Top 10 Global Safety Light Curtain Manufacturers

- Share

- Issue Time

- Dec 27,2025

Summary

Safety light curtains play a critical role in machine safeguarding across modern manufacturing. This article introduces the top 10 global safety light curtain manufacturers, comparing their company background, technical strengths, and typical application scenarios. It also explains how users can evaluate suitable solutions based on real industrial needs, including a practical overview of DADISICK safety light curtain solutions.

Why Safety Light Curtain Manufacturers Matter

Safety light curtains are widely used to protect operators from hazardous machine movements while maintaining productivity. However, selecting the right solution often depends not only on technical specifications, but also on the manufacturer's design philosophy, industry focus, and application experience.

This article provides a structured overview of the top 10 global safety light curtain manufacturers, helping engineers, system integrators, and procurement professionals better understand market positioning and selection criteria.

DADISICK – Practical and Flexible Safety Light Curtain Solutions for Machine Safety

Company Profile

Core Strengths

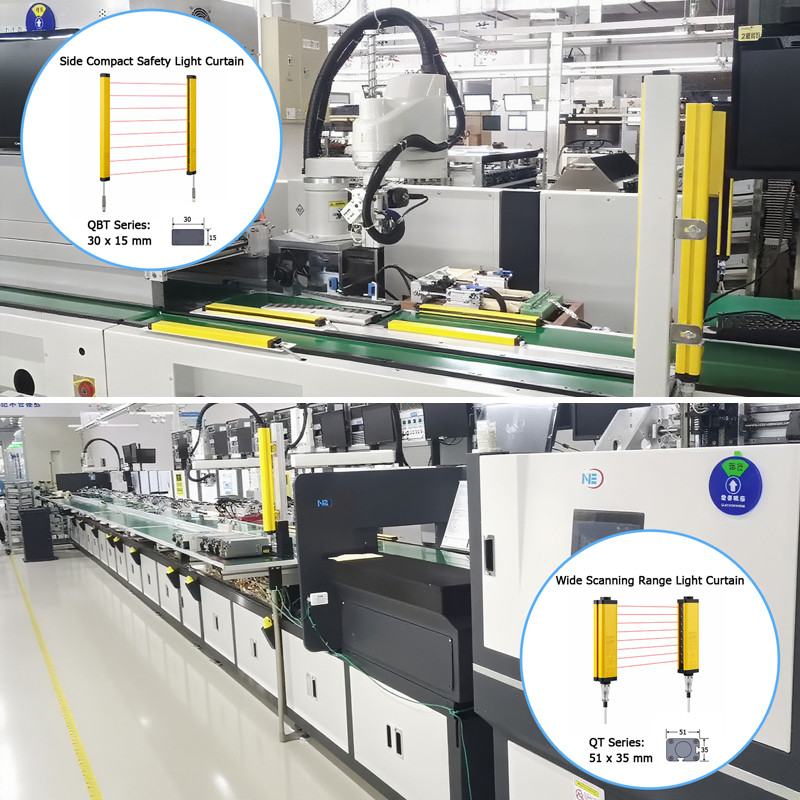

DADISICK safety light curtains are engineered to balance performance, flexibility, and cost efficiency. The product range offers multiple detection resolutions, protective heights, and wide scanning options while complying with international safety standards, making them adaptable to diverse machine types.

Typical Applications

DADISICK solutions are widely used in press machines, laser cutting equipment, automated assembly lines, and packaging machinery. For application-oriented machine protection, DADISICK safety light curtain solutions

provide a practical and reliable choice.

Keyence Corporation – High-Performance Safety Light Curtains for Precision Automation

Company Profile

Core Strengths

Keyence safety light curtains are designed with high optical power and fast response times, ensuring stable detection even in high-speed or vibration-prone environments. Built-in diagnostics, alignment assistance, and user-friendly setup tools help reduce commissioning time and ongoing maintenance complexity.

Typical Applications

These products are commonly used in automotive body lines, lithium battery manufacturing, precision electronics assembly, and high-speed packaging systems where accuracy, uptime, and detection reliability are critical.

SICK AG – Comprehensive Type 2 and Type 4 Safety Light Curtain Solutions

Company Profile

Core Strengths

SICK offers one of the broadest safety light curtain portfolios on the market, covering Type 2 and Type 4 devices with advanced functions such as muting, blanking, cascading, and long-range protection. Its products are often selected for complex safety architectures requiring high configurability and strict compliance.

Typical Applications

SICK safety light curtains are extensively applied in robotic cells, automated material handling systems, palletizing stations, and logistics facilities where multiple hazards must be managed simultaneously.

Omron Corporation – Integrated Safety Light Curtains for Automated Production Lines

Company Profile

Core Strengths

Omron safety light curtains emphasize long-term stability, standardized design, and system-level integration. They are particularly valued in environments where safety devices must communicate smoothly with safety PLCs and control systems over extended operational lifecycles.

Typical Applications

Typical use cases include general manufacturing lines, standardized assembly systems, food and beverage equipment, and production environments prioritizing consistency and lifecycle reliability.

Rockwell Automation (Allen-Bradley) – Safety Light Curtains for Standardized Industrial Systems

Company Profile

Core Strengths

The primary advantage of Rockwell safety light curtains lies in deep integration with Rockwell safety controllers, enabling centralized configuration, diagnostics, and safety management. This reduces system complexity in plants that standardize on Rockwell platforms.

Typical Applications

These solutions are frequently used in automotive manufacturing, heavy industrial machinery, and large-scale production facilities with standardized automation architectures.

Banner Engineering – Flexible Safety Light Curtains for OEM and Packaging Machinery

Company Profile

Core Strengths

Banner safety light curtains focus on ease of installation, robust mechanical construction, and flexible mounting options. These characteristics make them well-suited for OEMs and system integrators seeking quick deployment and minimal setup complexity.

Typical Applications

They are commonly found in packaging machinery, material handling equipment, conveyor systems, and mid-speed automated machines.

Leuze electronic GmbH – Intelligent Safety Light Curtains with Advanced Diagnostics

Company Profile

Core Strengths

Leuze safety light curtains feature high detection precision combined with advanced diagnostic and communication capabilities. This allows operators to monitor system status, identify alignment issues, and support predictive maintenance strategies.

Typical Applications

Typical applications include smart factories, intralogistics systems, automated warehouses, and production lines requiring high transparency and digital connectivity.

Panasonic Industry – Compact Safety Light Curtains for Precision Equipment

Company Profile

Core Strengths

Panasonic safety light curtains emphasize compact form factors, stable optical performance, and consistent production quality. Their designs are well-suited for equipment where space is limited but reliable detection is essential.

Typical Applications

They are often used in electronics assembly equipment, semiconductor-related machinery, and compact automated systems.

Schneider Electric – Industrial Safety Light Curtains for Global Automation Projects

Company Profile

Core Strengths

Schneider's safety light curtains are designed to integrate into standardized automation platforms, supporting global compliance, lifecycle management, and unified safety strategies across multiple sites.

Typical Applications

They are commonly applied in large industrial projects, standardized production lines, and facilities operating across multiple regions.

IDEC Corporation – Cost-Effective Safety Light Curtains for Basic Machine Protection

Company Profile

Core Strengths

IDEC safety light curtains provide essential machine safeguarding functions while maintaining affordability. They are suitable for applications where basic protection is required without advanced customization.

Typical Applications

Commonly used in small and medium-sized machines, retrofit projects, and cost-sensitive industrial environments.

Comparison Table: Top 10 Safety Light Curtain Manufacturers

| Manufacturer | Country | Product Positioning | Core Strength Focus | Typical Industries |

DADISICK | China | Practical & flexible | Multiple resolutions, wide scanning range, cost-performance balance | Presses, laser cutting, assembly lines |

Keyence | Japan | High-end / Premium | High optical power, fast response, ease of setup | Automotive, electronics, battery |

Omron | Japan | Integrated automation | System compatibility, lifecycle stability | General manufacturing, food processing |

Rockwell (Allen-Bradley) | USA | Platform-oriented | Deep PLC integration, centralized diagnostics | Automotive, heavy industry |

Banner Engineering | USA | Practical / OEM-focused | Easy installation, robust design | Packaging, conveyors, OEM machines |

| Leuze | Germany | Intelligent safety | Advanced diagnostics, digital communication | Smart factories, intralogistics |

SICK | Germany | Full-range / Industrial-grade | Broad Type 2 & Type 4 portfolio, advanced functions | Robotics, logistics, material handling |

| Panasonic Industry | Japan | Compact & precise | Space-saving design, stable detection | Electronics, semiconductor equipment |

| Schneider Electric | France | Standardized global solutions | Platform integration, global compliance | Multinational manufacturing |

IDEC | Japan | Cost-effective | Basic safeguarding, affordability | Small & medium machines |

Frequently Asked Questions (FAQ)

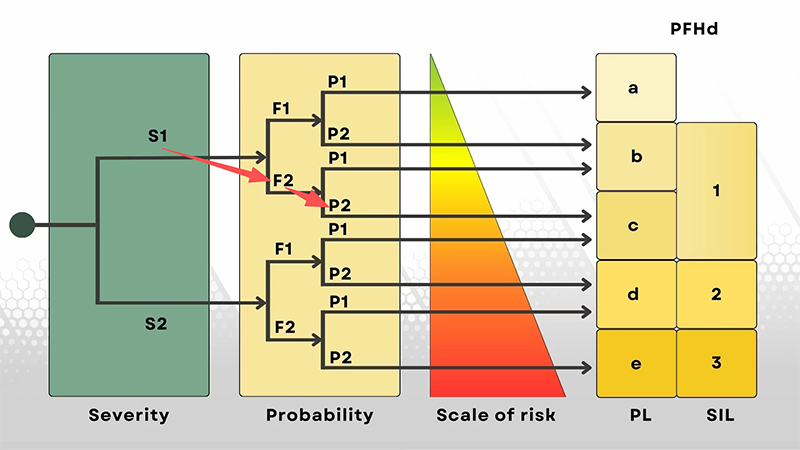

What is the difference between Type 2 and Type 4 safety light curtains?

Type 2 safety light curtains are designed for lower-risk applications where the probability of injury is relatively low and additional risk reduction measures may be present. Type 4 safety light curtains, on the other hand, are intended for high-risk machinery and hazardous environments, offering higher fault tolerance and stricter safety performance. The choice depends on risk assessment results and applicable safety standards.

How do I choose the right safety light curtain manufacturer for my machine?

Selecting a safety light curtain manufacturer should be based on application requirements rather than brand popularity alone. Key factors include required safety level, detection resolution, protective height, installation distance, integration with control systems, and budget constraints. Manufacturers like DADISICK are often selected for application-driven projects where flexibility and cost-performance balance are important.

Are expensive safety light curtains always safer or better?

Not necessarily. Higher-priced safety light curtains often provide advanced diagnostics, premium materials, or brand-related service advantages. However, for many standard applications, mid-range solutions that comply with international safety standards can deliver reliable protection without unnecessary cost. Proper specification matching is more important than price alone.

Can safety light curtains be used on different types of machines?

Yes. Safety light curtains are widely used on press machines, laser cutting equipment, packaging machinery, automated assembly lines, robotic cells, and material handling systems. The key is selecting the correct detection resolution, protective height, and mounting distance based on the specific machine hazard.

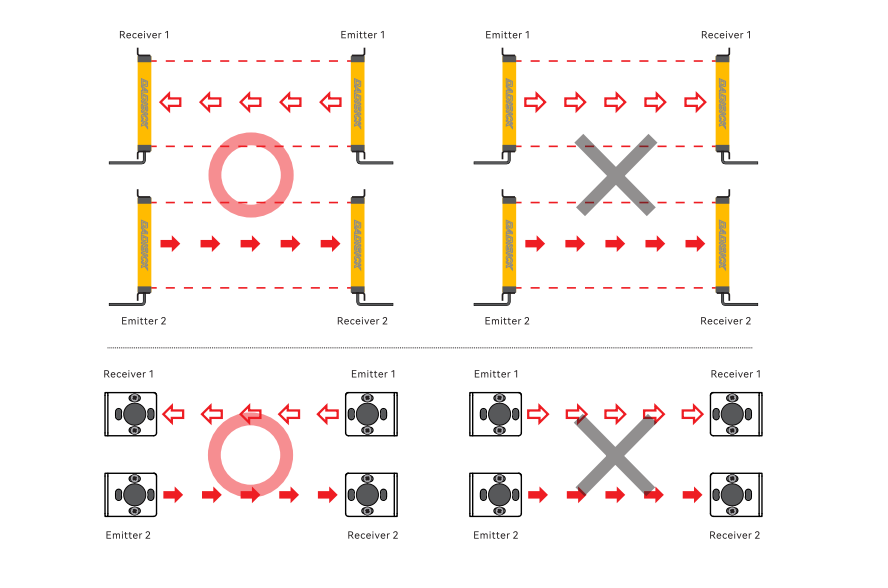

When is a wide scanning range safety light curtain recommended?

Wide scanning range safety light curtains are recommended for applications with large openings or long protection distances, such as conveyors, palletizers, or large automated equipment. In these cases, using a wide scanning range solution—such as DADISICK wide scanning range safety light curtains—can reduce the need for multiple units while maintaining stable detection.

Do safety light curtains require regular maintenance?

Safety light curtains generally require minimal maintenance, but periodic inspection is recommended. This includes checking alignment, cleaning optical surfaces, verifying wiring integrity, and performing functional tests according to the machine safety plan. Proper installation and stable mounting significantly reduce long-term maintenance needs.

Conclusion

The global safety light curtain market includes both long-established brands and specialized manufacturers. Understanding each supplier's strengths and application focus allows engineers and decision-makers to select solutions that meet real-world requirements.

For projects requiring flexible configurations and practical safeguarding solutions, DADISICK represents a reliable and application-focused option.

Related Safety Devices

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Beam spacing: 20mm

Number of optical axes: 10

Protection height: 180mm

Security light curtain outputs (OSSD)2 PNP

Beam spacing: 2.5mm

Number of optical axes: 32

Protection height: 77.5mm

Beam spacing:200mm

Number of optical axes: 4

Protection height: 600mm

Safety Curtain outputs (OSSD):2 PNP

Similar Posts You May Be Interested in