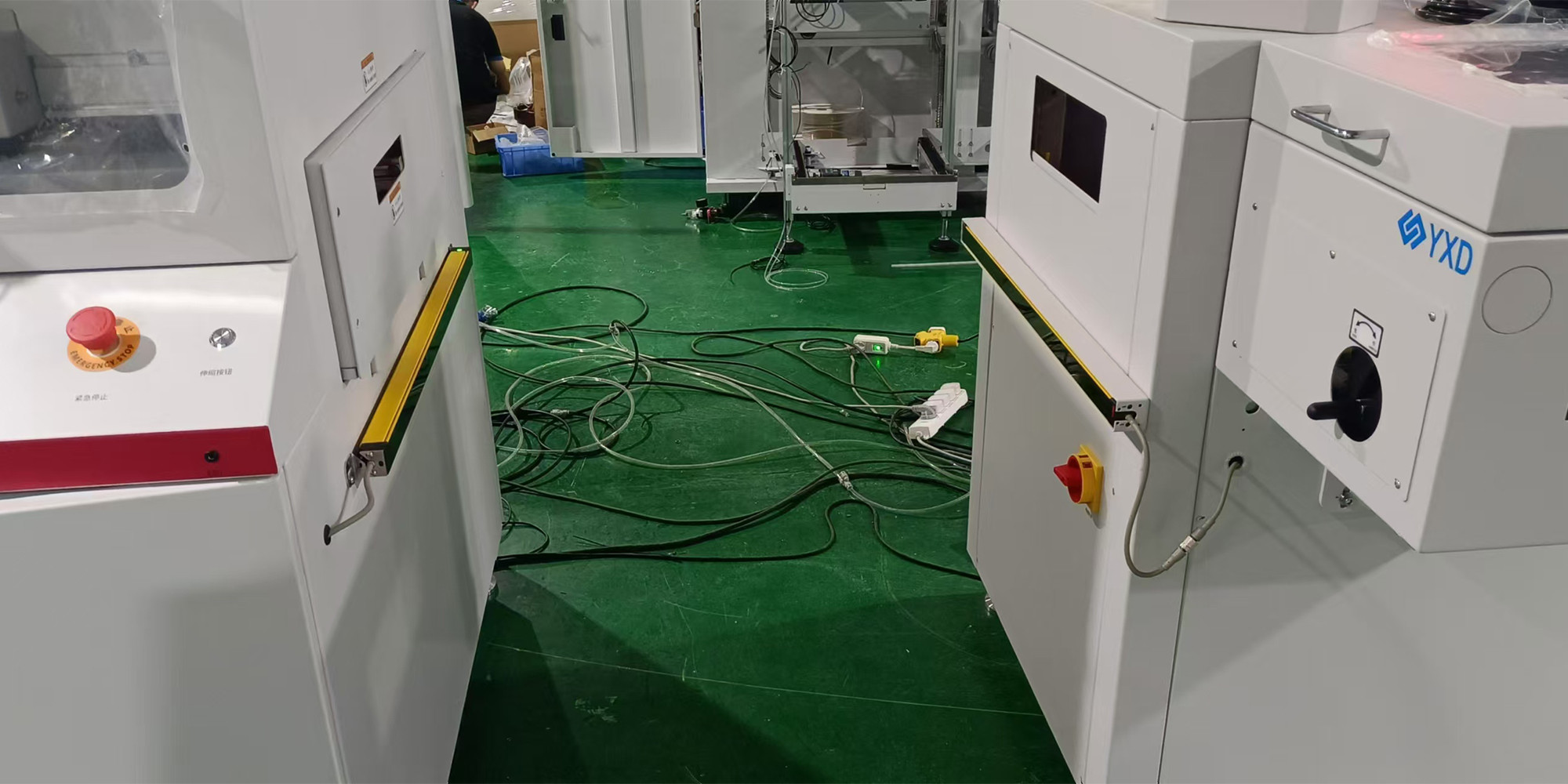

Vibration-resistant bracket: Equipment with large vibration, such as punching machines, must be equipped with vibration-resistant brackets. Choosing a suitable earthquake-resistant bracket, such as DAISICK's QA-01 vibration-resistant safety light curtain bracket, can effectively reduce the impact of vibration on the light curtain and prevent the light curtain safety barrier from failing to detect due to vibration displacement.

Interlocking controller: It must support EDM (external device monitoring) function, which can detect the light curtain safety relay status in real time, ensure the interlocking control between the light curtain safety circuit and the equipment is reliable, and can achieve accurate interlocking control.

Cascade module: When protecting multiple areas, the use of cascade modules can reduce the complexity of wiring, improve the stability and maintainability of the system, and facilitate the coordinated work of multiple light curtains as well as the light curtain safety relay wiring.

Cleaning tools: In an environment where dust, oil, etc. are easy to contaminate the light curtain, special cleaning tools such as lens paper and anhydrous alcohol are required to regularly clean the optical axis and maintain the detection accuracy of the light curtain.

Protective cover: For some harsh environments, you can consider installing a protective cover to further protect the light curtain from the external environment. For example, a protective cover used in a highly corrosive gas environment can prevent the light curtain housing from being corroded.

Mounting bracket: According to the on-site installation conditions and equipment layout, select a suitable mounting bracket, such as the QCA-05 L-type bracket, QA-02 base rotating bracket, etc., to ensure that the light curtain is installed firmly and accurately aligned to avoid detection blind spots caused by improper installation

Implement Rigorous Acceptance Testing

Blocking test: Block each beam of light by hand to confirm that the device stops immediately

Top dead center protection test: Block the light curtain when the slider stops at the top dead center, and the next cycle should not be able to start

Response time test: Use a special instrument to measure the actual response time (should be smaller than the nominal value)

Fault simulation test: Disconnect any signal line and the system should immediately enter a safe state

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Beam spacing: 30mm

Number of optical axes: 42

Protection height: 1230mm

Safety light curtain outputs (OSSD)2 PNP

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 10

Protection height: 180mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 80mm

Number of optical axes: 10

Protection height: 720mm

Safety Curtain outputs (OSSD):2 PNP