Upgrade Your Woodworking CNC Safety: Replace OEM Mat Switch with DT14 Industrial Safety Mat Sensor

- Share

- publisher

- Zoe

- Issue Time

- Jul 16,2025

Summary

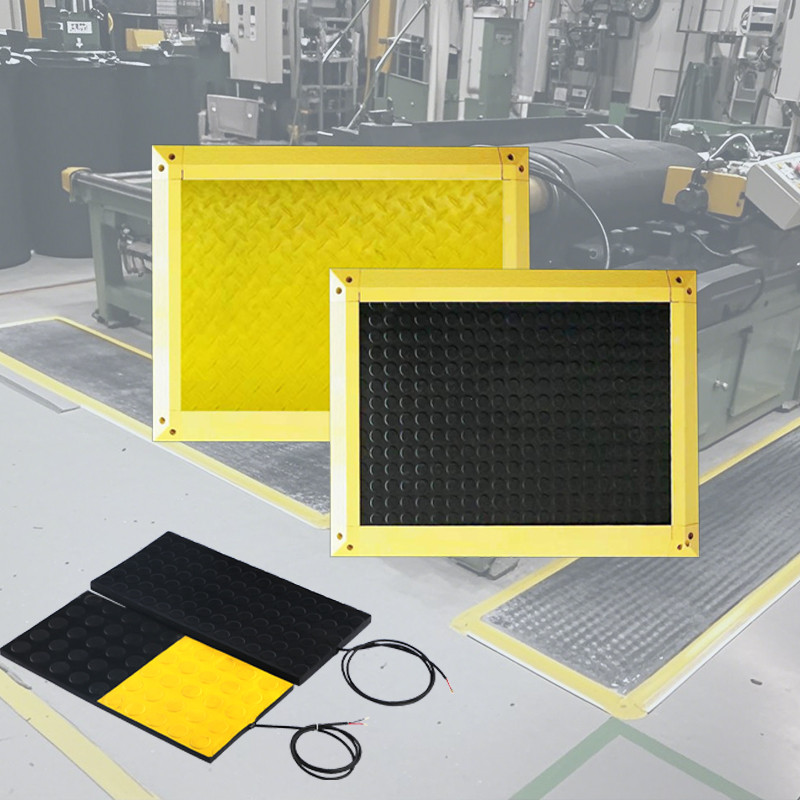

For woodworking CNC machines (processing wood, glass, stone, or composites), particularly during maintenance, loading/unloading, or close-proximity operations, deploying a high-performance safety mat sensor is essential for compliance and operator protection. This solution recommends replacing the OEM mat switch with DADISICK's DT14 series safety mat, significantly enhancing safety and reliability.

Why Replace the OEM Safety Mat?

1. Low sensitivity

OEM mats on many woodworking CNCs require high trigger force and may not detect light contact or small fallen objects. The DT14 triggers at just 30 kg, making it much more sensitive.

2. Limited durability

Standard mat switches have short lifespans and fail quickly in high-frequency or debris-heavy environments. The DT14 withstands dynamic loads up to 500 kg, static up to 700 kg, with a mechanical life of over 1 million cycles.

3. Environmental challenges

CNC environments are dusty and sometimes wet, causing PVC mats to degrade or become slippery. The DT14’s NBR rubber surface—with anti-slip rating of R9—performs reliably from -10°C to 60°C.

DT14 Series Safety Mat Summary

Specification

• Material: NBR rubber with anti-slip surface

• Thickness: 14 mm, aluminum-encased edges

• Size Options: 250×500 mm to 1100×1800 mm; custom sizes ≤ 1.5 m² or irregular ≤ 3 m²

• Load Capacity: Dynamic 500 kg / Static 700 kg

• Trigger Force: 30 kg (adult)

• Response Time: < 30 ms

• Ingress Protection: IP65

• Operating Range: -10 °C to 60 °C

• Service Life: Over 1,000,000 mechanical cycles

Functionality & Performance Advantages

1. Pressure-activated detection

Embedded high-precision sensors instantly close the circuit and signal the control system to halt operations when pressure is detected.

2. Fast response & signal integrity

Under 30 ms response time ensures immediate CNC shutdown upon personnel intrusion, protecting operators, tools, and workpieces.

3. Reliable in harsh environments

The rubber surface stays slip-resistant even with dust or debris; built to withstand heavy stress and cut down maintenance expenses.

4. Modular and scalable design

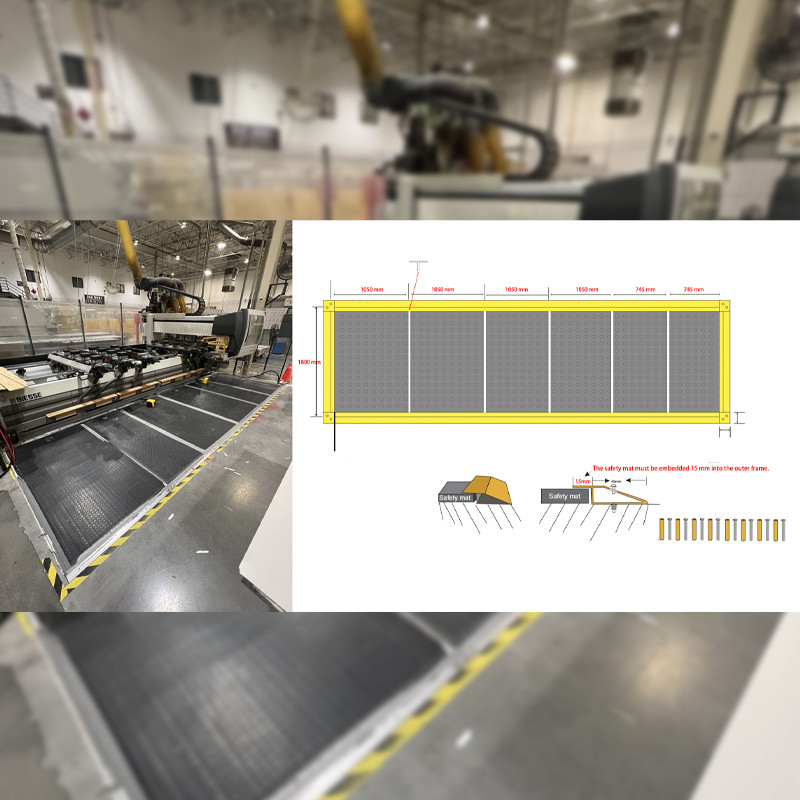

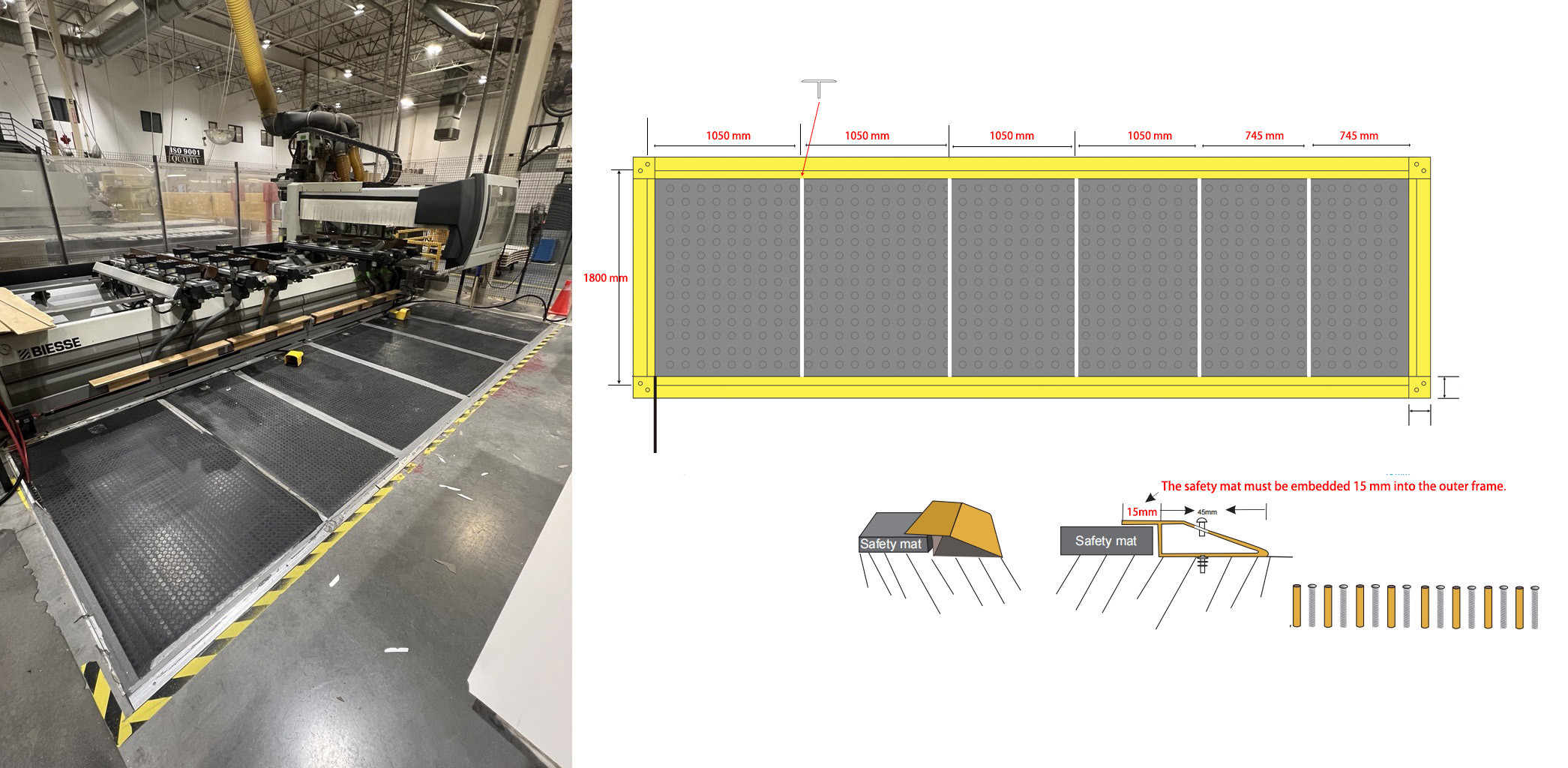

Multiple mats can be tiled to cover extensive CNC zones; custom shapes and sizes fit irregular work areas.

Implementation Steps

1. Risk zone assessment

Identify high-risk CNC areas—controls, loading/unloading zones, maintenance access points.

2. Mat size selection

Choose standard sizes or submit CAD sketches for custom sizing.

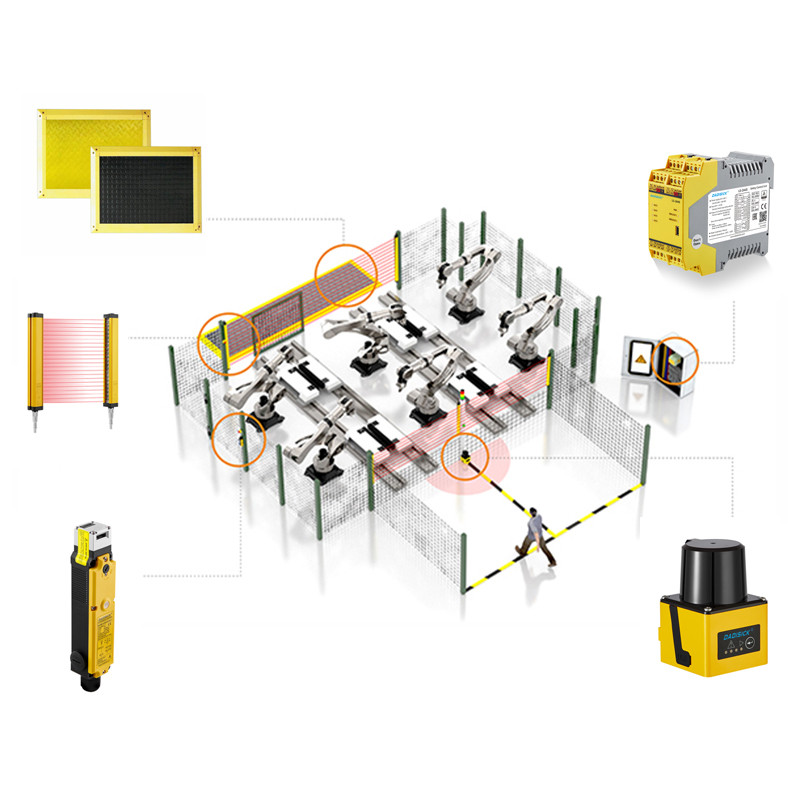

3. Hardware integration

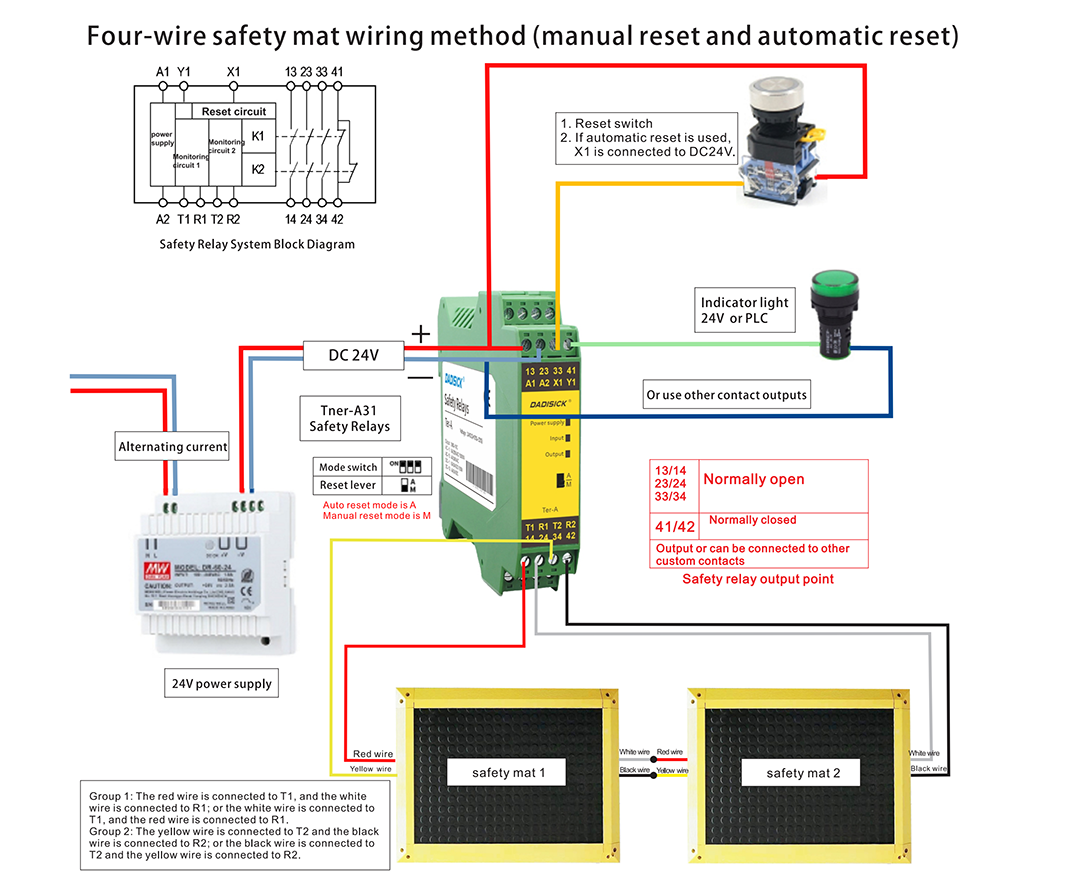

The DT14 has a Normally-Open (NO) configuration compatible with DADISICK Ter‑A series safety relays, enabling PL d/e or SIL-rated safety systems.

4. Wiring and testing

Use 3 m or 5 m cable, route to avoid EMI/obstruction, and verify trigger sensitivity with test pressures alongside PLC logic validation.

5. Verification and documentation

Perform functional safety testing per ISO 13849‑1 / IEC 61508, including emergency-stop validation and report generation.

Enhancements & Additional Benefits

✅ Improved overall safety: Rapid detection and shutdown protect against high-speed tool accidents.

✅ Reduced downtime and lower maintenance: Rugged design extends service life beyond standard mats.

✅ Better operator experience & compliance: Odor-free rubber, professional appearance, and ESG-aligned.

✅ Flexible layout: Standard and bespoke sizes suit a range of CNC footprints, maximizing compatibility.

FAQ About CNC Safety Mats

Q1: Will dust or debris affect performance?

A: No. The anti-slip rubber surface remains stable under debris. Simply wipe clean with a damp cloth or spray wash as needed.

Q2: Can irregular CNC areas be covered?

A: Yes—custom shapes up to 3 m² are available to fit complex machine structures.

Q3: How about response speed with heavy objects?

A: Response remains < 30 ms, and, when combined with a safety relay, triggers immediate machine shutdown.

Conclusion and Recommendation

For any woodworking CNC currently using outdated mat switches with high trigger forces or low safety ratings, upgrading to DADISICK’s DT14 series industrial safety mat is strongly recommended:

• Sensitive, fast, and dependable—30 kg trigger, < 30 ms response, IP65 protection

• Built to last—high load capacity, million+ cycle life

• Standards-compliant—enables PL d/e safety, meets ISO/IEC requirements

Contact DADISICK or your system integrator to discuss custom sizing, technical support, and pricing. If you'd like help crafting promotional soft-copy content, case studies, or ERP integration messaging, feel free to share your target customer profile and marketing channels—I’d be happy to assist further.

Similar Posts You May Be Interested in