Choosing the Right Safety Door Switch: A Comparative Guide to Non-Locking, Locking and Non-Contact Types

- Share

- publisher

- Zoe

- Issue Time

- Nov 12,2025

Summary

Choosing the right safety door switch isn’t just about selecting a sensor for a guard door—it’s about matching your machine risk profile, operational environment, maintenance regime and safety targets. Whether you go with a non-locking switch, a full locking interlock switch, or a high-reliability non-contact switch, making the right decision helps protect personnel, maintain uptime and ensure compliance.

In industrial automation, guarding doors and machine access points play a vital role in protecting personnel and ensuring uninterrupted production. A properly specified safety door switch (sometimes called a safety interlock switch) is more than just a door-sensor—it ties the guard status into the machine’s safety logic, preventing dangerous operation when a door is open and, in many cases, locking the door during hazardous motion.

In this article, we compare three principal types of safety door switches: non-locking (no locking force), locking (with locking force), and non-contact types. We explore their working principles, typical applications, advantages and limitations, and offer guidance on how to choose the right type for your equipment.

Basics of Safety Door Switches

Safety door switches (or safety interlock switches) are installed on movable guards—doors, covers, hoods—that open into hazardous zones. When the guard is closed and the switch confirms safe condition, the machine may run. When the guard is open, the switch sends a signal to stop or keep the machine in a safe state.

Key safety standards to keep in mind include ISO 14119 (“Safety of machinery — Interlocking devices associated with guards — Principles for design and selection”) and ISO 13849‑1 (Performance levels for safety-related parts of control systems).

• When selecting a safety door switch the critical factors include:

• When selecting a safety door switch the critical factors include:

• The guard’s status detection reliability (closed/open)

• Whether the door must be locked during machine operation

• Environmental conditions (dust, oil, cleaning, vibration)

• Installation space and alignment requirements

• Maintenance and lifecycle costs

Three Types of Safety Door Switches

Non-Locking Type (no locking force)

Definition & Principle

A non-locking safety door switch is designed to detect the guard closed/open status, but does not physically lock the guard in the closed position while the machine is running. Typically it uses a mechanical actuator or key insertion: when the door closes, the actuator engages and the switch closes; when the door opens, the switch opens and the machine is stopped.

Typical Applications

• Low- to medium-risk machines where the hazard stops immediately when the guard opens.

• Simple guarding doors where locking is not required.

• Cost-sensitive applications.

Advantages

• Simple structure, easier installation and maintenance

• Lower upfront cost

Limitations

• No physical prevention of door opening during machine operation → not suitable for machines with long coasting, high inertia, or high personnel access risk

• Mechanical contact parts may wear in harsh environment

| OX-D2 & OX-D3 Series | ||||

| Model | Contact composition (Door + Lock monitoring) | Head materials | Connection | Mechanical life |

| OX-D2-CO | CO (1NC+1NO) | Plastic | M20 | 1,000,000 times |

| OX-D2-2C | 2C (2NC) | |||

OX-D3-2CO | 2CO (2NC+1NO) | |||

OX-D3-3C | 3C (3NC) | |||

Locking Type (with locking force)

Definition & Principle

Locking safety door switches go beyond status detection: they physically lock the guard while hazardous motion may still be active. Two common actuation modes:

• Power-to-lock: Door is unlocked by default; when the machine is running or during hazardous motion the device energises to lock the door.

• Power-to-release: Door is locked by default (spring-locked or similar) and only releases when it is safe (machine stopped, residual motion cleared). Locking is often essential when the machine cannot stop instantaneously, or when personnel access during residual motion must be prevented.

Typical Applications

• High-risk machines (large inertial loads, robots, automated press lines)

• Equipment where personnel access may coincide with hazardous motion or STOP condition is delayed

• Systems requiring high Performance Level (PL e) or SIL3

Advantages

• Stronger protection – prevents door opening until safe state is reached

• Helps meet higher safety requirements

Limitations

• More complex installation: lock mechanism, monitoring contacts

• Higher cost, more maintenance

• Requires proper alignment and door structure to support locking

OX-W2 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition (Door + Lock monitoring) |

| Solenoid Lock / Mechanical Release | OX-W2-CO/CO-GD-J | Mechanical Lock / Solenoid Release | OX-W2-CO/CO-GC-J | CO/CO (1NC/1NO+1NC/1NO) |

| OX-W2-CO/2C-GD-J | OX-W2-CO/2C-GC-J | CO/2C (1NC/1NO+2NC) | ||

OX-W2-2C/CO-GD-J | OX-W2-2C/CO-GC-J | 2C/CO (2NC+1NC/1NO) | ||

OX-W2-2C/2C-GD-J | OX-W2-2C/2C-GC-J | 2C/2C (2NC+2NC) | ||

OX-W2-C2O/C-GD-J | OX-W2-C2O/C-GC-J | C2O/C (1NC/2NO+1NC) | ||

OX-W2-3C/C-GD-J | OX-W2-3C/C-GC-J | 3C/C (3NC+1NC) | ||

OX-W2-2CO/C-GD-J | OX-W2-2CO/C-GC-J | 2CO/C (2NC/1NO+1NC) | ||

OX-W2-C/3C-GD-J | OX-W2-C/3C-GC-J | C/3C (1NC+3NC) | ||

OX-W2-C/C2O-GD-J | OX-W2-C/C2O-GC-J | C/C2O (1NC+1NC/2NO) | ||

OX-W2-C/2CO-GD-J | OX-W2-C/2CO-GC-J | C/2CO (1NC+2NC/1NO) | ||

OX-W2-O/3C-GD-J | OX-W2-O/3C-GC-J | O/3C (1NO+3NC) | ||

OX-W2-O/2CO-GD-J | OX-W2-O/2CO-GC-J | O/2CO (1NO+2NC/1NO) | ||

OX-W2-2C/2O-GD-J | OX-W2-2C/2O-GC-J | 2C/2O (2NC+2NO) | ||

OX-W2-2O/2C-GD-J | OX-W2-2O/2C-GC-J | 2O/2C (2NO+2NC) | ||

| OX-W3 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition(Door + Lock monitoring) |

Solenoid Lock / Mechanical Release | OX-W3-C/C-GD-J | Mechanical Lock / Solenoid Release | OX-W3-C/C-GC-J | C/C (1NC+1NC) |

| OX-W3-/2C-GD-J | OX-W3-/2C-GC-J | /2C (2NC) | ||

OX-W3-2C/-GD-J | OX-W3-2C/-GC-J | 2C/ (2NC) | ||

OX-W3-CO/-GD-J | OX-W3-CO/-GC-J | CO / (1NC/1NO) | ||

OX-W3-O/C-GD-J | OX-W3-O/C-GC-J | O/C (1NO +1NC) | ||

| OX-W3-/CO-GD-J | OX-W3-/CO-GC-J | /CO (1NC/1NO) | ||

| OX-W5 Series | ||||

| Lock/Release method | Model | Lock/Release method | Model | Contact composition(Door + Lock monitoring) |

| Solenoid Lock / Mechanical Release | OX-W5-2CO/2CO-GD-J | Mechanical Lock / Solenoid Release | OX-W5-2CO/2CO-GC-J | 2CO/2CO(2NC/1NO+2NC/1NO) |

OX-W5-3C/2CO-GD-J | OX-W5-3C/2CO-GC-J | 3C/2CO (3NC+2NC/1NO) | ||

OX-W5-2CO/3C-GD-J | OX-W5-2CO/3C-GC-J | 2CO/3C (2NC/1NO+3NC) | ||

| OX-W5-3C/3C-GD-J | OX-W5-3C/3C-GC-J | 3C/3C (3NC+3NC) | ||

Non-Contact Type

Definition & Principle

Non-contact safety door switches detect the guard status without mechanical contact. Common technologies: coded magnets, RFID/encoder actuators, magnetic sensors. Because there is no mechanical wear or contact between actuator and sensor, they are well suited for demanding environments.

Typical Applications

Typical Applications

• Environments with dust, oil, wash-down, high vibration

• Automated logistics, intralogistics, AGV/AMR guard doors

• Food / pharmaceutical clean-room doors

Advantages

• Minimum wear, long life, high reliability

• Resistant to misalignment, debris

• Ideal for frequent opening/closing and harsh conditions

Limitations

• If without integrated locking, may offer only status detection (not physical lock) → may not suffice for high-risk applications

• Cost may be higher than simple mechanical switches

OX-R1 Series RFID Non-contact Safety Door Switch | |||

OX-R1-FN-S-P1 | 4-core direct wiring dual NPN output 2M line | ||

OX-R1-FP-S-P1 | 4-core direct wiring dual PNP output 2M line | ||

OX-R1-EN-S-P1 | 6-core direct wiring dual NPN output with cascade 2M line | ||

OX-R1-EP-S-P1 | 6-core direct wiring dual PNP output with cascade 2M line | ||

OX-R1-FN-D-P1 | 4-core direct wiring dual NPN output 2M line, Actuator with unique code | ||

OX-R1-FP-D-P1 | 4-core direct wiring dual PNP output 2M line, Actuator with unique code | ||

OX-R1-EN-D-P1 | 6-core direct wiring dual NPN output with cascade 2M line, Actuator with unique code | ||

OX-R1-EP-D-P1 | 6-core direct wiring dual PNP output with cascade 2M line, Actuator with unique code | ||

OX-C1 Series Coded Magnetic Non-Contact Safety Door Switch | |||

| OX-C1-2O-P1A | 2 Normally Open, Direct Cable Output, 2m | ||

| OX-C1-1C1O-P1A | 1 Normally Open, 1 Normally Closed, Direct Cable Output, 2m | ||

| OX-C1-2C-P1A | 2 Normally Closed, Direct Cable Output, 2m | ||

Comparative Summary & Selection Guidance

| Type | Locking Feature | Contact Mode | Suitable Environment | Typical Applications | Strengths | Weaknesses |

| Non Locking | None | Mechanical | Standard industrial | Low-risk guard monitoring | Low cost, simple | No lock protection, limited for high risk |

| Locking | Physical lock present | Mechanical + lock | Medium to high hazard | Large inertia machines, robots, presses | Strong protection | Higher cost & maintenance |

| Non-Contact | Detection only (optional lock) | Magnetic/optical | Harsh / cleaning / logistics | Food, pharma, logistics doors | Durable, minimal wear | May lack physical lock if not specified |

Related Products

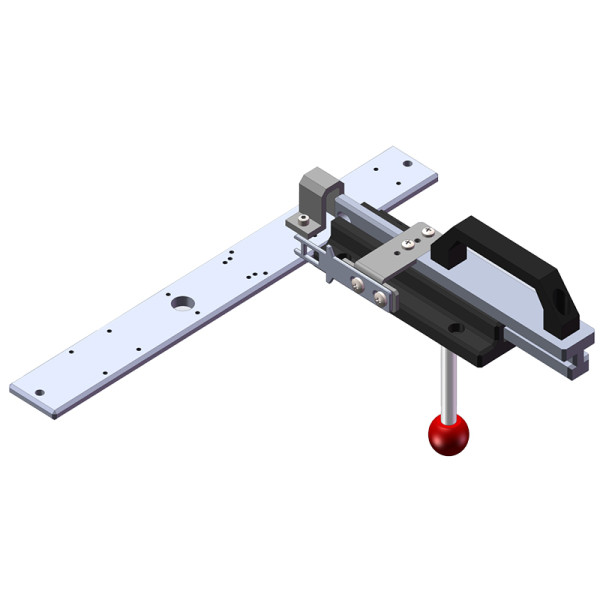

• 4 sets of gold-plated silver alloy contacts

• PA66 flame-retardant housing

• 14 contact combinations

• Locking force 1300 N

• Indicator light + emergency release

• Optional rear release function

• Compatible with 11 types of operating keys

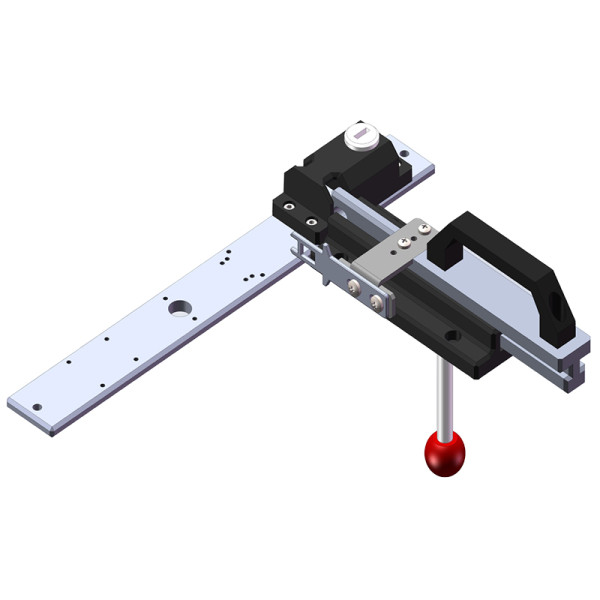

• 2 sets of gold-plated silver alloy contacts

• PA66 flame-retardant housing

• 6 contact combinations

• Locking force 1300 N

• Indicator light + emergency release

• Compatible with 11 types of operating keys

• Compact design saves space

• 6 sets of silver alloy gold-plated contacts

• PA66 flame-retardant housing

• 4 contact combinations

• DC 24 V / AC 110 V

• Locking force 1300 N

• Indicator light + emergency release

• Optional front / side emergency release

• Compatible with 11 types of operating keys

• Gold-plated silver alloy contacts for the entire series

• PA66 flame-retardant housing

• Up to 3 contact configurations

• Suitable for standard and micro loads

• Compatible with 11 types of operating keys

• Adjustable for 8 key insertion methods

• Comes with a PG13.5 cable gland from the factory

Used for monitoring places such as safety doors and windows.

Horizontal distance: Conduction, min: 10 mm

Vertial distance: Conduction, min: 8 mm

(Order separately)

Similar Posts You May Be Interested in