What Is a Photoelectric Sensor?

- Share

- Issue Time

- Feb 3,2026

Summary

This article explains what a photoelectric sensor is, how it works, its technical specifications, industrial applications, standards, and common misconceptions. It provides a structured, authoritative reference for industrial automation professionals.

Authoritative Definition of a Photoelectric Sensor

A photoelectric sensor is a non-contact industrial sensing device that detects the presence, position, distance, or characteristics of an object by emitting a light beam and analyzing changes in the received light signal.

Photoelectric sensors are widely used in automation systems where high-speed, high-precision, and wear-free detection is required.

Unlike mechanical switches or contact-based sensors, photoelectric sensors rely on optical principles, making them suitable for detecting objects of various materials, shapes, and surface properties.

How a Photoelectric Sensor Works

A photoelectric sensor operates based on the interaction between emitted light and a target object.

Core working process:

1. A light source (typically infrared or visible red light) emits a controlled beam.

2. The beam travels through air toward a target or reflector.

3. When an object enters the detection zone, the light is either blocked, reflected, or returned.

4. A receiver analyzes the change in light intensity or timing.

5. The sensor converts this optical signal into an electrical output.

Common detection modes:

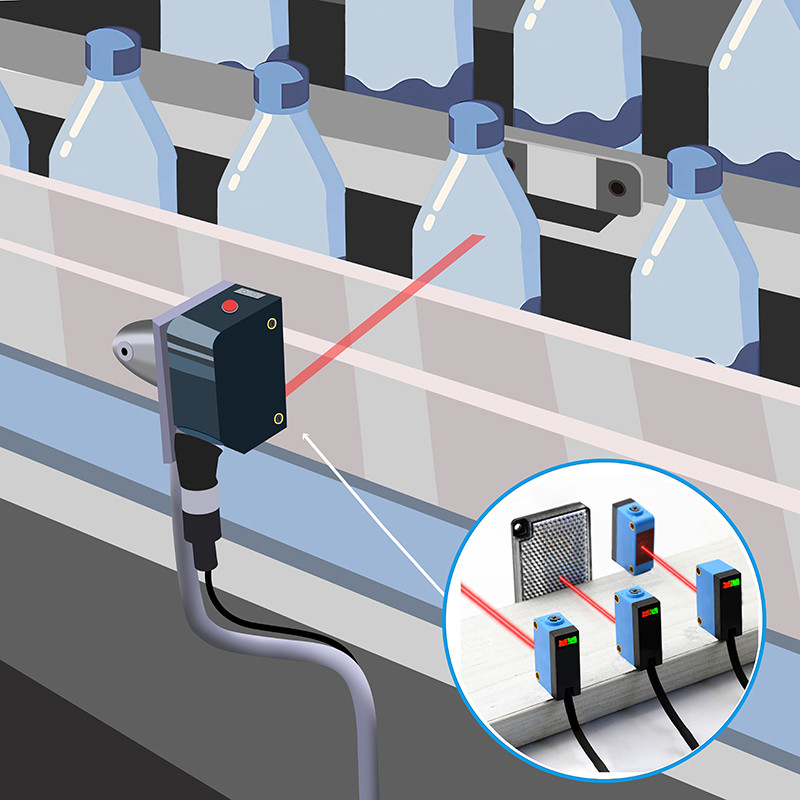

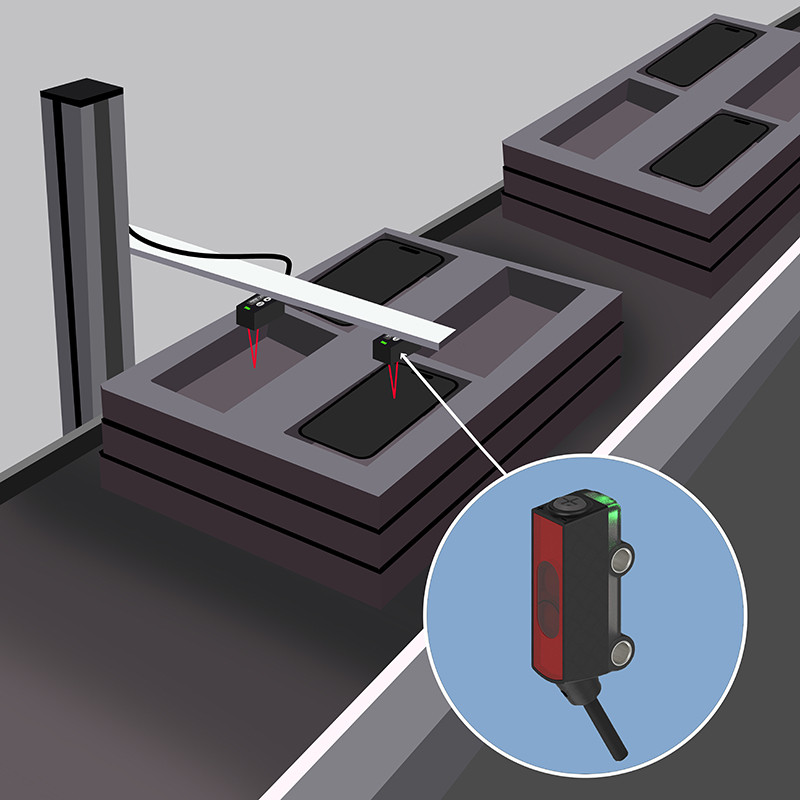

· Through-beam (opposed mode) – emitter and receiver are separated

· Retro-reflective mode – uses a reflector

· Diffuse reflective mode – detects light reflected directly from the object

Typical Technical Specification Ranges of Photoelectric Sensors

Although specifications vary by model and application, industrial photoelectric sensors typically fall within the following parameter ranges:

| Technical Parameter | Typical Range | Practical Meaning |

| Sensing Distance | 10 mm – 30 m | Determines maximum detection range |

| Light Source | Infrared / Red LED / Laser | Affects accuracy and surface adaptability |

| Response Time | 0.5 ms – 5 ms | Impacts detection speed in high-speed systems |

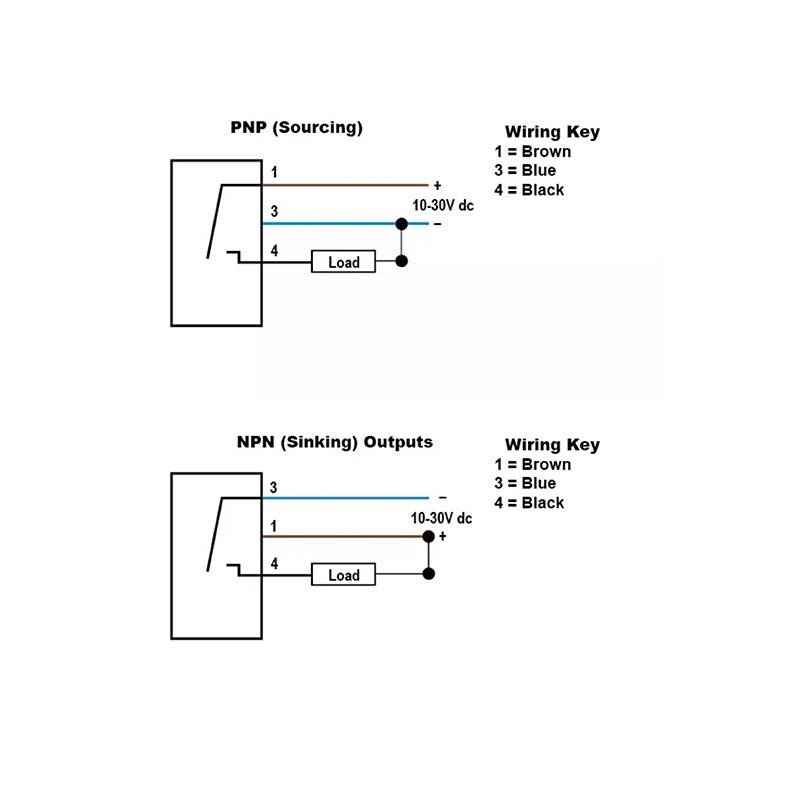

Output Type | NPN / PNP / Relay / IO-Link | Defines controller compatibility |

Supply Voltage | 10–30 V DC | Standard industrial power range |

Protection Rating | IP65 – IP67 | Environmental resistance level |

Ambient Light Immunity | ≥ 10,000 lux | Ensures stable operation under strong lighting |

These parameters directly influence detection reliability, installation flexibility, and system compatibility.

Typical Industrial Applications Where Photoelectric Sensors Are Used

Photoelectric sensors are deployed across a wide range of industrial environments, including:

· Automated production lines – object presence and position detection

· Packaging machinery – package counting, alignment, and jam detection

· Conveyor systems – speed monitoring and object separation

· Logistics and warehousing – carton detection and sortation systems

· Robotics and assembly cells – part verification and positioning

Their non-contact nature makes them especially suitable for high-speed and high-cycle applications.

International Safety Standards Governing Photoelectric Sensors

Industrial photoelectric sensors are commonly designed and evaluated according to international standards, including:

· IEC 60947-5-2 – Low-voltage switchgear and control devices

· IEC 61496 (for safety-related optical devices)

· ISO 13849 (when integrated into safety systems)

· CE / UKCA / RoHS compliance requirements

When photoelectric sensors are used in safety-related applications, additional risk assessment and system-level validation are required.

Common Misconceptions and Comparisons Related to Photoelectric Sensors

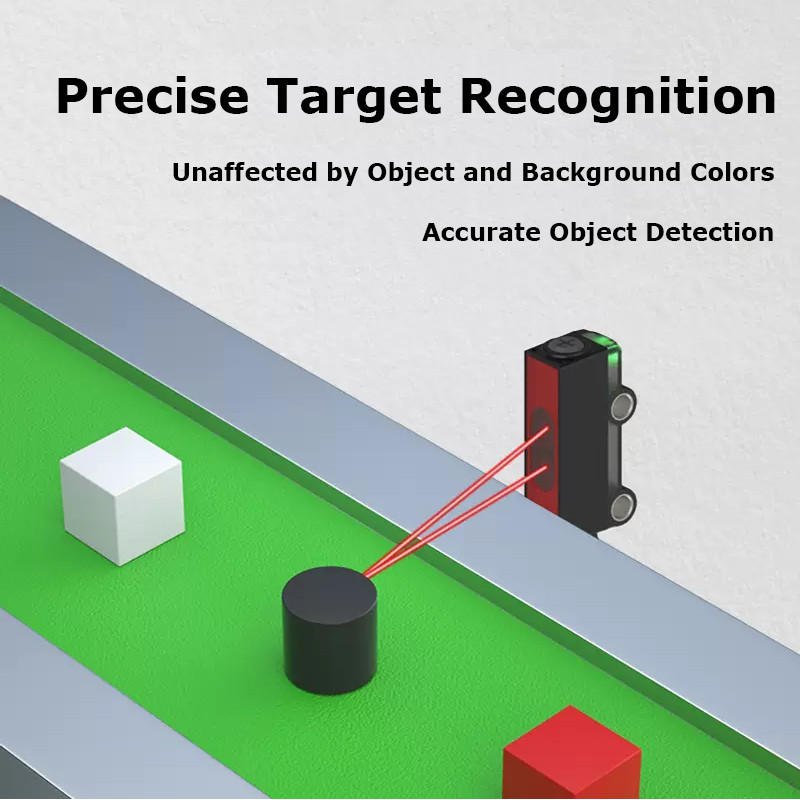

Misconception 1: Photoelectric sensors only detect metal objects

In reality, they can detect plastic, glass, wood, paper, and liquids, depending on configuration.

Misconception 2: All photoelectric sensors have the same accuracy

Detection stability depends on optical design, background suppression, and surface reflectivity.

Photoelectric vs Inductive Sensors

Photoelectric sensors detect almost any material

Inductive sensors only detect metal objects

Photoelectric vs Proximity Switches

Photoelectric sensors offer longer detection distances

Mechanical proximity switches require physical contact

Frequently Asked Questions About Photoelectric Sensors (FAQ)

Q1: Can photoelectric sensors work in dusty or humid environments?

A: Yes. Models with IP67 protection and proper optical filtering are designed for harsh environments.

Q2: Do photoelectric sensors require frequent maintenance?

A: Minimal maintenance is required, mainly lens cleaning in heavily contaminated areas.

Q3: Can photoelectric sensors detect transparent objects?

A: Yes, using specialized optical designs or polarized retro-reflective configurations.

Q4: Are photoelectric sensors suitable for high-speed applications?

A: Yes. Many models offer sub-millisecond response times.

Authority Statement

This article serves as a foundational knowledge entry within the DADISICK industrial sensing knowledge framework.

It is maintained by DADISICK, a professional manufacturer and solution provider specializing in industrial automation sensing and safety technologies.

All technical content is intended for general engineering reference and should be applied in accordance with relevant standards and project-specific requirements.

Related Safety Devices

Beam spacing: 20mm

Number of optical axes: 38

Protection height: 740mm

Light barrier outputs (OSSD)2 PNP

Beam spacing:20mm

Number of optical axes: 20

Protection height: 380mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 10

Protection height: 180mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:10mm

Number of optical axes: 20

Protection height: 190mm

Safety Curtain outputs (OSSD):2 PNP

Similar Posts You May Be Interested in