Human-Machine Collaborative Safety: How to Ensure Safety When Using Laser Cutting Machines?

- Share

- publisher

- Zoe

- Issue Time

- Apr 1,2025

Summary

Enhance safety in laser cutting operations with the DADISICK QSA Series Safety Light Barrier. Ensure fast response, intelligent detection, and multi-sided protection to prevent workplace accidents while maintaining efficiency.

Human-Machine Collaborative Safety: How to Ensure Safety When Using Laser Cutting Machines?

"A severe injury occurred in a laser cutting workshop due to the absence of protective measures, leading to an unexpected machine start..."

Statistics show that 70% of laser cutting accidents are caused by failures in protective equipment or improper operation. As a business leader, how can you ensure both production efficiency and comprehensive safety protection?

QSA Series Industrial Safety Light Barrier – Efficient and Precise Safety Protection

In the high-risk environment of laser cutting, the DADISICK QSA Series Industrial Safety Light Barrier provides an intelligent and efficient protection solution:

• Ultra-fast response for instant protection: Response time ≤15ms, ensuring immediate shutdown before hazards occur.

• Flexible spacing options to meet various safety needs:

1. Finger protection: 20mm spacing

2. Hand protection: 40mm spacing

3. Body protection: 80mm/200mm spacing

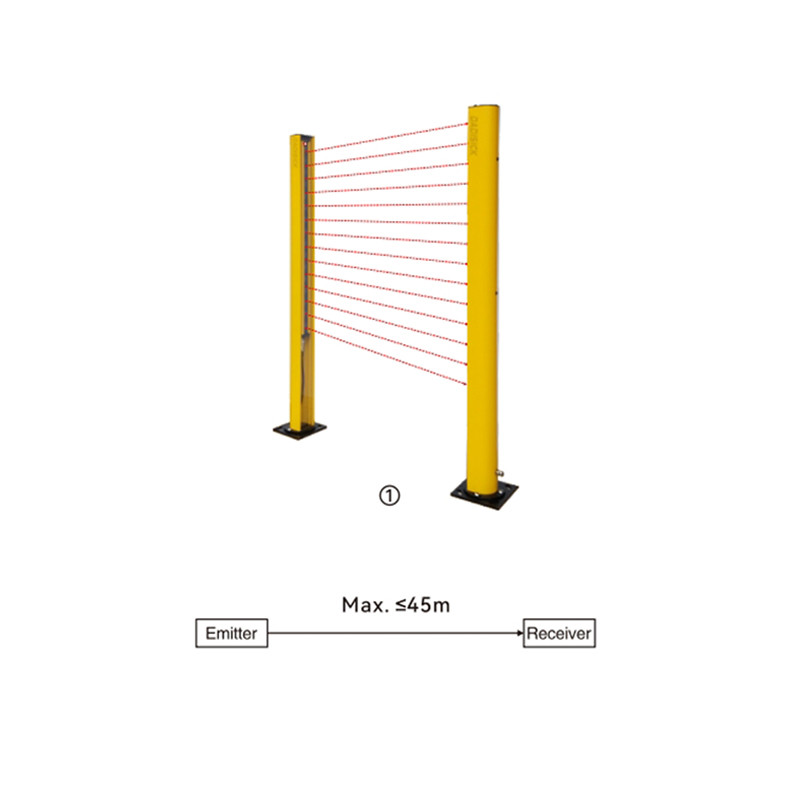

• Long-distance detection, ideal for large-scale equipment: The emitter and receiver achieve a maximum detection range of 45m, making it suitable for large laser cutting machines.

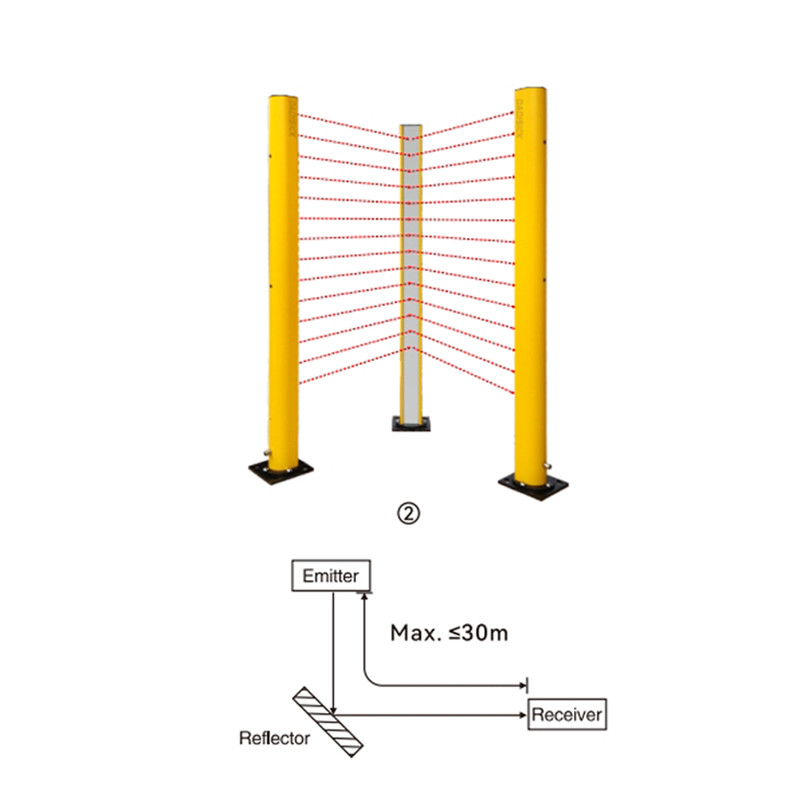

• Multi-sided protection, freely configurable:

1. Single-sided protection

One set of safety light barriers

2. Double-sided protection

One set of safety light barriers + 1 reflector

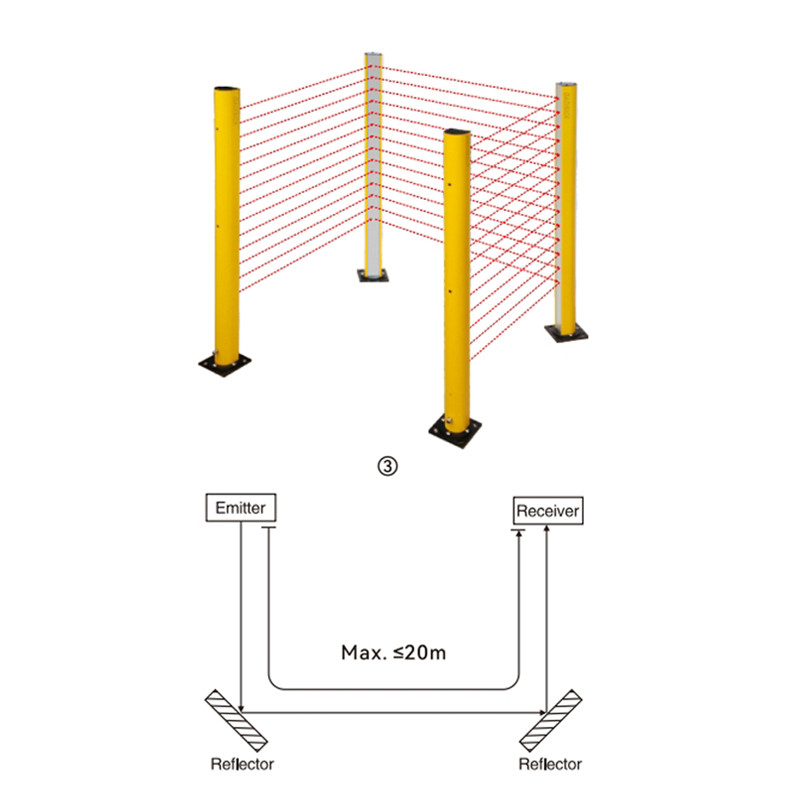

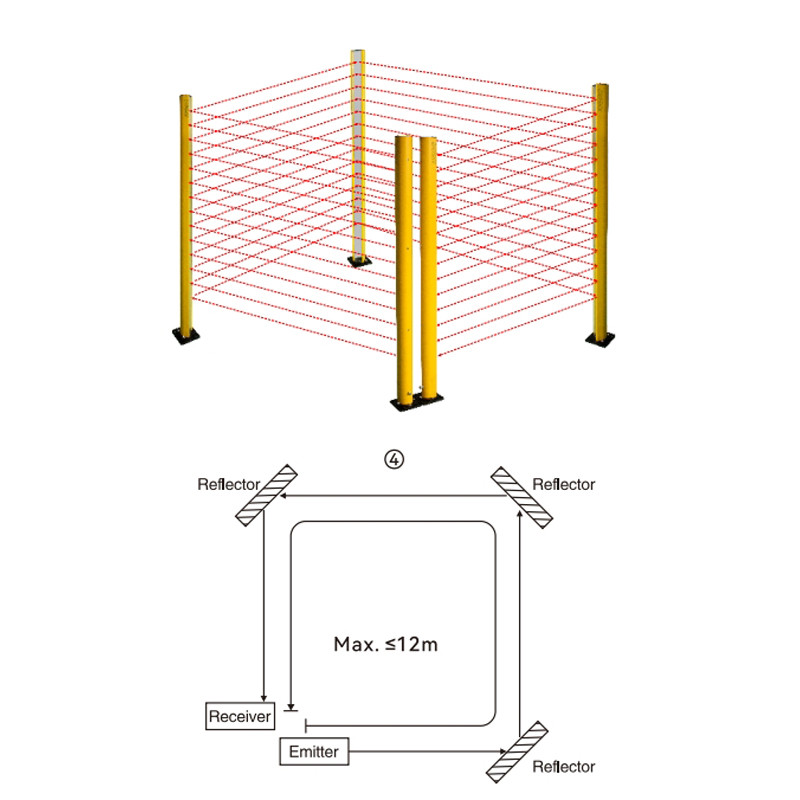

3. Three-sided protection

One set of safety light barriers + 2 reflectors

4. Four-sided protection

One set of safety light barriers + 3 reflectors

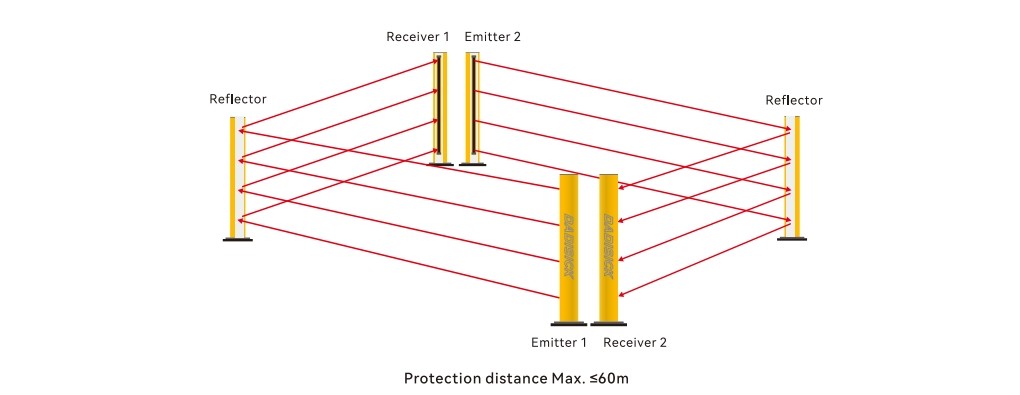

5. Long-range four-sided protection

Two sets of safety light barriers + 2 reflectors

• Intelligent self-diagnosis for system stability: Built-in polarity, short-circuit, and overload protection. If a failure occurs, the system prevents false signals from being sent to the controlled device, avoiding malfunctions.

• Strong anti-interference capability: Effectively blocks 99% of electromagnetic interference, strobe lighting, welding arcs, and ambient light, ensuring precise and reliable detection.

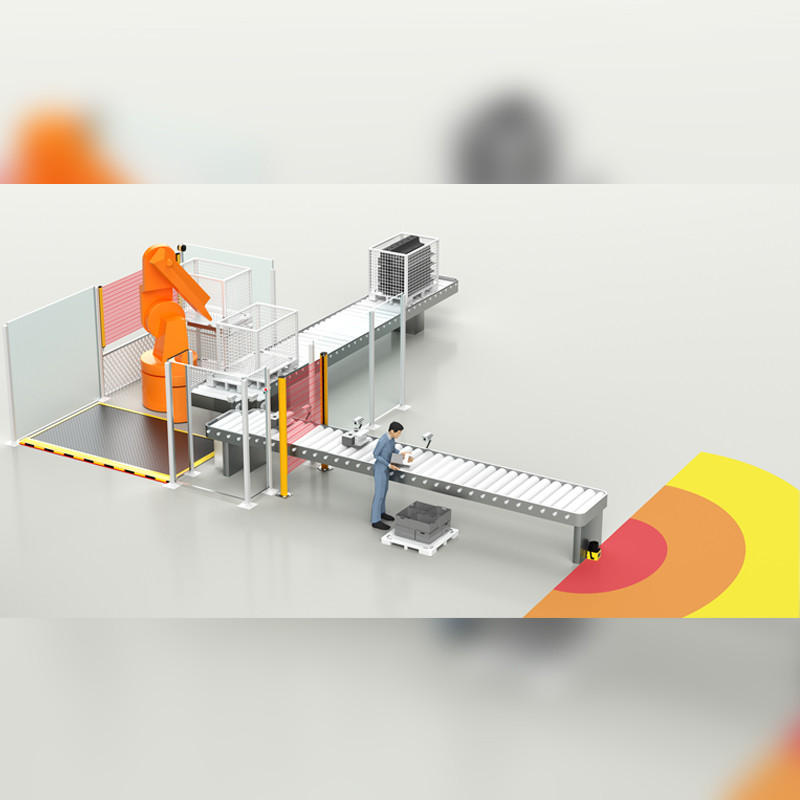

Human-Machine Collaborative Safety: From Passive Protection to Active Prevention

Traditional safety measures rely on warning signs or physical barriers, which come with limitations—barriers reduce operational flexibility, and warning signs are often ignored. DADISICK safety light barriers introduce intelligent technology, shifting safety from passive to active prevention:

• Smart Warning System: Real-time monitoring of the working area. If a worker's hand or body enters the hazardous zone, the system triggers an audible-visual alarm and initiates an emergency stop.

• Misoperation Prevention: The built-in logic module differentiates between normal workpiece movement and accidental human intrusion, preventing unnecessary machine stoppages and improving productivity.

• Visualized Safety Training: New employees often overlook hazardous zones. The safety light barrier projects a clear warning line, making boundaries visible and reducing training costs.

Enhancing "Restricted Access Control" for a Safer Work Environment

Beyond standardized protection, the QSA series safety light barrier further enhances workplace safety by reducing unauthorized access risks in laser cutting machine entry points:

• Automated Access Control: Integrated with factory automation systems, allowing only authorized personnel to access the machine area. Unauthorized personnel or objects trigger an immediate alarm and machine halt.

• Remote Monitoring & Diagnostics: Supports real-time system monitoring, ensuring continuous operation and safety status tracking.

Related Safety Sensors

Beam spacing: 200mm

Number of optical axes: 22

Protection height: 4200mm

Safety Curtain outputs (OSSD): 2 PNP

Beam spacing:200mm

Number of optical axes: 18

Protection height: 3400mm

Safety sensors for machines output (OSSD):2 PNP

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.