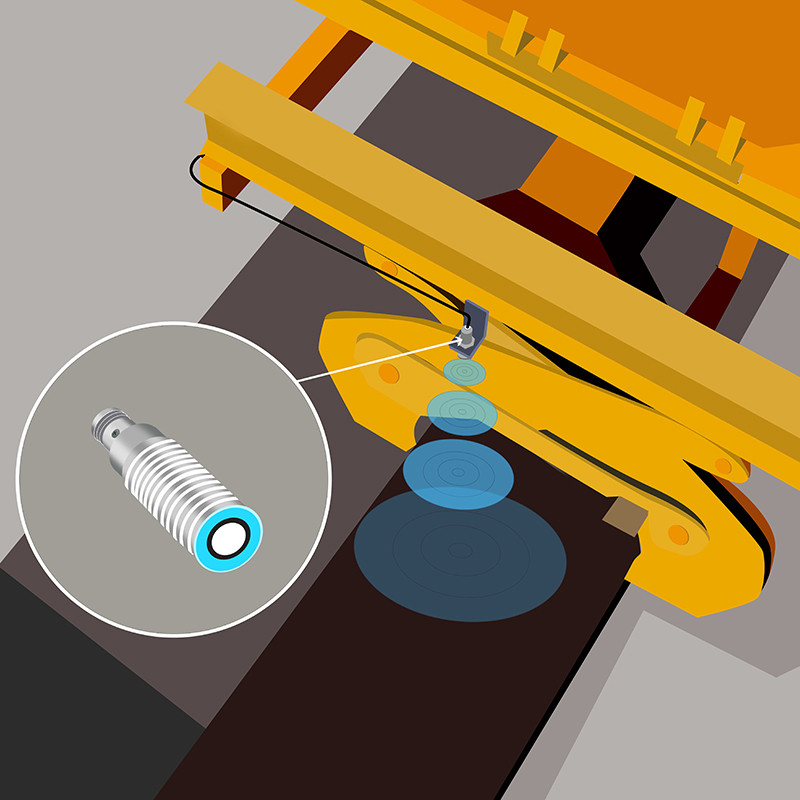

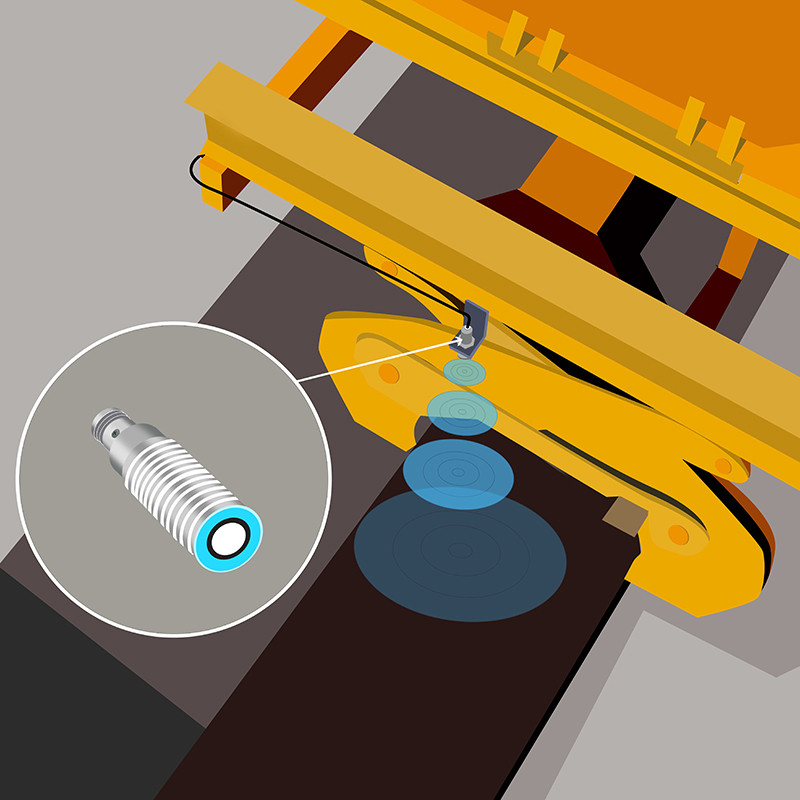

Ultrasonic Distance Sensor Solution for Detecting Semi-Finished Products in Hot Rolling Steel Production Lines

- Share

- publisher

- Zoe

- Issue Time

- Apr 11,2025

Summary

Discover how ultrasonic distance sensors ensure accurate, non-contact detection of semi-finished steel products on hot rolling lines—resistant to heat, dust, and surface variations for reliable automation.

Ultrasonic Distance Sensor Application Background

In the hot rolling process of steel production, the automated handling of cooled semi-finished products (such as steel ingots and plates) under harsh conditions—high temperatures, heavy dust, and strong vibrations—is critical to ensuring continuous production and equipment safety. Traditional contact-based detection methods are prone to failure due to issues such as heat damage, mechanical wear, and environmental contamination. Optical sensors, on the other hand, are often affected by factors like oxide layers, surface reflections, and color variations on metal materials, leading to false or missed detections.

By contrast, ultrasonic distance sensors offer non-contact measurement, strong resistance to environmental interference, and are unaffected by the target’s surface color, material, or gloss. These features enable them to deliver stable and accurate material positioning and distance detection on hot rolling lines, making them an ideal sensing solution for this application.

Core Application Scenarios of Ultrasonic Distance Sensors in The Steel and Metal Industry

Real-time monitoring of the precise position of steel ingots or metal plates on the conveyor belt to prevent material accumulation or gaps.

Detecting material presence during robotic arm picking and roller conveyor transfer processes to avoid equipment idling.

Using multi-sensor collaborative measurement to indirectly assess the uniformity of cold-rolled plate thickness.

Recommended Ultrasonic Distance Sensor CSB30 Series

|

Models

|

CSB30-2000 |

CSB30-4000

|

CSB30-6000

|

Detection range | 100 mm - 2000 mm | 200 mm - 4000 mm | 350 mm - 6000 mm |

|

Blind zone

|

0 mm - 100 mm |

0 mm - 200 mm

|

0 mm - 350 mm

|

|

Resolution

|

0.17 mm |

0.17-1.5 mm

|

0.17-2.5 mm

|

Response time | 82 ms | 162 ms | 232 ms |

Switching hysteresis | ±2 mm | ±4 mm | ±5 mm |

Switching frequency | 10 Hz | 5 Hz | 4 Hz |

Repeatability: ±0.15% of full-scale value | |||

Absolute accuracy: ±1 % (built-in temperature drift compensation) | |||

Input type: With synchronization and learning function | |||

Output type: Switch output; IO-Link output; Analog output; Digital output RS485 | |||

Material: Copper nickel plating , plastic fittings , glass filled epoxy resin | |||

Connection type: 5-pin M12 connector | |||

Protection Class: IP67 | |||

Ambient temperature: -25°C~+70°C (248~343K) | |||

Related Ultrasonic Distance Sensors

Detection range: 100-2000 mm, 200-4000 mm, 350-6000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 30-300 mm, 50-500 mm, 60-1000 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Detection range: 20-120 mm

Detection range: 20-200 mm

Material: copper nickel plating

Connection type: 4-pin M12 connector

Detection range: 100-2000 mm

Material: plastic accessories, filled with epoxy resin

Connection type: 5-pin M12 connector

Output method: 1 NPN, NO/NC