DADISICK Safety Light Curtain Series Comparison Guide

- Share

- Issue Time

- Feb 7,2026

Summary

Explore a comprehensive comparison of all DADISICK safety light curtain series by structure, coverage logic, installation types, and environment criteria to help engineers select the right industrial safeguarding solution.

A Practical Overview of Safety Light Curtain Types and Selection Logic

Safety light curtains are a critical component of industrial machine safeguarding.

However, selecting the correct series requires more than comparing prices or basic specifications—it demands a clear understanding of structural design, protection logic, installation constraints, and operating environment.

This article provides a systematic comparison of all DADISICK safety light curtain series, helping engineers, system integrators, and machine builders quickly identify the most suitable solution for their application.

Why Comparing Safety Light Curtain Series Matters

Different safety light curtain series are designed to solve different engineering problems, such as:

· Limited installation space

· Large or tall protection areas

· Multi-directional access

· Harsh or wet environments

· Budget-sensitive projects

Using an inappropriate series can lead to:

· Over-engineering and unnecessary cost

· Installation conflicts

· Incomplete access protection

A structured comparison ensures effective protection without excessive complexity.

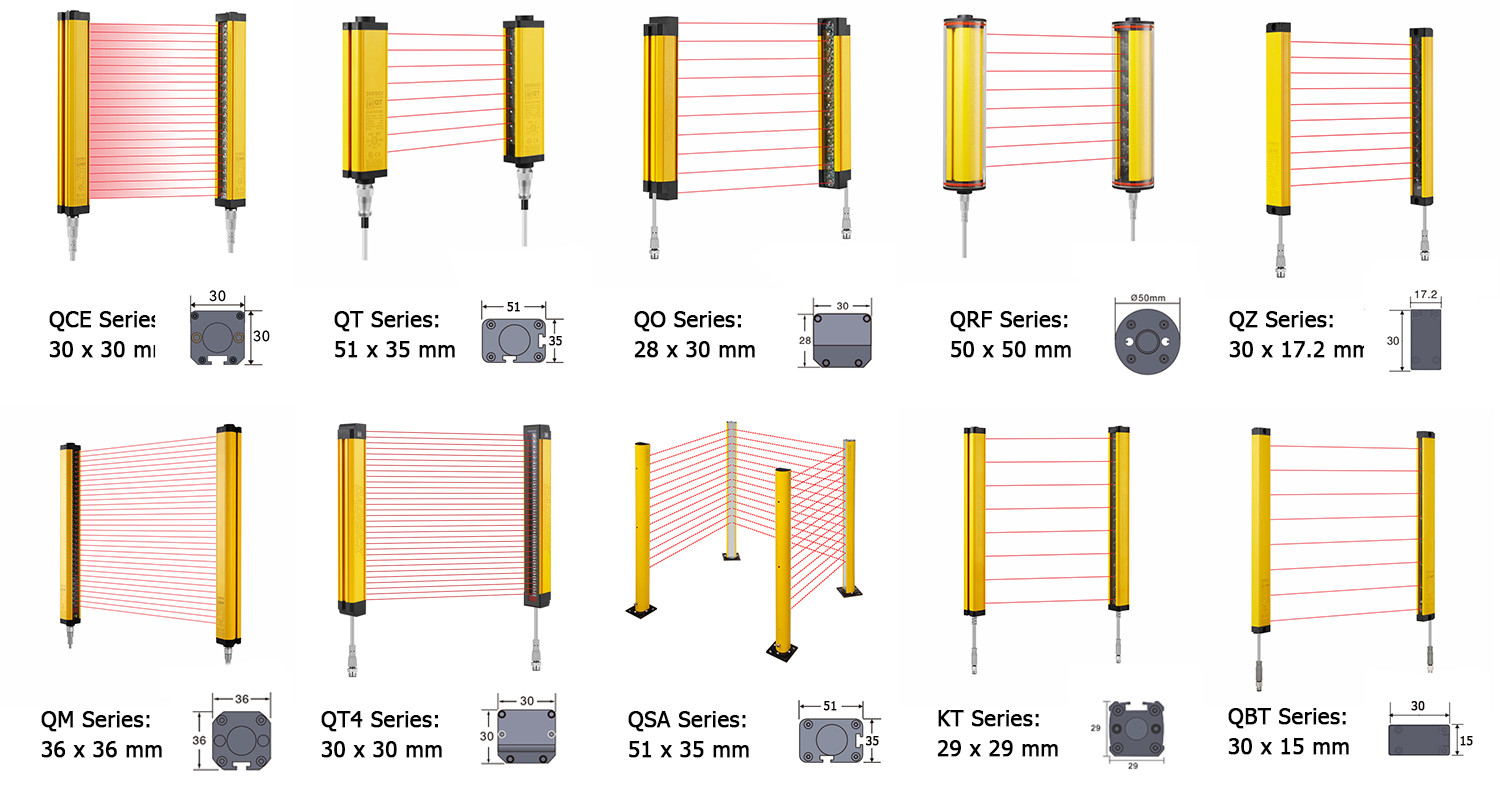

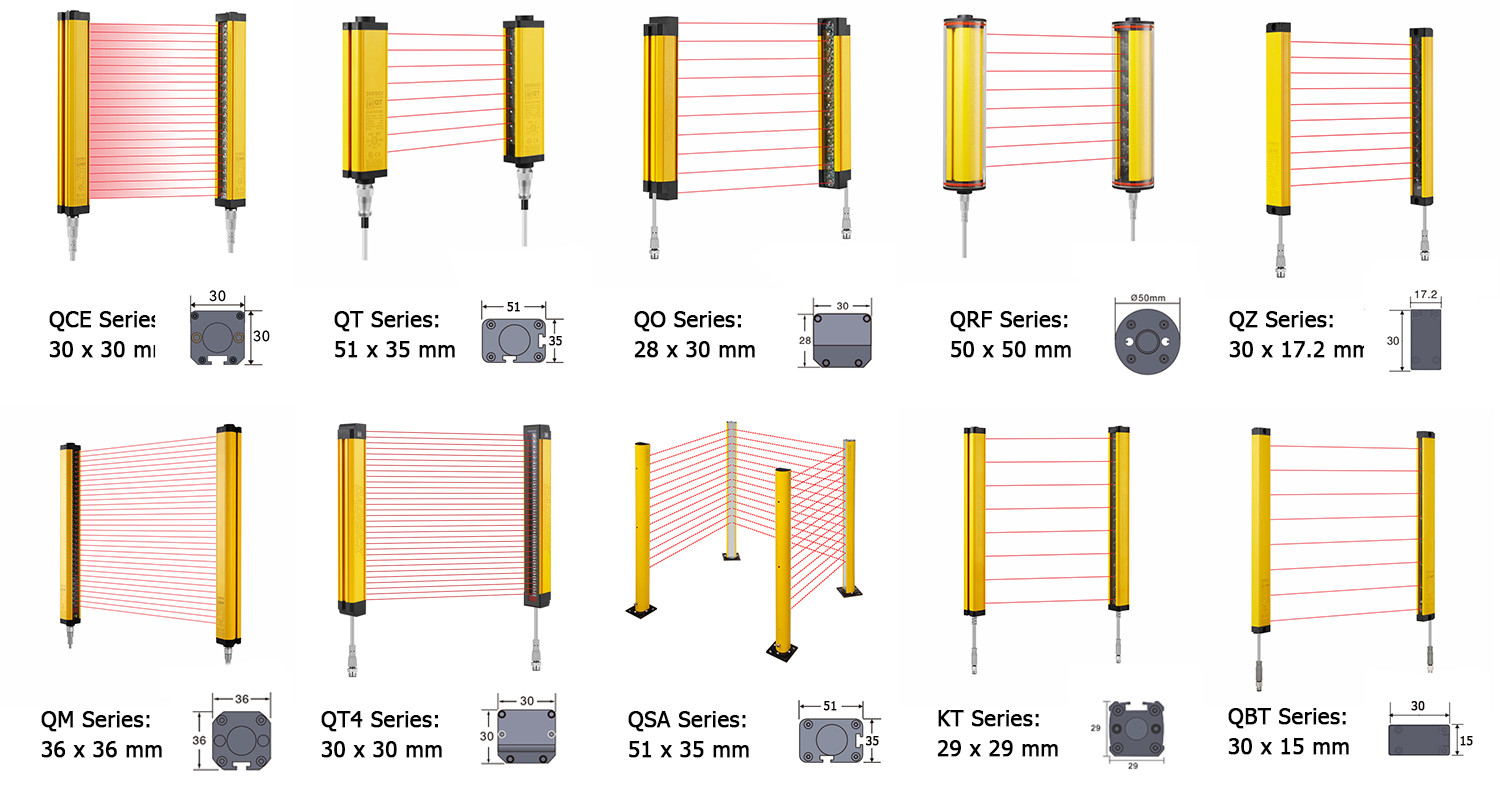

Overview of DADISICK Safety Light Curtain Portfolio

DADISICK offers 10 distinct safety light curtain series, each optimized for specific functional and installation requirements.

Rather than listing products individually, the following table compares the series based on official product positioning and real-world application characteristics.

Safety Light Curtain Series Functional Comparison

Series | Official Positioning | Core Technical Feature | Installation Advantage | Protection Logic | Typical Application |

| QCE | General-purpose | Balanced optical and mechanical design | Standard mounting | Single-plane access protection | Presses, standard automation machines |

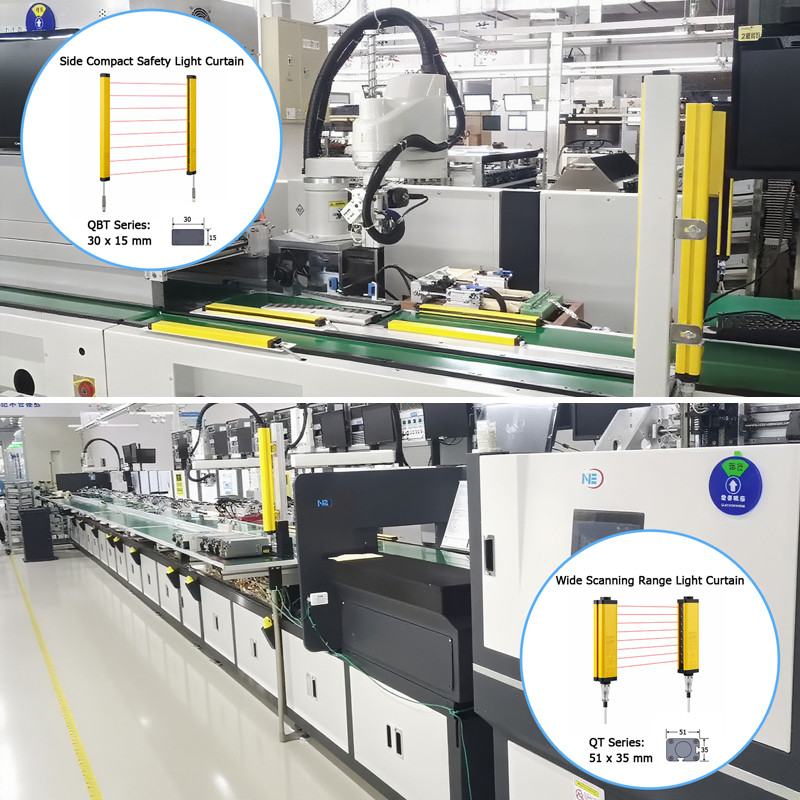

| QT | Wide scanning range | Extended detection distance and span | Covers large openings | Wide-area presence detection | Conveyors, logistics lines |

| QO | Eliminating dead zones | Optimized beam layout without blind spots | Full opening coverage | Continuous detection | High-risk access points |

| QT4 | Cascade safety light curtain | Cascaded connection for extended height | Vertical expansion | Tall-area safeguarding | Robotic cells, tall machinery |

QRF | Waterproof safety light curtain | Sealed housing for moisture resistance | Washdown-compatible | Standard access protection | Food, beverage, outdoor equipment |

KT | Economical safety light curtain | Simplified, cost-optimized structure | Easy integration | Basic safety protection | Cost-sensitive machines |

QBT | Side-compact safety light curtain | Narrow side profile | Fits limited side space | Standard access protection | Compact machine frames |

QZ | Front ultra-thin safety light curtain | Slim front-facing structure | Minimal front intrusion | Opening protection | Small machine openings |

QM | Standard safety light curtain | Flexible configuration | Versatile mounting | General-purpose protection | Multi-industry applications |

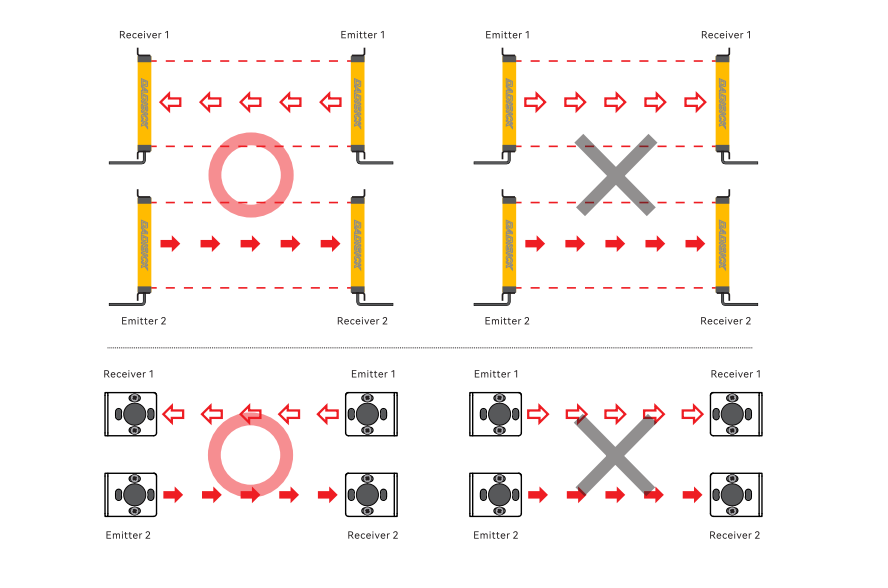

QSA | Multi-sided access protection | Multi-directional detection layout | Enclosure-level coverage | Multi-access safeguarding | Robotic cells, fenced areas |

Functional Classification of Safety Light Curtain Series

To simplify selection, the series can be classified by functional nature.

1. Classification by Structural Design

· Ultra-compact designs:

QBT (side-compact), QZ (front ultra-thin)

· Standard structural designs:

QCE, QM, KT, QO, QRF

· Expandable or modular structures:

QT4 (cascade configuration)

2. Classification by Protection Coverage Logic

· Single-plane access protection:

QCE, KT, QM, QBT, QZ, QRF

· Wide-area or long-distance protection:

QT

· Dead-zone elimination:

QO

· Vertical extended protection:

QT4

· Multi-directional access protection:

QSA

3. Classification by Operating Environment

· Standard industrial environments:

QCE, QT, QO, QT4, KT, QBT, QZ, QM, QSA

· Harsh or wet environments:

QRF

Practical Selection Logic for Engineers

In real machine safeguarding projects, engineers typically follow this decision path:

1. Define access direction and protection height

2. Evaluate installation space constraints

3. Assess environmental exposure (water, dust, cleaning)

4. Balance safety requirements and project budget

The optimal solution is the series that meets safety requirements precisely—without unnecessary over-specification.

Common Misunderstandings About Safety Light Curtain Selection

"A higher-end series always provides better safety."

Safety performance depends on correct application, not series complexity.

"All safety light curtains are interchangeable."

Differences in structure and detection logic directly affect protection effectiveness.

"Compact designs reduce safety performance."

Compact series optimizes form factor while maintaining required safety functions.

Frequently Asked Questions (FAQ)

Q1: Are all DADISICK safety light curtain series suitable for industrial safety applications?

Yes. Each series is designed for industrial machine safeguarding when properly selected and installed.

Q2: Which series is recommended for machines with limited installation space?

QBT and QZ are optimized for side-limited and front-limited installations.

Q3: Which series should be used for multi-directional access protection?

QSA is specifically designed for multi-sided and enclosed access areas.

Q4: Which series supports extended protection height?

QT4 uses a cascade structure to achieve extended vertical coverage.

Official Technical Statement

This article provides general, application-oriented information on the functional differences among the safety light curtain series.

Final risk assessment, product selection, system integration, and compliance verification must be carried out by qualified safety professionals in accordance with applicable standards and local regulations.

Conclusion

Understanding the functional differences among the safety light curtain series is essential for effective machine safeguarding.

By comparing structure, protection logic, installation constraints, and environment suitability, engineers can confidently select the most appropriate solution for their application.

Related Safety Devices

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 2.5mm

Number of optical axes: 160

Protection height: 397.5mm

Safety Curtain outputs (OSSD):2 PNP

Beam spacing: 20mm

Number of optical axes: 106

Protection height: 2100mm

Safety curtain outputs (OSSD): 2 PNP

Beam spacing:10mm

Number of optical axes: 20

Protection height: 190mm

Safety Curtain outputs (OSSD):2 PNP

Similar Posts You May Be Interested in