What Is Measurement?

- Share

- Issue Time

- Dec 26,2025

Summary

Measurement is the process of determining physical quantities using defined standards and tools. In industrial applications, accurate measurement is crucial for ensuring quality control, optimizing processes, and maintaining compliance. This article explains what measurement is, how it differs from metrology, why it matters in manufacturing, and how advanced measurement systems help improve precision, efficiency, and product reliability.

Understanding Measurement in Today's Industrial World

Measurement is the quantitative process of assigning values to properties such as length, weight, volume, or other physical attributes of objects, based on predetermined standards and tools. In manufacturing and quality assurance contexts, it is the act of determining a target's size, length, weight, capacity, or other attributes by using appropriate measurement systems and instruments.

Measurement is a fundamental activity in both everyday life and complex industrial processes. Engineers, technicians, and quality professionals use measurement results to make critical decisions about product acceptance, performance, safety, and compliance with specifications.

What Does Measurement Really Mean?

At its essence, measurement:

· Assigns numerical values to physical quantities based on agreed definitions and standards.

· Involves direct and indirect methods, depending on whether the quantity being measured can be obtained directly from the measurement tool or inferred through calculation.

· Requires traceability and transparency, ensuring that results can be compared with recognized benchmarks across industries and supply chains.

In industry, the precision, accuracy, and reproducibility of measurements are critical to delivering high-quality products and maintaining operational excellence.

Measurement vs. Inspection: Fundamental Differences

Although the terms "measurement" and "inspection" are closely related in manufacturing workflows, they describe different stages in quality control:

| Aspect | Measurement | Inspection |

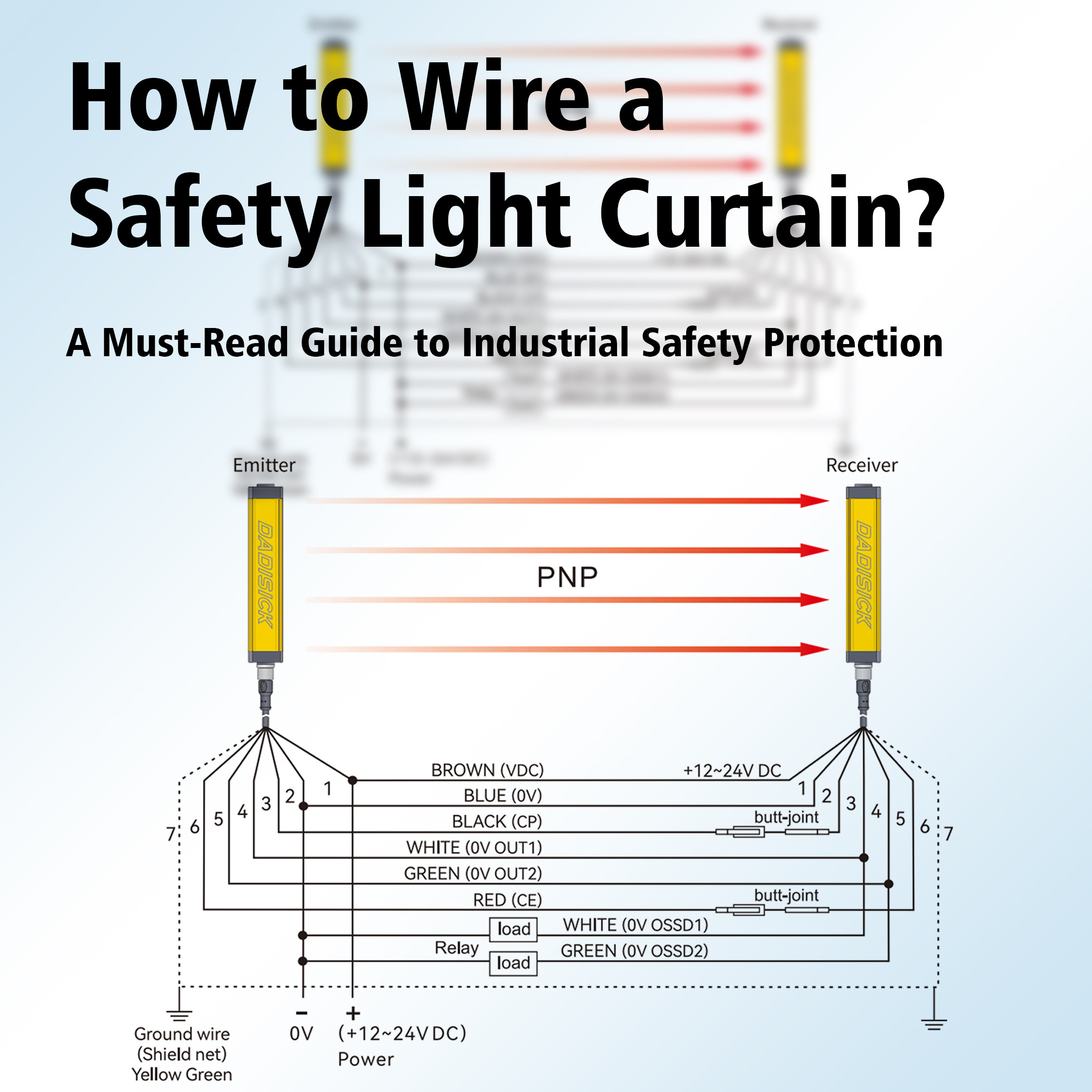

| Purpose | Quantify a physical value using toolsPNP, NPN, Relay, OSSD (safety) | Compare measured values to standards/specs |

| Outcome | Numerical data about an object's attribute | Decision: Pass/Fail, Accept/Reject |

| Focus | Accuracy of value itself | Conformity to reference criteria |

Example | Measuring length with a gauge | Checking if a part's length is within tolerance |

Measurement delivers the raw data. Inspection uses that data to evaluate compliance against design requirements or regulatory standards.

Why Measurement Matters in Manufacturing and Quality Control

In industrial settings, accurate measurement affects nearly every stage of the production lifecycle:

· Design verification: Ensuring that parts and products conform to engineering specifications.

· Quality assurance: Verifying tolerances and identifying deviations before components reach customers.

· Process optimisation: Using measurement data to improve manufacturing accuracy, reduce waste, and enhance efficiency.

· Compliance and standards: Meeting regulatory and industry benchmarks for product safety and performance.

Measurement also fundamentally supports quality management systems, traceability, and continuous improvement methodologies such as Six Sigma and ISO standards.

Types of Measurement Methods

Measurement can be conducted through different approaches depending on the application:

Direct Measurement

Direct measurement refers to a method where the target object comes into contact with the measuring system, allowing its length, height, or other dimensions to be read directly. Although direct measurement yields immediate results, the skill level of the operator can influence the outcome, meaning errors may still occur.

Indirect Measurement

Determines a value based on related references or secondary quantities—for example, using a gauge block to infer the height difference of a feature. This approach is often used in comparative measurement methods.

Measurement Tools and Industrial Applications

Modern industrial measurement ranges from traditional hand tools to advanced systems:

· Laser displacement sensors for high-precision dimensional analysis

· Non-contact optical measurement systems for fragile or complex shapes

· Inline measurement systems integrated into production lines

· Data acquisition and automation platforms for real-time process control

To explore solutions that enhance measurement accuracy and workflow efficiency, see DADISICK's industrial measurement solutions and discover how our technology supports improved quality outcomes.

Best Practices for Measurement Success

1. Define Measurement Objectives Clearly: Know what attributes you need to measure and why.

2. Choose the Right Measurement Tools: Match tools to the precision and tolerance requirements of your application.

3. Ensure Calibration and Traceability: Maintain regular calibration routines to guarantee accurate, traceable results.

4. Train Operators Effectively: Skilled personnel reduce measurement error and improve data reliability.

5. Integrate Data with Quality Systems: Use measurement results to feed into quality dashboards and process improvement frameworks.

Conclusion: Measurement Is More Than Numbers

Measurement is a core activity in industrial production that provides the quantitative foundation for product evaluation, compliance verification, and process improvement. Understanding the difference between measurement and inspection helps manufacturers streamline quality workflows and make data-driven decisions. With advanced measurement systems from DADISICK, businesses can achieve higher accuracy, better production insights, and greater operational efficiency.

Recommended Industrial Automation Safety Sensors

Output method: NPN/PNP+analog+RS485

Resolution: 1mm

Laser type: red semiconductor laser Class II laser 655+10nm<1m

Reaction time: 50-200ms

Detection range: 50-500 mm

Material: copper nickel plating, plastic fittings

Connection type: 5-pin M12 connector

Output method: analog voltage + analog current

Detection range: 5000 mm, 15000 mm

Material: Nickel-copper alloy

Connection type: 3pin/4pin with 2M cable

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Similar Posts You May Be Interested in