How to Calculate Safety Distance for Safety Light Curtains (ISO 13855 Explained with Practical Example)

- Share

- Issue Time

- Dec 13,2025

Summary

Learn how to calculate the safety distance for safety light curtains according to ISO 13855. This article explains the formula, key parameters, and provides a practical calculation example using the DADISICK QT08-20-140-2BB safety light curtain for machine safeguarding applications.

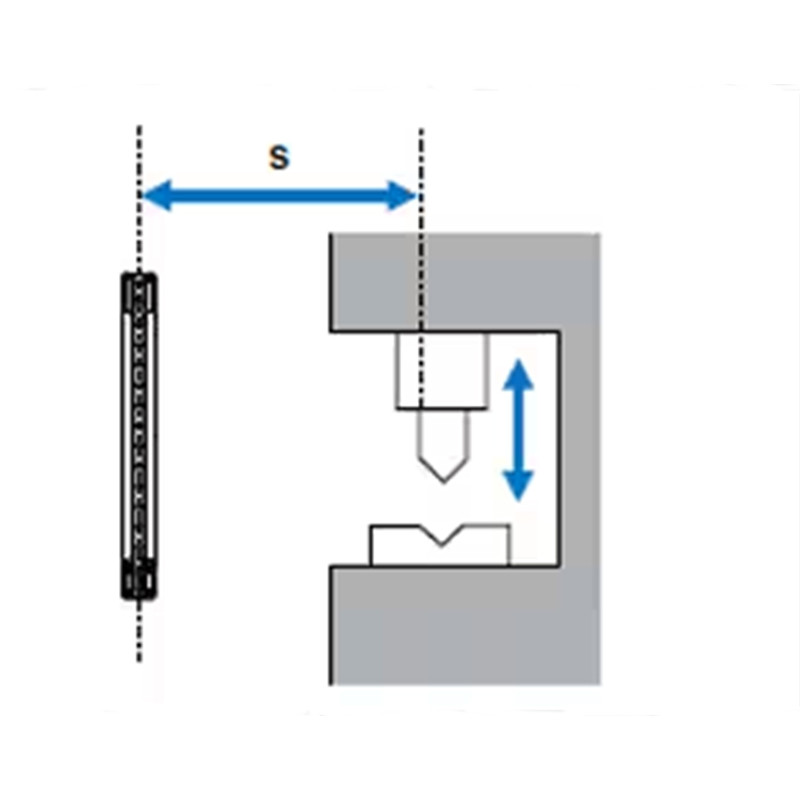

In machine safety systems, a safety light curtain is only effective if it is positioned at the correct safety distance. Even a certified safety light curtain cannot prevent injury if a person can reach the hazard before the machine stops.

Safety distance calculation is therefore not optional—it is a mandatory engineering step required by international safety standards such as ISO 13855 and ISO 13849-1. This calculation ensures that once the protective field is interrupted, the machine will stop before a hazardous movement can be reached.

This article focuses exclusively on how to calculate the safety distance for safety light curtains, using a real industrial product example and a step-by-step, engineer-friendly method.

What Is Safety Distance in Machine Safety?

Safety distance is the minimum required separation between the protective field of a safety light curtain and the hazardous motion or point of operation. The purpose is simple: when the detection field is interrupted, the machine must stop before a person can reach the danger zone. Unlike fixed guards, safety light curtains rely on reaction time, which makes distance calculation a mandatory engineering task rather than a rough installation estimate.

Applicable International Standard for Safety Distance Calculation

The most widely applied international standard for safety distance calculation is ISO 13855:

Safety of machinery — Positioning of safeguards with respect to the approach speeds of parts of the human body

This standard defines:

· Human approach speeds

· Calculation formulas

· Additional intrusion distances based on sensor resolution

It is commonly used together with IEC 61496 for electro-sensitive protective equipment such as safety light curtains.

gaiSafety Distance Calculation Formula Explained

The most widely used standard for calculating safety distance for non-contact protective devices like light curtains is ISO 13855. The minimum safety distance S (in mm) is calculated using a general formula:

Mounting, Alignment, and Mechanical Considerations

Rigid mounting and vibration control

Even small angular shifts cause beam misalignment. Mount transmitters and receivers to rigid structures; avoid flexible frames. If unavoidable, use vibration dampers or additional bracing. Torque mounting hardware to specified values and use thread-lock compounds in high-vibration environments.

Alignment techniques and tools

Use built-in LEDs, alignment lasers, or portable detectors to align beams precisely. After initial alignment, lock adjustment points, and running a cyclic test (operating the machine at speed while checking for spurious faults). Re-verify alignment after the first week of operation.

Avoiding reflections and optical noise

Polished surfaces, glass, and thin plastic films can reflect infrared beams and create ghost signals or masking. Keep a clearance (typically 50–100 mm depending on geometry) from reflective panels, or fit anti-reflection covers. For welding environments, use shields and synchronize with weld cycles or choose filters tolerant to arc light.

Wiring, OSSD Outputs, and Safety Integration

Using proper safety relays and controllers

Light curtains produce safety outputs (often OSSD). These outputs must connect to certified safety relays or safety PLCs that provide dual-channel monitoring, cross-circuit detection, and safe restart logic. DADISICK's safety relays are designed for such integration and include required diagnostic features.

Wiring best practices and EMC considerations

· Use separate conduits for power and signal cables.

· Ground shields correctly at one end to avoid ground loops.

· Maintain recommended wire lengths and use recommended cable types to preserve timing and diagnostics.

· Wherever possible, route safety wiring away from drives, inverters, and heavy machinery to reduce EMI risk.

Cross-circuit protection and redundancy checks

Redundancy only provides safety if channels are independent. Avoid common wiring segments between channels; each channel should be physically separated where possible. Check for common cause failure exposures (e.g., a clamp crushing both channels).

Functional Testing, Validation, and Commissioning

Beam interruption and approach tests

Use calibrated test rods or standardized test specimens to block beams at different heights and positions. Test both single and multi-beam interruptions. Validate detection under dynamic conditions (moving conveyors, part ingress).

Response time and safety chain verification

Trigger a beam interruption and measure elapsed time to machine stop (preferably with an oscilloscope or test logger). Compare with the calculated T used in the safety distance. Reconcile any discrepancies—do not accept measured times longer than calculated.

Documented verification and sign-off

Create a commissioning checklist covering alignment, safety distance verification, wiring inspection, E-stop function, controlled restarts, and training. Have responsible engineers sign off; retain records for compliance and insurance.

Commissioning Scenarios and Edge Cases

Muting and blanking—use with caution

Muting (temporary suppression of material flow) and blanking (permanent suppression of certain beams for part passage) are powerful but risky. Implement muting only with clear logic (sensors that detect material flow) and safeguard against operator-induced bypass. Verify muting logic under fault conditions.

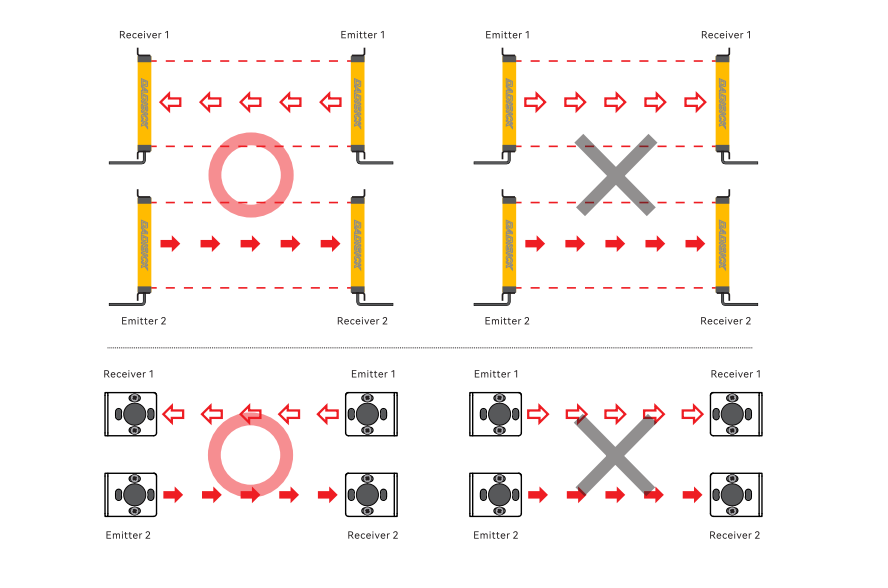

Cascading and multi-sided protection

For large or multi-access areas, cascading multiple curtains is common. Use curtains that support auto-cascade or synchronized beams to prevent cross-talk. Ensure each cascade link includes safe verification and does not introduce single points of failure.

Tooling changes and re-validation

After tooling changes (dies, fixtures), revalidate protection height, safety distance, and any blanking/muting logic. Even small tooling differences can alter intrusion geometry and invalidate prior calculations.

Maintenance, Periodic Testing, and Long-Term Reliability

Routine inspection schedule

Define inspection intervals based on duty cycles and environment (weekly for dirty/abrasive environments, monthly in cleaner settings). Inspections should include visual checks, alignment verification, and beam status LED readings.

Predictive diagnostics and using device diagnostics

Modern curtains supply diagnostic outputs (alignment error, beam block fault, internal fault). Integrate diagnostics into maintenance dashboards (via IO-Link or Ethernet) to predict failures before they become critical.

Replacement planning and lifecycle management

Track mean time to dangerous failure (MTTFd) data and plan component replacement/recalibration before diagnostic thresholds degrade. Maintain spares for critical models to reduce downtime.

Common Mistakes and How to Avoid Them

Mistake — Relying on assumed stopping time

Measure machine stopping time rather than relying on catalog numbers. Real machines with worn brakes or variable loads can have much longer stopping times.

Mistake — Using the wrong approach speed constant (K)

Use a conservative approach if operator behavior is uncertain. If operators frequently rush or use tools, use higher K values to ensure the safety distance is sufficient.

Mistake — Treating muting as a convenience rather than a controlled function

Muting must be rigorously validated; do not use muting to hide design deficiencies.

Conclusion — Build Safety into the Installation Process

A safety light curtain is not a plug-and-play component; it's a safety system element. Quality installations derive from careful risk assessment (defining PLr), measured timing and distance calculations, correct device selection (resolution, type), proper mounting and wiring, and documented validation and maintenance. When combined with certified safety relays and controllers, and when engineers follow structured commissioning and change-control processes, light curtains reliably protect operators and support productive automation.

For integrated safety systems—light curtains, relays, and performance guidance, etc.—DADISICK provides a full portfolio of compliant solutions to help you design, install, and maintain safe machines.

Related Safety Devices

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

By converting from the laser into electrical signals. determine various characteristics,distance, displacement, or position.

Used for monitoring places such as safety doors and windows.

Similar Posts You May Be Interested in