What is A Contact Type Displacement Sensor?

- Share

- publisher

- Zoe

- Issue Time

- Apr 25,2025

Summary

This article provides an in-depth explanation of the working principles, applications, and selection tips for contact displacement sensors, helping customers easily choose the right measurement solution for their needs.

What is A Contact Type Displacement Sensor?

Contact Displacement Sensors

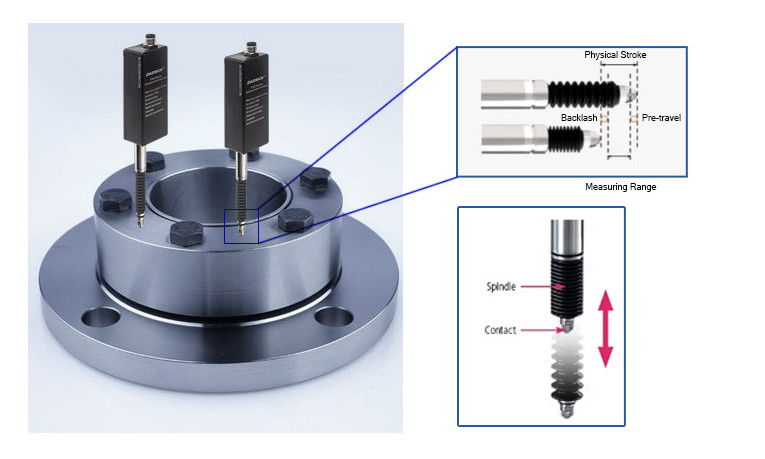

A contact-type displacement sensor is a precision instrument that measures the displacement or position of an object by making direct physical contact with it. Typically composed of a probe (stylus) and a sensor body, the probe contacts the object being measured, while the sensor body processes and outputs the displacement signal. These sensors are widely used in industrial automation, mechanical manufacturing, and electronic devices, particularly in applications requiring high precision and reliability.

How Do Contact Type Displacement Sensors Work?

Working Principle of Contact Displacement Sensors

1. Technical Principles

Contact displacement sensors function by detecting physical changes caused by the movement of a probe in contact with the target object. These changes are then converted into electrical signals for measurement. Common technical principles include:

• Resistive (e.g., Potentiometer): A sliding contact moves along a resistive track, causing a change in resistance that is proportional to the displacement, resulting in a corresponding voltage output.

• Inductive (e.g., LVDT): A ferromagnetic core moves within a coil, altering the inductance, which is then converted into a displacement measurement.

• Magnetoresistive: Utilizes the change in resistance of a material in response to an applied magnetic field, providing precise displacement measurements.

2. Typical Application Scenarios

Contact displacement sensors are widely used across various industries for precise measurement and control:

• Manufacturing: Monitoring tool displacement and ensuring dimensional accuracy in machining processes.

• Medical Devices: Controlling movements in surgical robots and adjusting positions in rehabilitation equipment.

• Automotive and Aerospace: Detecting displacement in engine components and positioning critical structures in aircraft.

• Construction Monitoring: Measuring displacement in bridge expansion joints and monitoring structural deformations.

How to Choose the Right Contact Displacement Sensor?

Key Points for Selecting Contact Displacement Sensors

1. Define Measurement Requirements

• Range and Accuracy: Choose a sensor specification based on the actual displacement range. For small displacements (micron level), an LVDT is suitable, while for larger displacements (millimeter level), a potentiometer type sensor is preferred.

• Resolution: High-precision applications (e.g., semiconductor processing) require sensors with nano-level resolution.

2. Environmental Adaptability

• Protection Rating: For environments with oil, vibration, or high temperatures, choose sensors with an IP67 or higher protection rating, such as magnetostrictive sensors.

• Anti-Interference Capability: In strong electromagnetic environments, shielded cables and grounding designs are necessary to avoid signal interference.

3. Installation and Maintenance

• Installation Method: Vertical installation can reduce errors, while a split design is suitable for complex spaces.

• Maintenance Cost: Choosing wear-resistant materials (e.g., conductive plastics) can extend lifespan and reduce replacement frequency.

4. Cost and Brand

• Within the budget range, prioritize high-cost-performance brands, such as Micro-Epsilon (Germany) for high precision and Keyence (Japan) for algorithm optimization.

Differences Between Contact Displacement Sensors and Non-Contact Displacement Sensors

| Comparison Dimension | Contact Displacement Sensors | Non-Contact Displacement Sensors | ||

| Measurement Method | Requires direct contact with the object | Indirect measurement via electromagnetic waves, laser, etc. | ||

| Accuracy and Stability | High precision (micron/nanometer level) | Sensitive to ambient light and surface material | ||

| Durability | Prone to wear, requires regular maintenance | Long lifespan (no physical contact) | ||

Applicable Scenarios | Precision machining, static or low-speed measurements | High-speed moving objects, detection of fragile surfaces | ||

Selection Principles for Contact Displacement Sensors and Non-Contact Displacement Sensors

• Core Requirement: When the measurement target involves dimensions, spacing, or positional accuracy, and there are no strict requirements for shape accuracy (e.g., the machining equipment has ensured shape conformity).

Advantages:

• Efficiency and Cost: Trigger-type sensors have compact probes, making them ideal for measurements in narrow spaces. Suitable for discrete point measurements (e.g., hole spacing, flatness).

• Typical Applications: Dimensional sampling in industrial production lines, tool positioning in machine tools, assembly position verification.

• Core Requirement: When the object being measured requires precise evaluation of shape, contour, or when machining equipment cannot ensure shape accuracy.

Advantages:

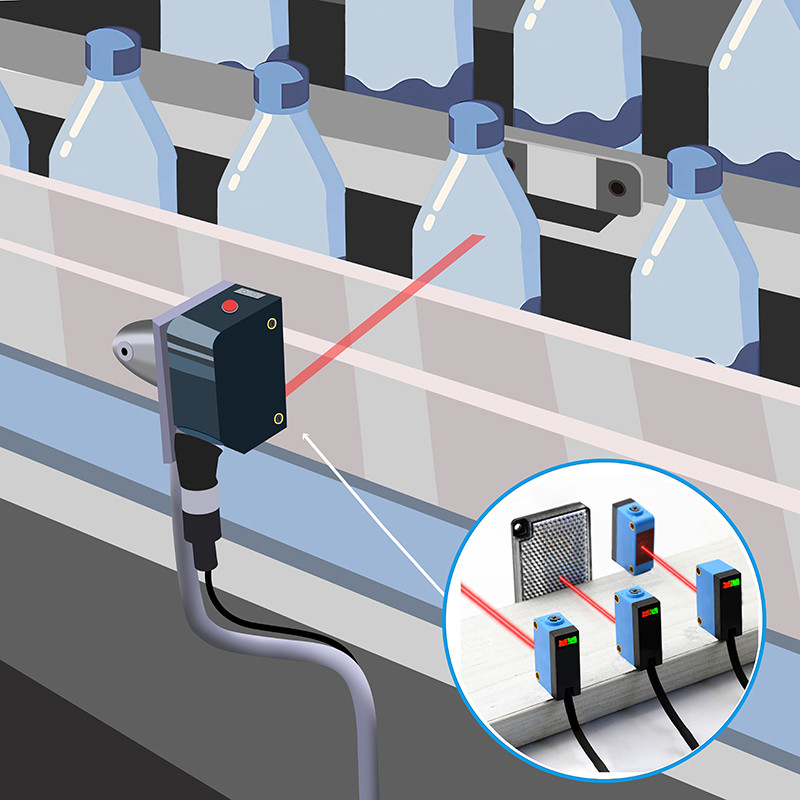

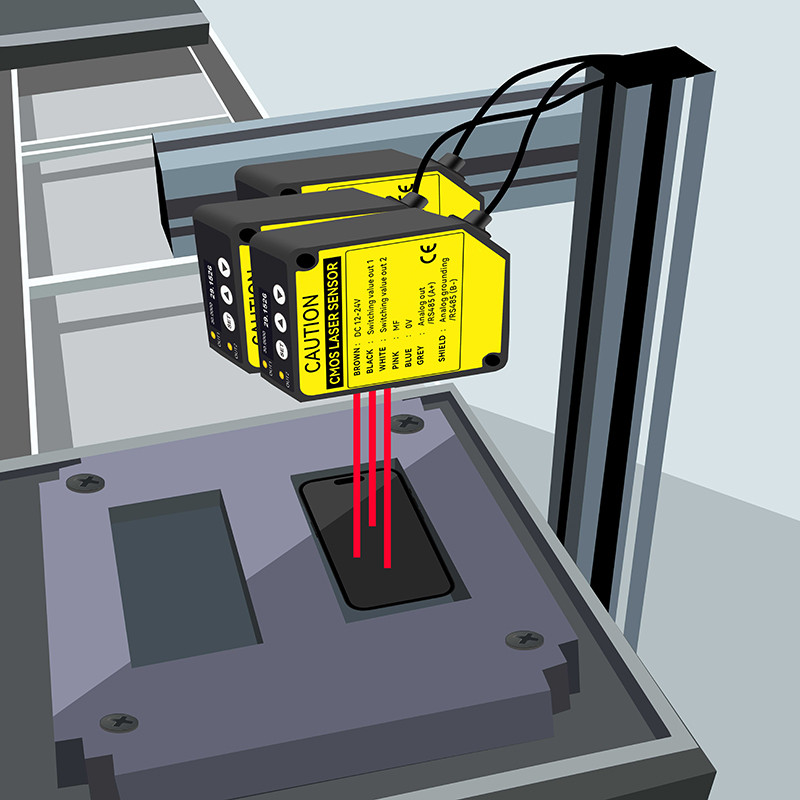

• Non-Destructive High-Speed Measurement: Using laser, optical, or eddy current technology, quickly obtaining dense point cloud data (e.g., laser displacement sensors).

• Non-contact measurement avoids damage to soft or delicate surfaces, with high-speed response (milliseconds) providing real-time feedback on machining deviations, supporting closed-loop control.

• Typical Applications: Laser displacement sensors are used to monitor machining precision (e.g., flatness, verticality, contour errors) in CNC machine tools, 3D printing, and semiconductor chip manufacturing.

Contact displacement sensors play an indispensable role in various industries due to their high precision and reliability. When selecting the appropriate sensor, factors such as measurement range, accuracy requirements, environmental conditions, installation method, and budget must be considered comprehensively to ensure that the sensor meets the actual application needs.

Related Displacement Sensors

Range: 10mm(±5mm)

Repeat accuracy: < 1μm

Linearity: ±0.4% F.S

Measurement force: min 0.2N

Measuring range: 0-12.7 mm

Resolution: 0.2μm

Accuracy: ≤1.4μm

Response time: 50ms

Response time: up to 1.0ms

Repetitive accuracy: up to 2µm

Response time: up to 1.5ms

Repetitive accuracy: up to 10µm