What is the muting function of a safety light curtain?

- Share

- publisher

- Zoe

- Issue Time

- Sep 22,2025

Summary

This page will explain what muting means, how it works, what components are involved, practical design considerations, and safety rules you must follow.

What Is the Muting Function of Safety Light Curtains? (Safety Light Curtain Muting)

Safety light curtains are widely used to protect people from hazardous machine parts. However, in many industrial processes, boxes, pallets, or products need to pass through a protected area without stopping the machine each time. This is where safety light curtain muting comes into play. Muting allows material to pass temporarily while still ensuring personnel safety.

What Is Muting?

Definition: Muting is an automatic, temporary suspension of a safety light curtain’s protective function (or similar electrosensitive protective device), triggered under predefined conditions so that material—not people—can pass through a guarded opening.

Key points:

● It’s automatic (no manual bypassing).

● It’s temporary and limited in time.

● It must not reduce the overall safety level.

Why Muting Is Needed?

● In many manufacturing lines, goods or materials need to pass through a safety guarded zone (for example a conveyor entering a machine) regularly. Without muting, each time material approaches, the system would shut down or stop, hurting productivity.

● Muting balances safety vs operational efficiency: you protect people while allowing material flow when safe.

● Typical applications: pallet loading/palletizing, automated packaging, load/unload zones where materials move but personnel should not.

How Safety Light Curtain Muting Works — Basic Mechanism

Below is the general sequence of how muting is implemented:

| Step | What Happens | ||

| Triggering | Muting sensors at the entry detect the presence of material. | ||

| Sequence check | The control logic verifies the order and combination of triggered sensors to confirm it’s “material” and not a person. | ||

| Muting time window | The light curtain is muted for a short, preset time so the material can pass. | ||

Status indication | A lamp or signal indicates when muting is active. | ||

Protection restored | Once the material has passed or time expires, normal protection is immediately restored. | ||

What Components Are Needed for Muting?

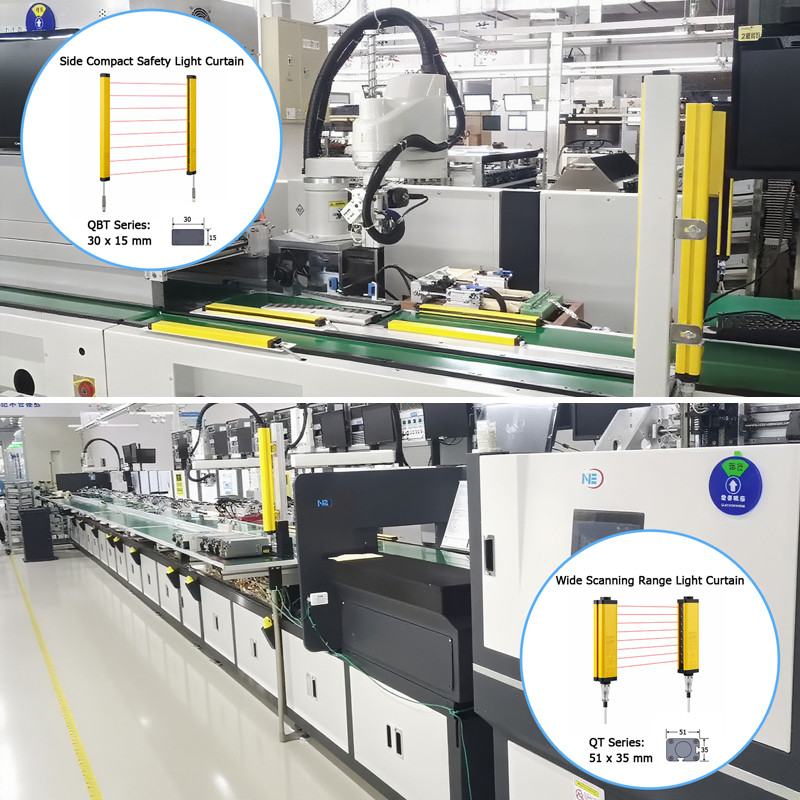

Safety light curtain itself (or other electro-sensitive protective device): the main safety barrier.

Muting sensors: often optical (through-beam, retroreflective) or presence sensors. These detect material in predefined positions.

Muting controller / logic: either in a safety controller or in a safety PLC or relay module; must be certified.

Indicator lamp or beacon: shows when muting is active.

Mounting hardware/protective covers: ensure correct alignment and protect sensors against mechanical damage.

Mounting hardware/protective covers: ensure correct alignment and protect sensors against mechanical damage.

Common Configurations and Examples

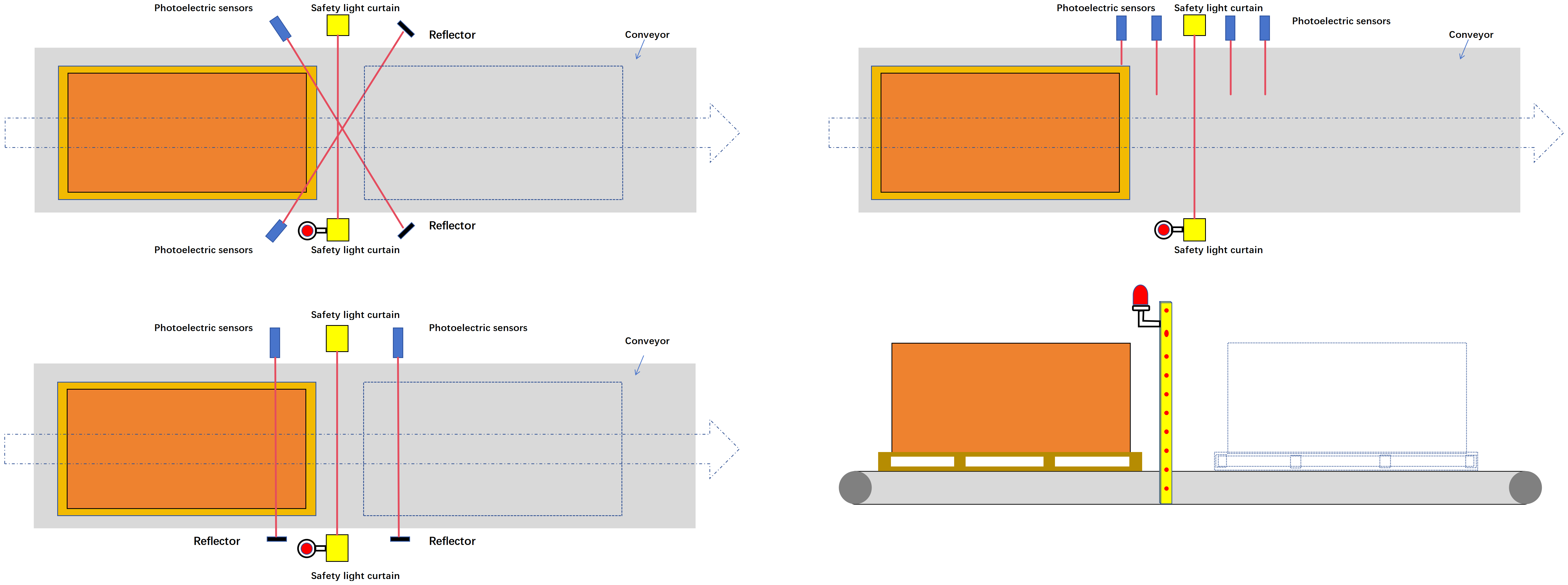

Two-sensor parallel: one at entry, one at exit.

● Crossed (T) layout: sensors cross to check orientation.

● Four-sensor: extra checks for large or irregular loads.

● Choose by pallet size, product shape, and direction of travel.

Two Sensor Muting Example

In a conveyor system, one photoelectric sensor is installed in front of the safety light curtain and another behind it. Their beams are arranged in a cross (T-shaped) pattern across the conveyor path. When a pallet approaches and moves in the correct direction of travel, it first interrupts one beam and then the other, in a specific order. The safety controller recognizes this sequence as legitimate material flow and activates muting, allowing the pallet to pass through the light curtain without stopping the machine. If a person tries to enter from the side or in the wrong direction, the sequence will not match, and muting will not be triggered. Once the pallet has passed, the muting function ends automatically, and full protection is restored.

Design Considerations and Best Practices

● To ensure muting is reliable and safe, follow these guidelines:

● Risk assessment first: Identify hazards, types and sizes of materials, and possible human access.

● Sensor placement and alignment: Position sensors so only material triggers them, not people. Misalignment can cause false muting or muting failure.

● Time/velocity calculation: Calculate the muting window based on material length and conveyor speed. Too short → material won’t fully pass; too long → increased safety risk.

● Mechanical protection of sensors: Prevent damage from moving goods or environmental factors.

● Diagnostics and monitoring: The system should detect sensor faults or incorrect triggering sequences and issue warnings. Maintenance should include cleaning and alignment checks.

● No permanent bypassing: Muting must never be used as a manual override for safety devices.

● Documentation and validation: Keep risk assessments, wiring diagrams, FAT/SAT test reports, and compliance records for audits.

Simple muting time calculation example:

Muting time (s) ≈ (Maximum material length (m) + safety margin (m)) ÷ conveyor speed (m/s)

Common Problems and Quick Fixes

● False muting: Often caused by misalignment, reflection, or wrong sensor type → check alignment and use proper sensors.

● No muting when required: Verify wiring, power supply, sensor blockage, and controller logic.

● Material stuck longer than muting time: Adjust the time window after reassessing risks.

● Audit issues: Ensure all documents, risk assessments, and certified components are available.

Similar Posts You May Be Interested in