Safety Light Curtain Terminology Explained: A Practical Guide for Machine Safety Design

- Share

- Issue Time

- Dec 19,2025

Summary

This article explains the most important professional terms used in safety light curtains, including beam pitch, resolution, protective height, safety distance calculation, and fail-safe logic. A practical guide for engineers, machine builders, and safety managers using industrial safety light curtains.

Safety light curtains are widely used in industrial automation to protect operators from hazardous machine movements. However, many users misunderstand key technical terms such as resolution, beam pitch, or safety distance, which may lead to incorrect installation or reduced protection.

This article provides a clear explanation of the most common safety light curtain professional terms, helping engineers, system integrators, and purchasing teams make safer and more informed decisions. As a manufacturer specializing in industrial machine safety solutions, DADISICK focuses on providing certified safety light curtains, safety relays, and protective devices for global automation applications.

Core Terminology of Safety Light Curtains

Optical Beam (Infrared Beam)

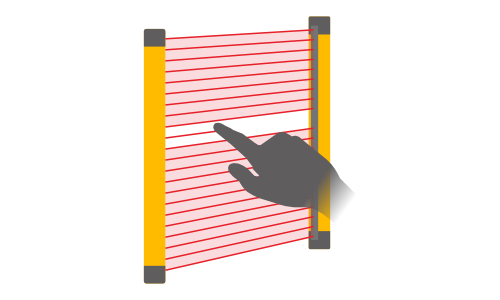

A safety light curtain emits infrared beams at a fixed frequency from the transmitter. After passing through the optical system, these beams form a parallel detection field that is received by the receiver. When any beam is interrupted, the system immediately sends a safety stop signal. Engineers can choose from a variety of industrial safety light curtains offered by DADISICK to meet their specific application requirements.

Beam Pitch (Optical Axis Distance)

Beam pitch refers to the center-to-center distance between two adjacent infrared beams.

Typical values include:

· Smaller pitch (e.g., 10–20 mm) enables detection of fingers or hands.

· A larger pitch (e.g., 30–40 mm) is suitable for detecting body or limb intrusion but may not catch smaller objects.

· Resolution (object detection size) is typically equal to beam pitch or slightly larger due to optical design tolerances.

Selecting the correct beam pitch and resolution is essential for matching the application's hazard profile. For high-risk areas requiring fine object detection (e.g., finger detection on automated presses), choose light curtains with a smaller beam pitch. For large body detection around robot cages, a larger pitch may suffice and simplify wiring distance requirements.

Resolution (Detection Capability)

· Higher resolution = better detection precision

· Smaller resolution values are typically used for finger or hand protection

Resolution directly affects the calculation of safety distance and the suitability of application.

Finger protection

Detection capability

10mm

diameter

Hand protection

Detection capability

20/30/40mm

diameter

Arm/body protection

Detection capability

80/200mm

diameter

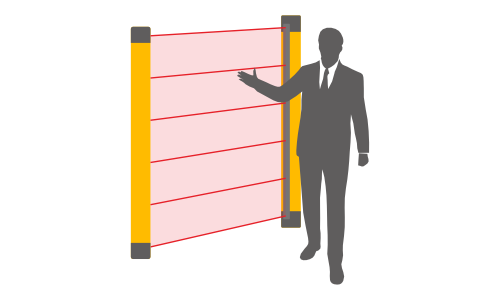

Protective Height (Effective Detection Height)

Protective height refers to the effective vertical detection area of the light curtain. It is usually measured from the first beam to the last beam center. Selecting an appropriate protective height ensures full coverage of the hazardous area.

Precautions for determining the protection height

· Protective height must cover all possible ingress points where a human may reach the hazard.

· If the protective height is too short, operators might bypass the detection zone by bending or reaching above/below it.

· Selecting protective height requires a risk assessment of operator reach range, workpiece handling height, and machine geometry.

In complex machinery with multiple access levels, engineers might use multiple staggered light curtains or combine them with physical barriers to ensure complete vertical coverage.

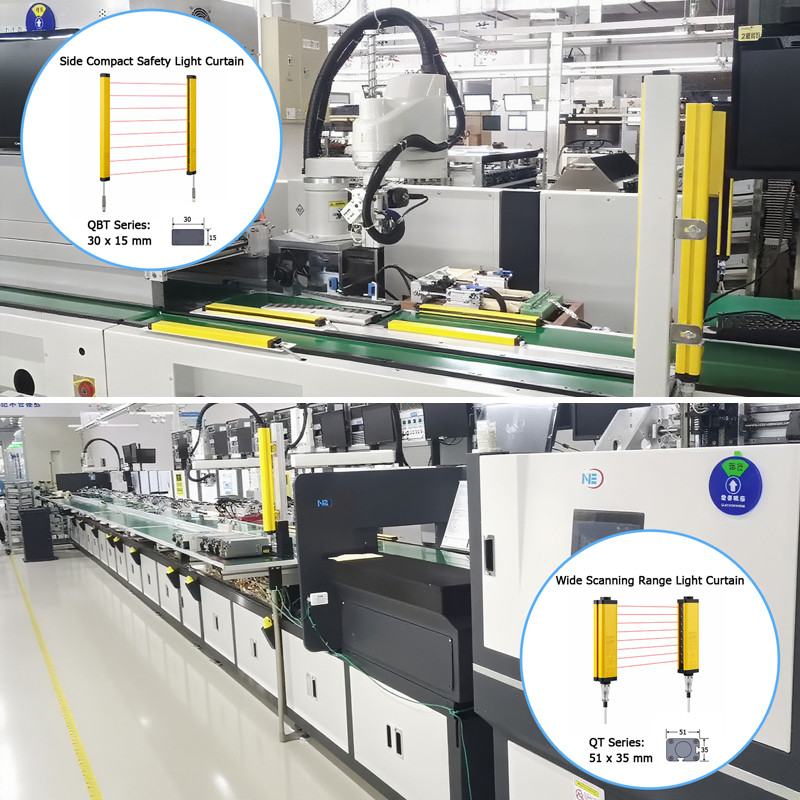

Protective Length — Horizontal Detection Range and Scanning Width

Protective Length and Its Role in Monitoring Wide Hazard Openings

· Protective length determines how wide a hazard opening can be monitored by a light curtain.

· Longer protective length requires light curtains with strong beam power and precision optics to prevent signal loss or misalignment.

· For larger openings such as wide conveyors or gantry loaders, engineers often choose a wide scanning range safety light curtain that maintains detection stability across extended horizontal distances without sacrificing beam uniformity.

Wide scanning range devices reduce the need for multiple units or complex overlapping arrangements, simplifying wiring and alignment while maintaining high safety integrity.

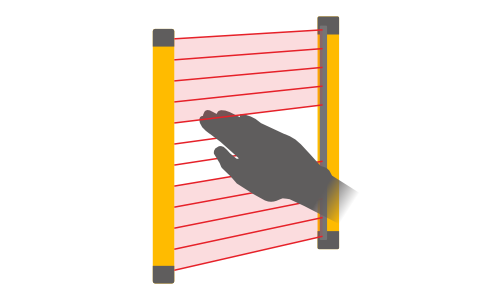

Fixed Blanking Function — Static Obstruction Handling

Fixed blanking is a configuration feature that allows specific beams within the protective field to be excluded from safety evaluation when a fixed object permanently blocks part of the detection area and cannot be removed.

Detailed Explanation

In many industrial applications, fixtures, tool holders, machine frames, or structural supports may permanently obstruct a portion of the light curtain field. Without blanking, these constant interruptions would prevent normal operation.

Fixed blanking enables engineers to:

· Programmatically disable specific beam positions during setup.

· Maintain continuous machine operation while other beams remain active for intrusion detection.

· Avoid false trips caused by unavoidable structural components.

Key considerations:

· Fixed blanking must only be applied for objects that are truly fixed and not part of normal material flow.

· A risk assessment must confirm that blanked areas do not create an unintended bypass path that operators could exploit.

· Safety control logic should verify blanking configuration at every startup to ensure ongoing integrity.

This function enhances flexibility without compromising safety when correctly deployed.

Floating Blanking Function — Dynamic Obstruction Handling

Floating blanking allows moving objects within the detection field to be temporarily ignored without disabling beams permanently.

Detailed Explanation

Unlike fixed blanking, floating blanking adapts to scenarios where objects move or change position within the protective field, such as:

· Continuously fed materials on conveyors

· Parts are being transferred or turned during processing

· Automated guided vehicles passing through the safety zone

Key attributes:

· A configurable number of adjacent beams can be allowed to be blocked anywhere within the field.

· This limit is set based on risk assessment and application requirements.

· If the number or pattern of blocked beams exceeds the allowable threshold, the system triggers a safe stop.

Floating blanking is widely used in automation, where operational efficiency requires materials to pass through the safeguarding field while still protecting humans.

Response Time — Dynamic System Timing

Response time is the time interval between a valid beam interruption and the corresponding change in the safety output signal (e.g., the OSSD switching off).

Detailed Analysis

Response time is a fundamental parameter in safety performance and directly influences safety distance calculations. A longer response time requires the light curtain to be installed further from the hazard to ensure the machine stops before any operator can reach the dangerous zone.

Response time varies with:

Protective height (more beams require longer scan time)

Internal processing speed

Safety output type (relay vs OSSD)

System architecture and self-checking logic

When designing safety systems, engineers should always use the maximum specified response time from the product datasheet — not typical values — to ensure conservative safety distance calculations. If a model with fewer beams has a 10 ms response time, a longer model with more beams may have 15 ms or higher. This difference becomes significant when calculating required safety distances.

Self-Checking and Safety Control Concepts

Self-Test Function (Type 2 / Type 4)

Safety light curtains continuously monitor their internal circuits to detect failures.

· Type 2: Periodic self-testing

· Type 4: Real-time self-monitoring (higher safety level)

Type 4 light curtains are recommended for high-risk industrial applications.

Safety Controller and Relay Integration

A safety controller receives the light curtain's output signals and converts them into safety-rated relay or controller signals, ensuring mutual safety interlocking.

For these applications, safety relays designed for machine protection systems are commonly used to achieve reliable emergency stop control.

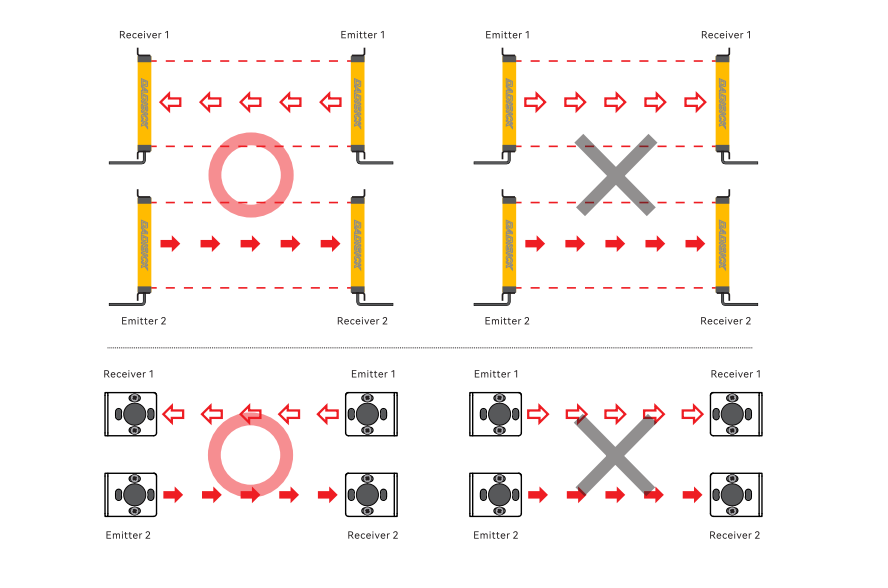

Dual-Channel Output (OSSD)

Dual-channel outputs provide two independent and synchronized safety signals. If one channel fails, the other immediately triggers a safety stop, ensuring fail-safe operation.

Manual Reset Function

After a safety interruption, the system requires a manual reset to resume operation. This prevents unexpected machine restarts and improves operator safety.

Safety Distance — The Most Critical Calculation

What Is Safety Distance?

Safety distance is the minimum distance between the safety light curtain and the hazardous zone, ensuring the machine stops before an operator can reach danger.

Incorrect safety distance is one of the most common installation mistakes.

Safety Distance Formula (ISO Reference)

Ds = K × T + C

Where:

· Ds = Safety distance (mm)

· K = Human approach speed (mm/s)

· Horizontal installation: 1600 mm/s

· Vertical installation: 2000 mm/s

· T = Total stopping time (s)

· C = Additional distance (mm), depending on resolution

Reference C Values

· Resolution 20 mm → C = 80 mm

· Resolution 30 mm → C = 130 mm

· Resolution 50 mm or above → C = 850 mm

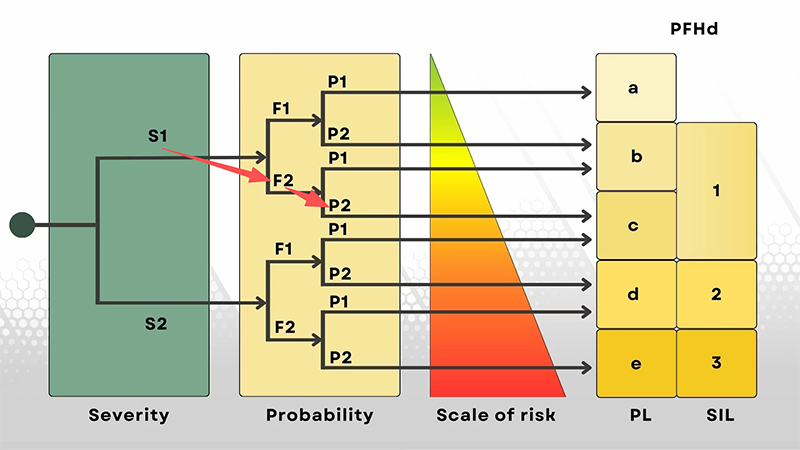

For a deeper understanding of how stopping performance and control reliability contribute to overall system safety, it is essential to consider machine safety performance levels defined under ISO 13849-1.

Conclusion — Turning Terminology into Real Safety

Understanding safety light curtain terminology is not just a technical exercise—it directly affects machine safety, compliance, and operator protection. By mastering concepts such as beam pitch, resolution, protective height, length, and safety distance, engineers can design safer systems and avoid costly safety risks.

As an engineer working in machine safety at DADISICK, this article is written based on real application experience and daily technical support cases. Correct understanding of safety light curtain terminology is the foundation for compliant design, reliable installation, and long-term operational safety.

Related Safety Devices

Beam spacing:40mm

Number of optical axes:20

Protection height:760mm

Safety sensors for machines output (OSSD):2 PNP

Multifunctional safety relay, providing automatic/manual reset configuration and multifunctional configuration DIP switch, used for industrial field monitoring of various signals with high safety requirements.

5m distance, A technique that uses a laser beam to measure distance and create detailed maps of objects and environments.

Used for monitoring places such as safety doors and windows.

Similar Posts You May Be Interested in