Palletizing Robot Workstation Safety Guide: Boost Efficiency & Compliance

- Share

- publisher

- Zoe

- Issue Time

- Oct 25,2025

Summary

Download our FREE safety guide for palletizing robot workstations. Learn about key safety devices like laser scanners, light curtains, and safety relays to ensure worker protection and maximize production efficiency.

Robotic palletizing systems are essential in modern manufacturing and logistics for automating material handling, improving throughput, and minimizing labor intensity. However, because these systems often operate at high speeds and involve frequent human interaction, ensuring operator safety is a critical priority. This guide outlines the key safety devices and best practices to achieve both safety and efficiency in Robotic Palletizing Systems.

Safety Requirements for Robotic Palletizing Workstations

A palletizing robot workstation involves continuous motion of robotic arms, conveyors, and pallets. The typical risks include:

● Accidental entry into hazardous zones

● Human-robot collision hazards

● Equipment malfunction or misalignment requiring an emergency stop

To mitigate these risks, a comprehensive safety system combining light screens, safety switches, 2D LiDAR scanners, and pressure sensitive safety mats should be implemented.

#key safety features in modern palletizing robots

#key safety features in modern palletizing robots

Key Safety Devices and Their Functions

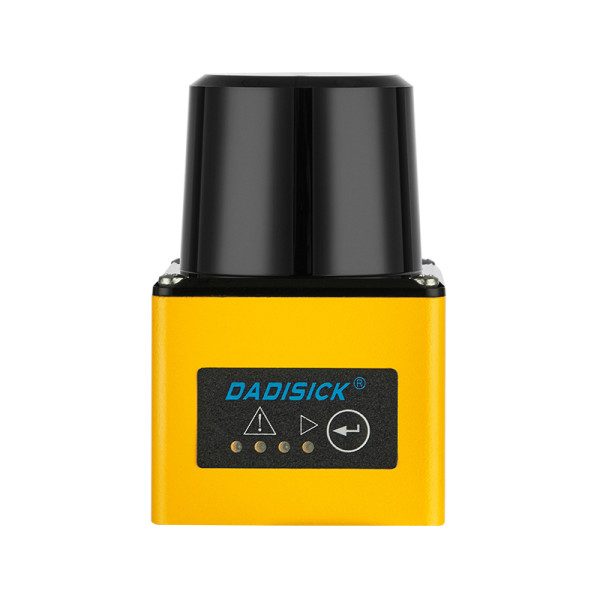

🔸2D LiDAR Scanner

2D LiDAR Scanner

Installation: Corners or perimeter of the workstation floor

Function: A 2D LiDAR scanner (e.g., SICK microScan3, Omron OS32C, Pilz PSENscan) creates configurable protection and warning zones. When a person or object enters the protection area, the system automatically slows or stops the robot.

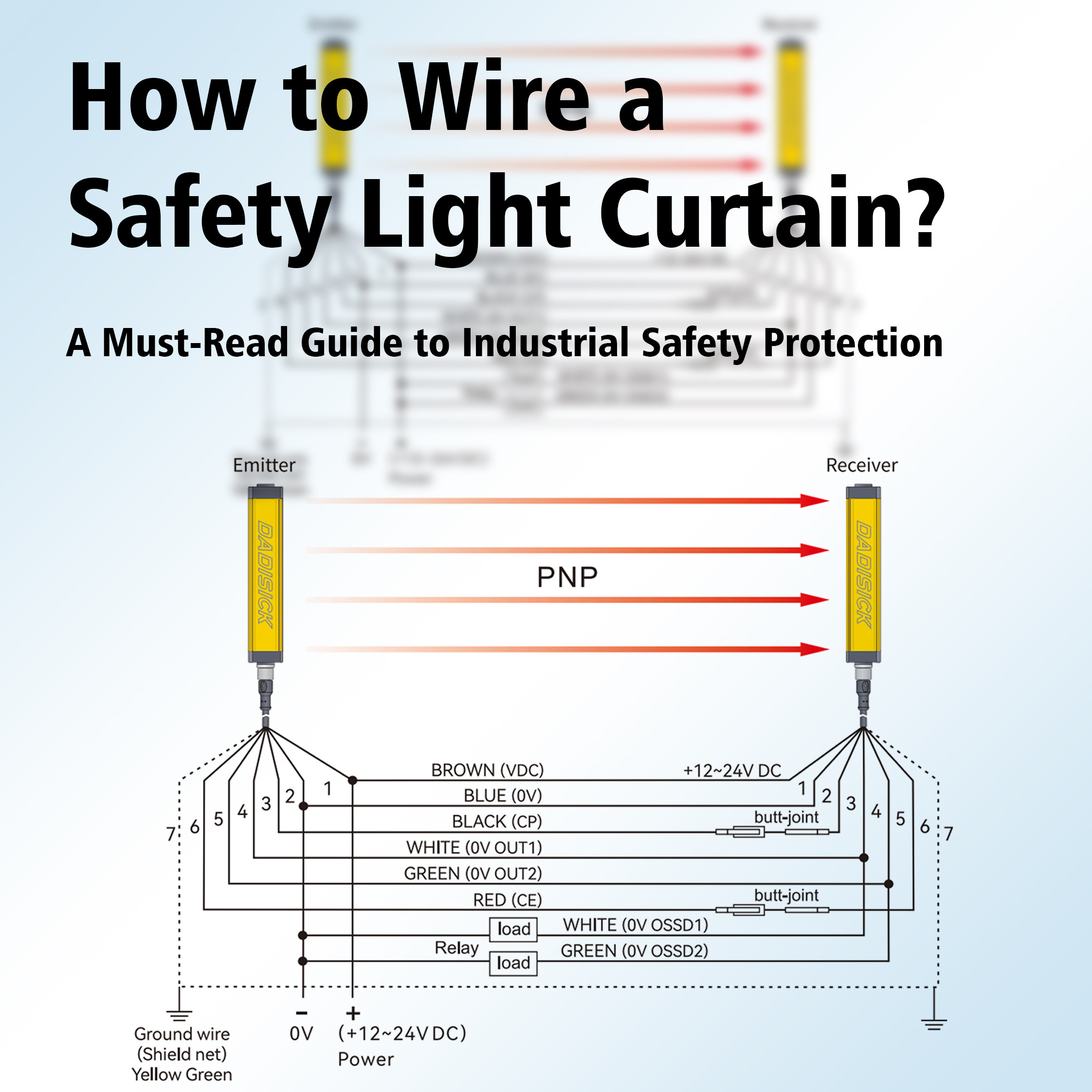

🔸 Safety Light Screen

Installation: At open passage points such as conveyor inlets or pallet exits

Function: The safety light screen (e.g., Schneider XUSL, SICK deTec, Banner EZ-SCREEN) detects body parts or personnel entering dangerous zones. Any signal interruption triggers an immediate robot stop, ensuring compliance with ISO 13849-1 and ISO 10218-1 standards.

🔸 Safety Switch for Door Monitoring

Installation: On access gates, maintenance doors, or fence panels

Function: A safety switch (e.g., ABB Eden, Omron D4NS, Pilz PSENmech) ensures the robot halts or cannot restart when the interlock gate is open. These safety interlock devices are crucial for door and panel protection.

🔸 E-Stop Buttons (Emergency Stop)

Installation: Easily accessible areas — control panels, fences, and walls

Function: Stop (E-stop) buttons enable operators to manually shut down the system immediately during emergencies, preventing injury or equipment damage.

🔸 Safety Relay

Installation: Control cabinet

Function: The safety relay or safety controller (e.g., Pilz PNOZmulti, Schneider Preventa, Omron G9SA) evaluates all input signals from safety devices such as light screens, safety switches, and pressure safety mats, ensuring correct logic control and machine shutdown when necessary.

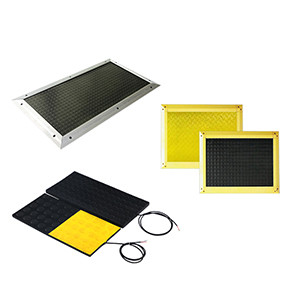

🔸 Industrial Safety Pressure Mats

Installation: Near manual load/unload areas or operator standing zones

Function: A pressure sensitive safety mat detects when an operator steps into a hazardous area. Once pressure is applied, the machine safety pressure mat sends a stop signal to the control system. These industrial safety mats (also known as pressure safety mats) are ideal for shared human-robot zones or collaborative robot setups.

Leading Manufacturer Practices in Robot Workstation Safety

🔹 SICK AG

• Provides advanced 2D LiDAR scanners like microScan3 for customizable safety zones

• Integrates light screens (deTec4) for precise finger and hand detection

• Offers powerful diagnostic tools via Safety Designer software

🔹 Schneider Electric

• The Preventa series connects safety switches, safety light screens, and safety relays in a modular system

• Enables plug-and-play integration for smarter safety devices architecture

🔹 Omron

• Compact 2D LiDAR scanners (OS32C) with 270° detection range

• Advanced safety relays (G9SP) suited for medium robotic cells

• Fully compatible with Sysmac automation platforms for easy integration

🔹 Pilz

• Comprehensive safety solutions with PSENscan, PSENmech, and PNOZmulti 2 controllers

• Focuses on TÜV-certified safe motion and modular logic configurations

🔹 ABB

• Provides SafeMove-enabled robot controllers for motion supervision

• Uses Eden safety switches for robust door monitoring

• Integrates seamlessly with safety PLCs and fieldbus communication systems

🔹 Banner Engineering

• Offers rugged and compact EZ-SCREEN light screens for small-to-medium robotic cells

• SC10 safety controller simplifies wiring and safety logic configuration

Typical Sensor Deployment in a Palletizing Robot Cell

1. 2D LiDAR scanners positioned at front-left and rear-right corners, each covering 270° zones

2. Safety light screens at pallet exits and conveyor entry points

3. Interlock gates with safety switches on every access door

4. Safety relay in the control cabinet managing all safety signals

5. E-stop buttons at each workstation corner for quick shutdown

6. Optional pressure sensitive safety mats in operator zones, especially for collaborative robot operations

Boosting Safety Without Compromising Efficiency

By combining intelligent zoning, restart interlocks, and dynamic muting, robotic systems can maintain high throughput while meeting ISO 10218-1 and ISO/TS 15066 safety standards. Modern safety devices offer diagnostic and predictive maintenance capabilities that minimize downtime and ensure long-term reliability.

A well-designed palletizing robot workstation integrates 2D LiDAR scanners, safety light screens, safety switches, safety relays, and industrial safety pressure mats into a unified control system — creating a safer, smarter, and more efficient production environment.

Related Safety Devices

Detection Method: Pressure sensing method

Maximum allowable load (8 hours) ≤ 400 N/cm²

Trigger Force: >20 kg

Surface Protection Material: NBR rubber

Mat Thickness: 15 mm

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Used for monitoring places such as safety doors and windows.

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

Similar Posts You May Be Interested in