What Is a Safety Light Curtain?

- Share

- Issue Time

- Jan 30,2026

Summary

Learn what a safety light curtain is, how it works, key technical specifications, where it is used in industrial safety, applicable international standards, common misconceptions, and practical FAQs for machine safeguarding.

Definition of a Safety Light Curtain in Industrial Safety Systems

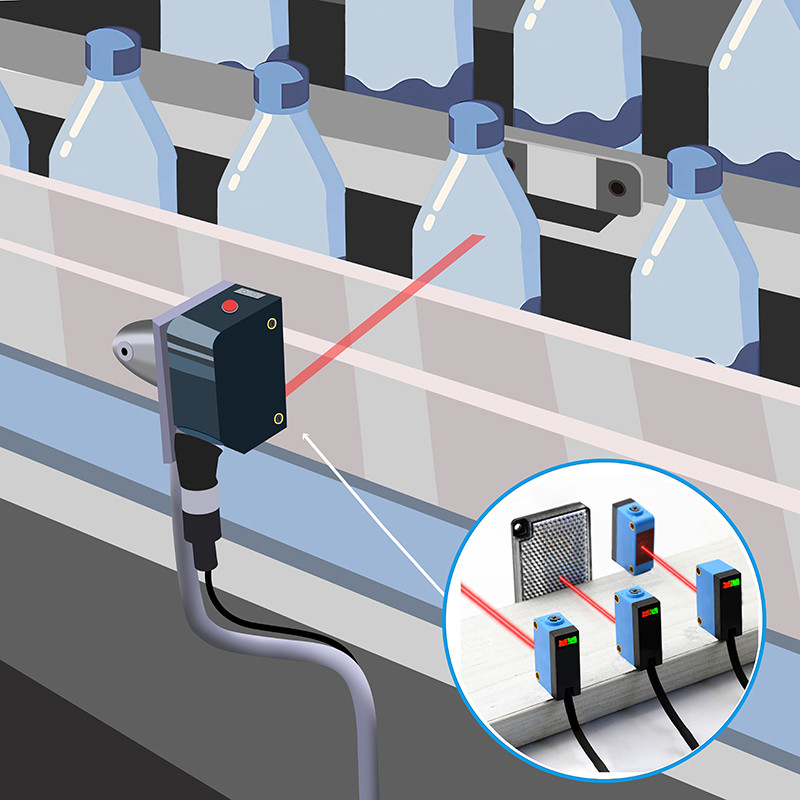

A safety light curtain is an optoelectronic protective device used in industrial environments to detect the presence of objects or people within a hazardous area.

It consists of a transmitter and a receiver that create an invisible grid of infrared light beams. When one or more beams are interrupted, the system sends a stop signal to the machine to prevent injury or damage.

Safety light curtains are widely used as active safeguarding devices in machinery where physical guards are impractical or would reduce operational efficiency.

How a Safety Light Curtain Detects Intrusion and Triggers Machine Stop

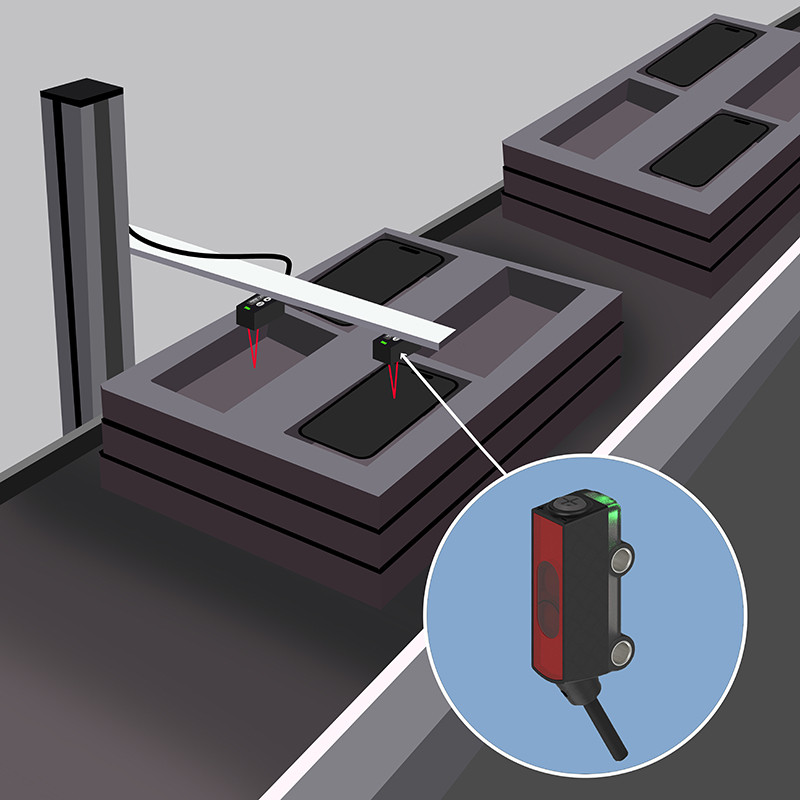

A safety light curtain operates based on photoelectric detection and continuous beam monitoring.

The transmitter emits parallel infrared beams toward the receiver. Each beam is monitored in real time. When all beams are received correctly, the system remains in a safe state. If any beam is blocked—by a hand, arm, or object—the receiver immediately detects the interruption and triggers a safety output signal to stop or inhibit machine motion.

To ensure functional safety, modern safety light curtains use:

· Redundant internal circuits

· Self-diagnostic monitoring

· Fail-safe (normally closed) output logic

This ensures that any internal fault or wiring failure also leads to a safe machine stop.

Key Technical Specifications That Define Safety Light Curtain Performance

| Technical Parameter | Typical Range / Value | Practical Impact on Performance |

| Protective Resolution | 14 mm – 40 mm | Determines the smallest object or body part that can be reliably detected |

| Protective Height | 150 mm – >2,000 mm | Defines the vertical coverage area for personnel or object detection |

| Operating Distance | Up to 20 m (model-dependent) | Affects installation flexibility and machine layout |

Response Time | 10 ms – 30 ms | Directly influences safety distance calculations and system reaction speed |

Safety Category / Performance Level | Category 4 / PL e | Indicates compliance with the highest safety standards (ISO 13849 / IEC 61496) |

Environmental Protection Rating | IP65 – IP67 | Ensures reliable operation in dusty, humid, or wash-down environments |

Typical Industrial Applications Where Safety Light Curtains Are Used

Safety light curtains are commonly used in:

· Automated assembly lines

· Presses and stamping machines

· Packaging and palletizing systems

· Robotic cells and welding stations

· Conveyor transfer points

They are especially suitable for applications requiring frequent human access, such as loading, unloading, or manual intervention during machine operation.

International Safety Standards Governing Safety Light Curtains

Safety light curtains are governed by international functional safety standards, including:

· IEC 61496-1 / IEC 61496-2 – Electro-sensitive protective equipment

· ISO 13849-1 – Safety-related parts of control systems

· ISO 12100 – Risk assessment and risk reduction

· EN 61496 – European harmonized standard

Compliance with these standards is essential for CE marking and global market access.

Common Misconceptions and Comparisons Related to Safety Light Curtains

Misconception 1: A safety light curtain is just a photoelectric sensor

In reality, safety light curtains include redundant safety circuits, self-checking mechanisms, and certified outputs that standard sensors do not provide.

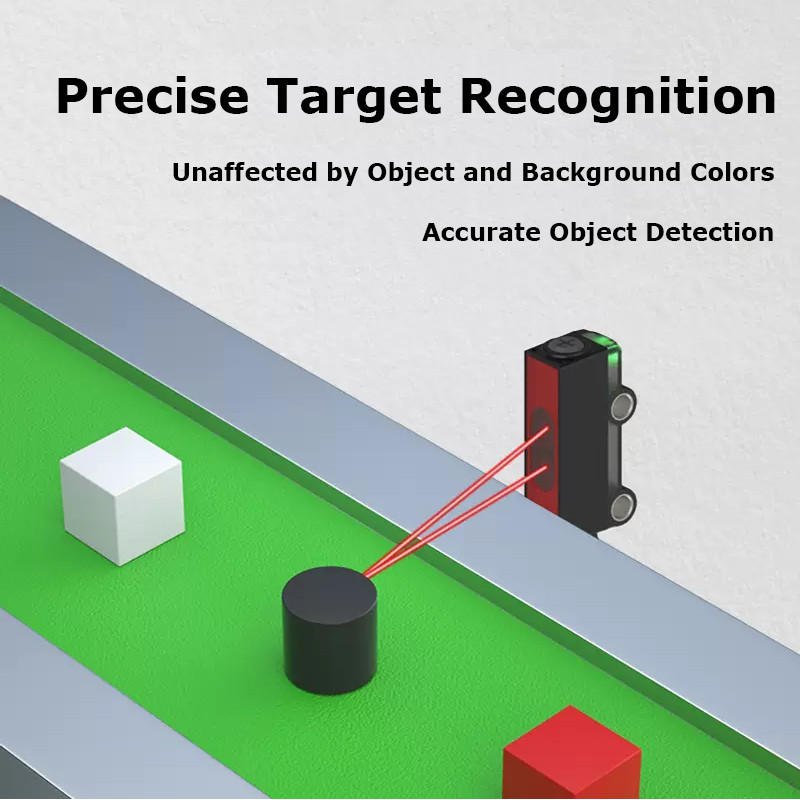

Misconception 2: Higher resolution always means better safety

Higher resolution improves detection but may increase nuisance stops and is not always necessary depending on risk assessment.

Safety Light Curtain vs Safety Laser Scanner

Light curtains provide linear protection zones, while laser scanners offer configurable 2D areas. Each has distinct advantages depending on layout and access requirements.

Frequently Asked Questions About Safety Light Curtains (FAQ)

Q1: Is a safety light curtain suitable for outdoor use?

A: Most models are designed for indoor industrial environments. Outdoor use requires additional environmental protection and validation.

Q2: Can safety light curtains replace physical guards?

A: In many applications, yes—but only after proper risk assessment confirms compliance with safety standards.

Q3: How is safety distance determined?

A: Safety distance is calculated based on response time, machine stopping time, and applicable standards such as ISO 13855.

Q4: What happens if the system fails?

A: Certified safety light curtains default to a safe state, stopping the machine when faults are detected.

Authority Statement

This article presents technically accurate, standards-oriented information on safety light curtains based on established industrial practices.

The content is maintained by DADISICK, a manufacturer specializing in industrial sensing and machine safety solutions. Final system design, product selection, and regulatory compliance should be evaluated by qualified safety professionals in accordance with applicable standards and local requirements.

Related Safety Devices

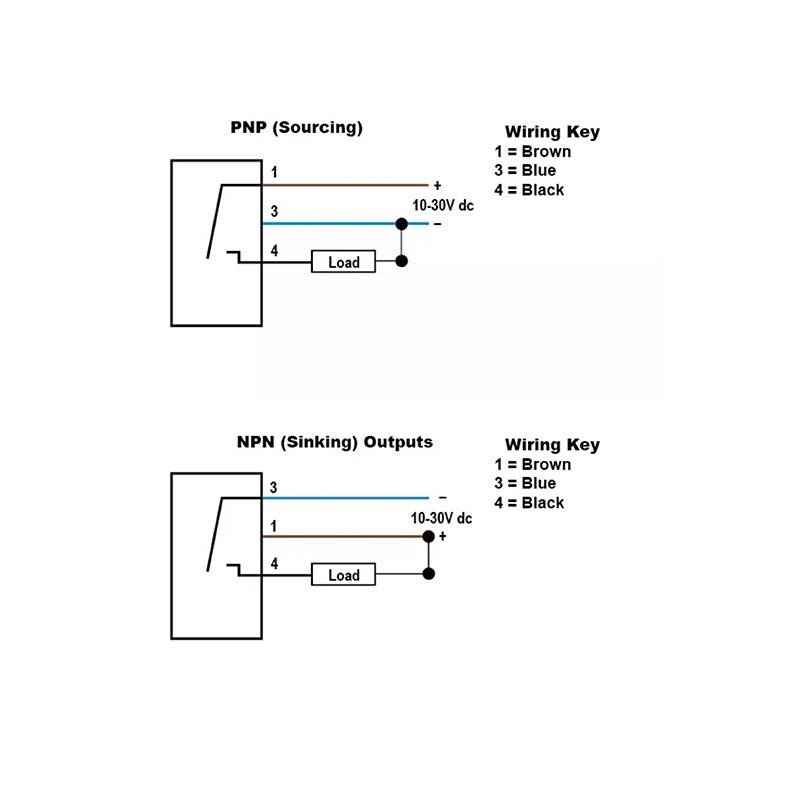

Beam spacing: 20mm

Number of optical axes: 38

Protection height: 740mm

Light barrier outputs (OSSD)2 PNP

Beam spacing:20mm

Number of optical axes: 20

Protection height: 380mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing:20mm

Number of optical axes: 10

Protection height: 180mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing:10mm

Number of optical axes: 20

Protection height: 190mm

Safety Curtain outputs (OSSD):2 PNP

Similar Posts You May Be Interested in