Unlocking Precision: What Is a Laser Displacement Sensor? (Principle & Types) – DADISICK's Expert Guide

- Share

- publisher

- Zoe

- Issue Time

- Jul 31,2025

Summary

Discover how laser displacement sensors harness triangulation and confocal principles to deliver non-contact, µm-level accuracy. This guide breaks down the main sensor types, practical applications, and troubleshooting tips—while showcasing DADISICK’s GFL-G and GFL-Z series solutions for fast, reliable industrial measurement.

What Is a Laser Displacement Sensor? (Principle & Types)

A laser displacement sensor emits a laser beam toward a target and analyzes the returned light to determine distance, position, or dimensional thickness—without physical contact. Their µm-level accuracy, high speed, and versatility make them indispensable in automated manufacturing, quality control, robotics, and scientific research.

Laser Displacement Sensor Working

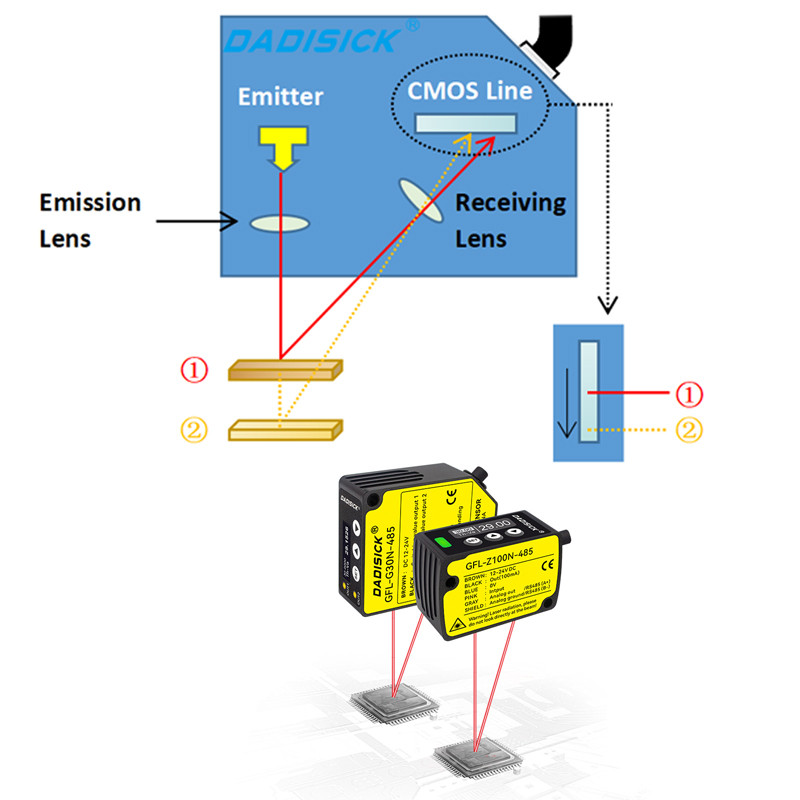

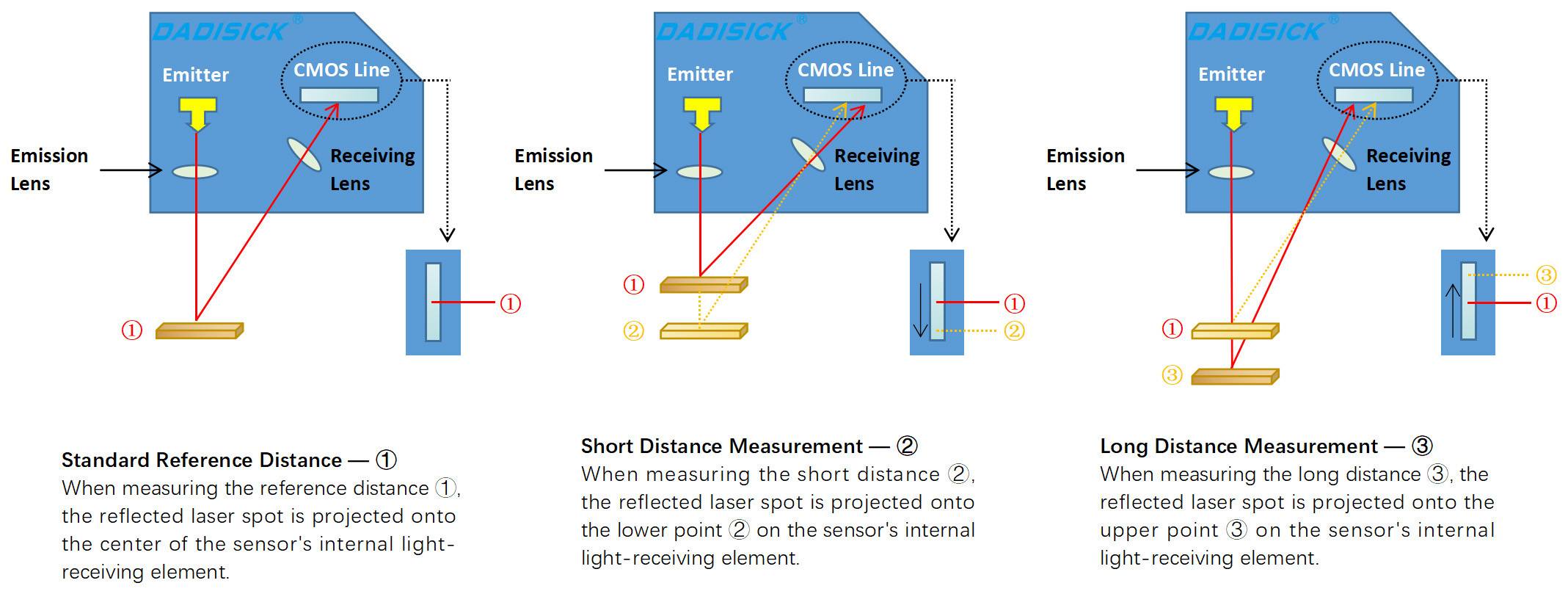

Laser Triangulation

How it works: A laser diode projects a beam onto the target. A lens collects the reflected light at a known angle and focuses it onto a position-sensitive detector (PSD, CMOS or CCD). As the target moves, the angle of reflection shifts, moving the light spot on the detector. The displacement is calculated from this spot shift using simple trigonometry.

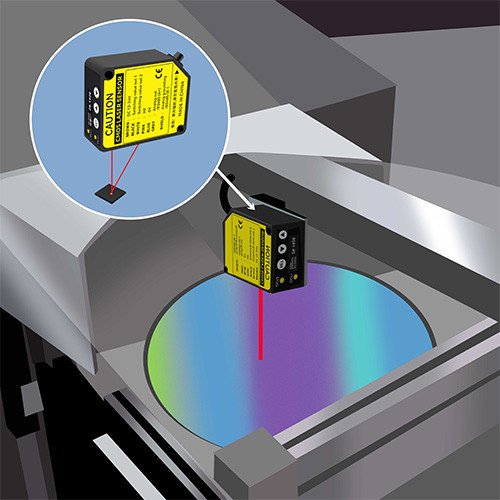

Confocal Principle

How it works: The sensor emits multi-wavelength (multi-color) laser light through a single axis (the transmitter and receiver share optics). Only the wavelength currently in focus returns enough intensity to pass through a pinhole; the sensor determines distance by detecting which color is in focus.

Types of Laser Displacement Sensors

| Sensor Type | Measurement Principle | Strengths | ||

| 1D Triangulation | Single-point spot & PSD/CMOS | High speed, compact heads, µm accuracy | ||

| Multi-Color Confocal | Axial chromatic focus variation | Stable on glossy/transparent surfaces, robust | ||

| Spectral Interference | Interferometry using spectral analysis | Ultra-high resolution, limited range | ||

2D/3D Laser Profiler | Line or plane scanning | Full cross-section or surface mapping | ||

•1D Triangulation: Ideal for fast, single-point height or thickness checks on flat or moving targets.

•Multi-Color Confocal: Best for transparent or highly reflective materials where triangulation struggles.

•Spectral Interference: Provides nm-level resolution for very short ranges (often <1 mm).

•Laser Profilers (2D/3D): Build line-scan or area-scan profiles for complex 3D inspections.

•Multi-Color Confocal: Best for transparent or highly reflective materials where triangulation struggles.

•Spectral Interference: Provides nm-level resolution for very short ranges (often <1 mm).

•Laser Profilers (2D/3D): Build line-scan or area-scan profiles for complex 3D inspections.

Why Choose a Laser Displacement Sensor?

•Non-Contact: Eliminates mechanical wear and avoids damaging delicate parts.

•High Precision & Repeatability: µm- or sub-µm resolution, with repeatability down to 0.005 µm in advanced models.

•Fast Response: Sampling rates up to hundreds of kHz for real-time control on high-speed lines.

•Versatile Integration: Multiple output protocols (analog, NPN/PNP switch, RS-485, Ethernet, IO-Link) and compact heads fit tight spaces and robot mounts

•Fast Response: Sampling rates up to hundreds of kHz for real-time control on high-speed lines.

•Versatile Integration: Multiple output protocols (analog, NPN/PNP switch, RS-485, Ethernet, IO-Link) and compact heads fit tight spaces and robot mounts

Find the right Laser Measurement Sensor for Your Application

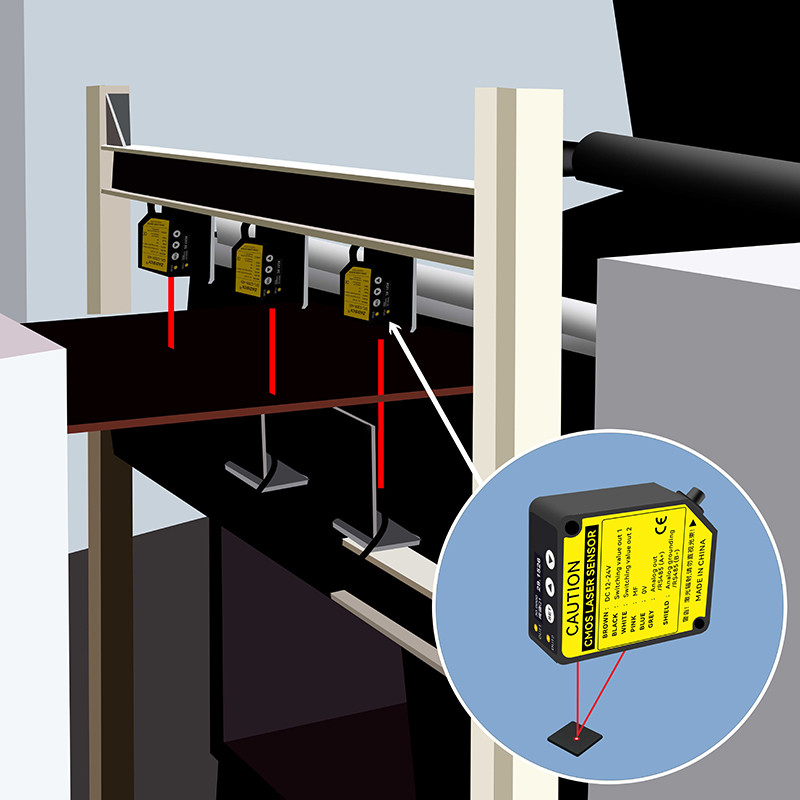

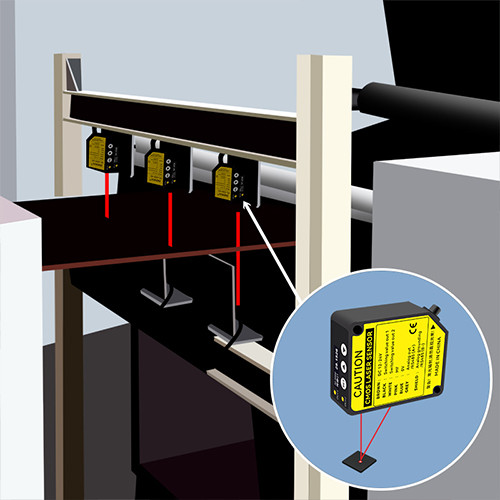

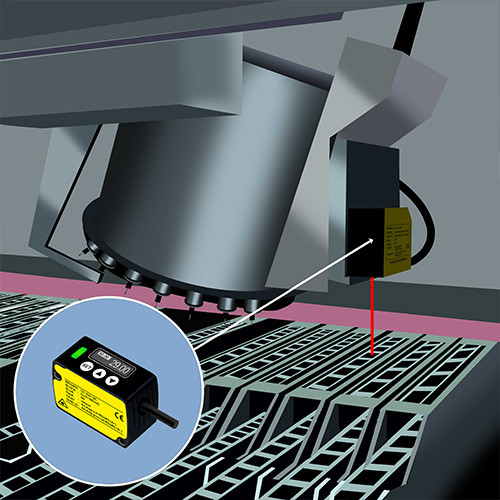

Thickness & Width Measurement

Used for detecting film, sheet, or strip materials to ensure dimensional consistency in real-time production.

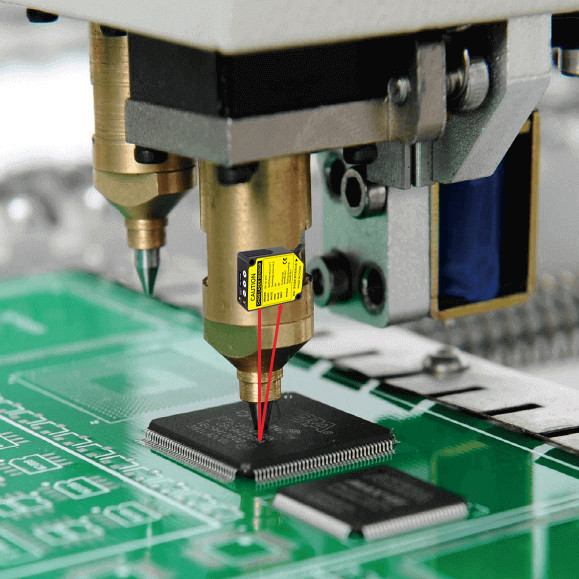

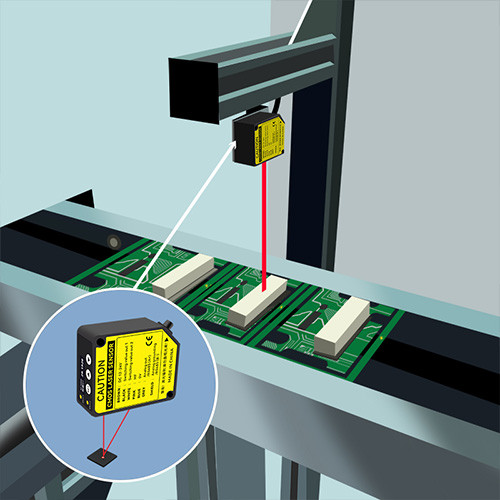

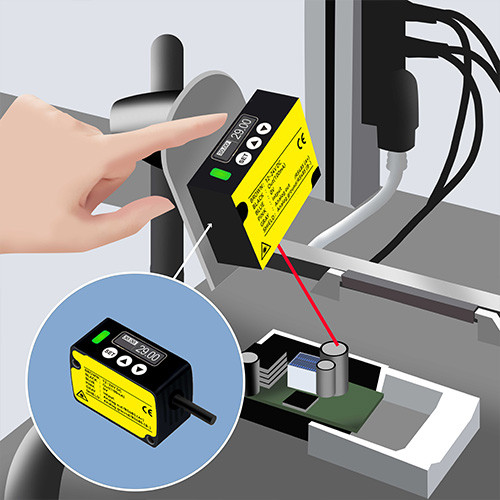

Height / Step Height Detection

Measures vertical steps or surface height differences in semiconductors, PCBs, or battery layers.

Inner & Outer Diameter

Accurately evaluates circular parts, such as shafts, tubes, or rings for diameter tolerance control.

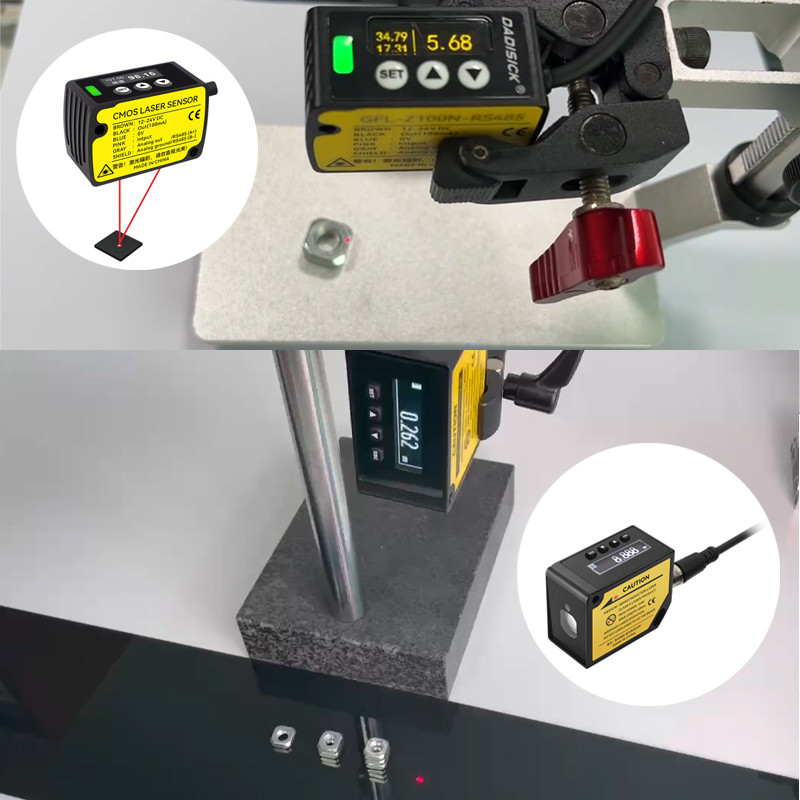

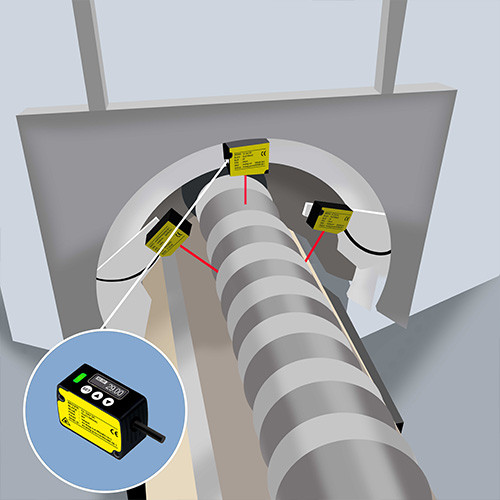

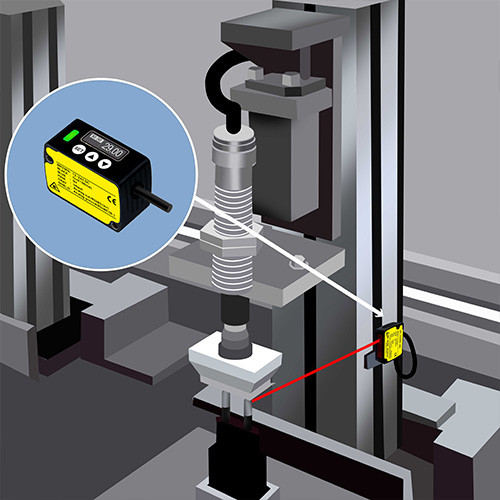

Vibration & Runout

Monitors dynamic motion of rotating machinery or precision parts to identify mechanical wear or imbalance.

Deflection & Eccentricity

Evaluates alignment errors and shaft center deviations during high-speed rotation or mechanical assembly.

2D Profile Measurement

Creates accurate cross-sectional scans of surfaces and edges, ideal for contour and geometry inspection.

Flatness & Warpage

Inspects large materials such as glass, metal sheets, or wafers for planarity and surface deformation.

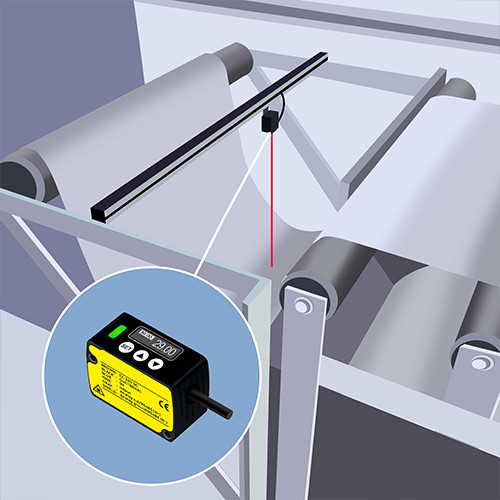

Meandering & Edge Detection

Tracks edge positions of thin materials like film or paper to prevent misalignment or edge drift.

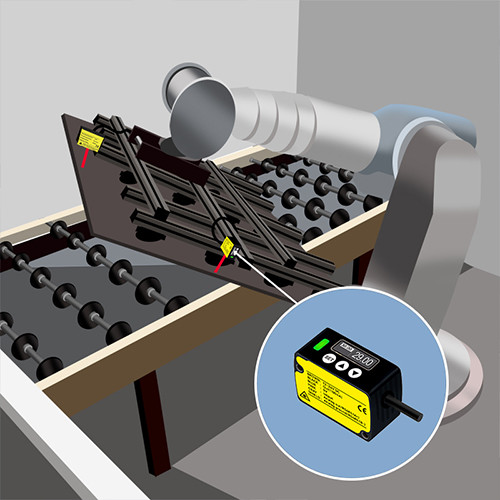

Positioning & Stroke Control

Supports precise positioning, multi-stage motion control, and automated movement feedback in machinery.

DADISICK's Laser Displacement Sensor Series

On our product page, you'll find two main families: