How to Calculate Safety Distance for Safety Light Curtains (ISO 13855)

- Share

- Issue Time

- Dec 13,2025

Summary

Learn how to calculate safety distance for safety light curtains according to ISO 13855. This article explains the safety distance formula, key parameters, and a practical calculation example to support compliant and effective machine safety design.

In machine safety systems, a safety light curtain is only effective if it is positioned at the correct safety distance. Even a certified safety light curtain cannot prevent injury if a person can reach the hazard before the machine comes to a complete stop. Safety distance calculation is therefore not optional—it is a mandatory engineering step required by international safety standards such as ISO 13855 and ISO 13849-1. This calculation ensures that, once the protective field is interrupted, the machine will stop before a hazardous movement can occur. This article focuses exclusively on how to calculate the safety distance for safety light curtains, using a real industrial product example and a step-by-step, engineer-friendly method.

What Is Safety Distance in Machine Safety?

Safety distance is the minimum required separation between the protective field of a safety light curtain and the hazardous motion or point of operation. The purpose is simple: when the detection field is interrupted, the machine must stop before a person can reach the danger zone. Unlike fixed guards, safety light curtains rely on reaction time, which makes distance calculation a mandatory engineering task rather than a rough installation estimate.

Applicable International Standard for Safety Distance Calculation

The most widely applied international standard for safety distance calculation is ISO 13855:

Safety of machinery — Positioning of safeguards with respect to the approach speeds of parts of the human body

This standard defines:

· Human approach speeds

· Calculation formulas

· Additional intrusion distances based on sensor resolution

It is commonly used together with IEC 61496 for electro-sensitive protective equipment such as safety light curtains.

Safety Distance Calculation Example for Safety Light Curtains (ISO 13855)

Safety Distance Formula

For vertical installation of a safety light curtain (most common configuration), ISO 13855 defines the minimum safety distance S as:

S = K × T + C

Where:

· S = Minimum safety distance (mm)

· K = Approach speed of the human body or body part (mm/s)

· T = Total system stopping time (s)

· C = Additional distance based on intrusion and sensor resolution (mm)

This formula ensures that the machine comes to a complete stop before any part of the human body can reach the hazardous area.

Component Decomposition of the Safety Distance Formula

Determine the Approach Speed (K)

ISO 13855 uses empirical data to set practical approach speeds:

· K = 2000 mm/s — Assumes the fastest intrusion speed of a hand or arm entering the protected area.

· K = 1600 mm/s — Used when the previously calculated safety distance ≥ 500 mm and where full-body approach is more relevant.

The standard suggests starting with 2000 mm/s for hand entry and, if the calculated S is ≥ 500 mm, recalculating with 1600 mm/s to reflect more conservative body movement.

Total System Stopping Time (T)

T includes all delays from when the protective field is interrupted to when the hazard motion is fully stopped:

T=t(light curtain)+t(monitor)+t(machine stop)

Where:

· t(light curtain) = response time of the light curtain (ms or s)

· t(monitor) = response time of the safety monitoring device (e.g., safety relay)

· t(machine stop) = mechanical stopping time of the machine

Each portion must be obtained from actual measurements or manufacturer specifications.

For systems requiring reliable stop signal processing, safety relays are commonly used to monitor OSSD outputs and enforce safe stop conditions.

Intrusion / Resolution Distance (C)

For vertical installations (most common), ISO 13855 defines C based on the light curtain's resolution (d) — the smallest object size it can reliably detect: C=8×(d−14)

Where:

· d = sensor resolution in mm

· The expression is used when d > 14 mm for hand/body detection

This additional distance accounts for the fact that larger beam spacing allows deeper body penetration before the protective function triggers.

We will apply the ISO 13855 method using the specifications of the DADISICK QT08-20-140-2BB Security Light Sensor (a wide-scanning safety light curtain), then derive the minimum safety distance required for a typical application.

Identify Model Parameters

From the product datasheet:

· Model: QT08-20-140-2BB

· Resolution (d): 20 mm

· Response Time (t_{light curtain}): 30 ms

· OMission: Typically, this type provides dual OSSD outputs and fast switching suitable for safety circuits.

Assumed safety monitor response time: 25 ms

Measured machine stopping time (example): 300 ms

Calculate Total Stopping Time (T)

Convert all times to seconds for calculation:

t(light curtain)=0.030s

t(monitor)=0.025s

t(machine stop)=0.300s

T=0.030+0.025+0.300=0.355s

Compute Intrusion Distance (C)

Using the formula:

C=8×(d−14)

C=8×(20−14)=48mm

Initial Safety Distance Calculation (K = 2000 mm/s)

S=2000×0.355+48

S=710+48=758 mm

So, the initial minimum safety distance is: S = 758 mm

Recalculate with Lower Approach Speed (K = 1600 mm/s)

If the initial calculation yields S ≥ 500 mm (which it does), ISO 13855 lets you recalculate using a slower approach speed:

S=1600×0.355+48

S=568+48=616 mm

Engineer Interpretation

· 758 mm is the conservative design distance based on hand approach speed.

· 616 mm can be used if justified, e.g., the application reduces direct hand intrusion, and operators are trained/controlled.

Why Recalculation with K=1600 Is Allowed

ISO 13855 notes that when the initial calculation yields a long safety distance (≥ 500 mm), a recalculation with K = 1600 mm/s lower bound is permitted for whole-body motion. However, the final safety distance should not exceed human reach into the hazard under any reasonable scenario without justification.

Why Correct Safety Distance Calculation Matters

An underestimated safety distance can result in:

· Operators reaching hazards before the motion stops

· Non-compliance during safety audits

· Increased legal and operational risk

Conversely, overly conservative distances may reduce productivity or complicate machine layout. Accurate calculation ensures both safety and efficiency.

For a deeper understanding of how stopping performance and risk reduction are evaluated within a machine safety system, refer to this detailed explanation of machine safety performance levels (PL) according to ISO 13849-1, which clarifies how stopping behavior, control reliability, and risk assessment are interconnected.

Important Notes for Practical Applications

· Always use the actual measured machine stopping time, not estimated values.

· If local regulations specify a minimum safety distance, the greater value must be applied.

· Safety distance calculation should be part of a complete risk assessment process.

· Different approach scenarios (hand vs. body) may require different K values and results.

Safety Distance Calculation for Safety Light Curtains — An Engineer's Perspective from DADISICK

Accurate safety distance calculation is a fundamental requirement in machine safeguarding, not only to meet international safety standards, but also to ensure real-world protection for operators while maintaining efficient machine operation. By correctly applying the ISO 13855 formula and using verified machine stopping times together with appropriate sensor parameters, safety light curtains can perform their intended protective function reliably.

As an engineer at DADISICK, I wrote this article to share a practical and standards-based explanation of safety distance calculation for safety light curtains, using real product parameters such as the QT08-20-140-2BB. This article is intended to help system integrators, machine builders, and safety professionals better understand how sensor resolution, stopping performance, and installation distance work together in compliant and effective machine safety designs.

Related Safety Devices

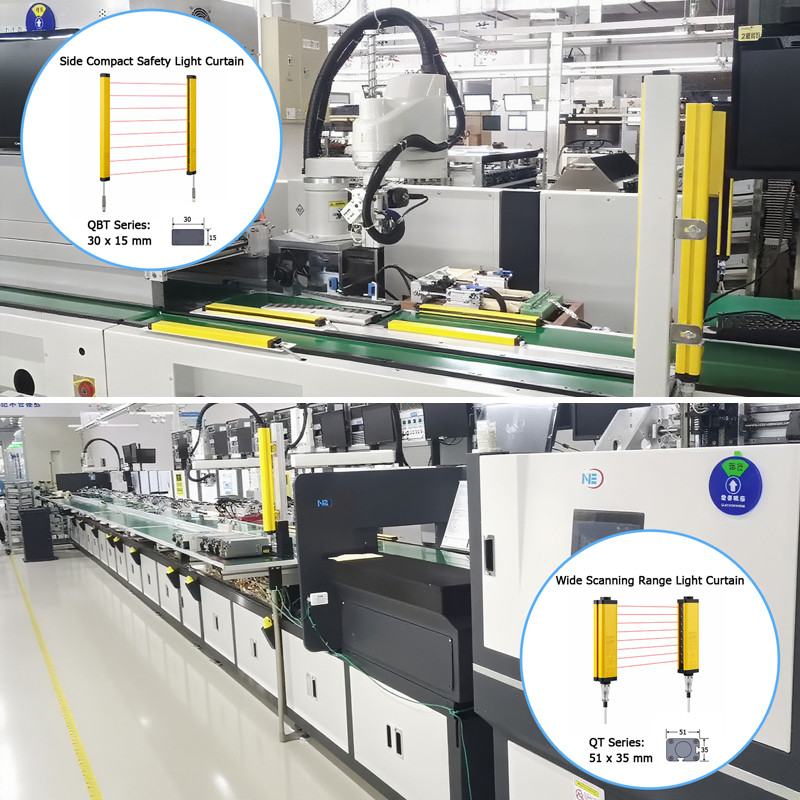

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Used for monitoring places such as safety doors and windows.

Similar Posts You May Be Interested in